DPP-260R Medicine Blister Packing Packaging Machine By Rich Packing

*** PRODUCT DETAILS

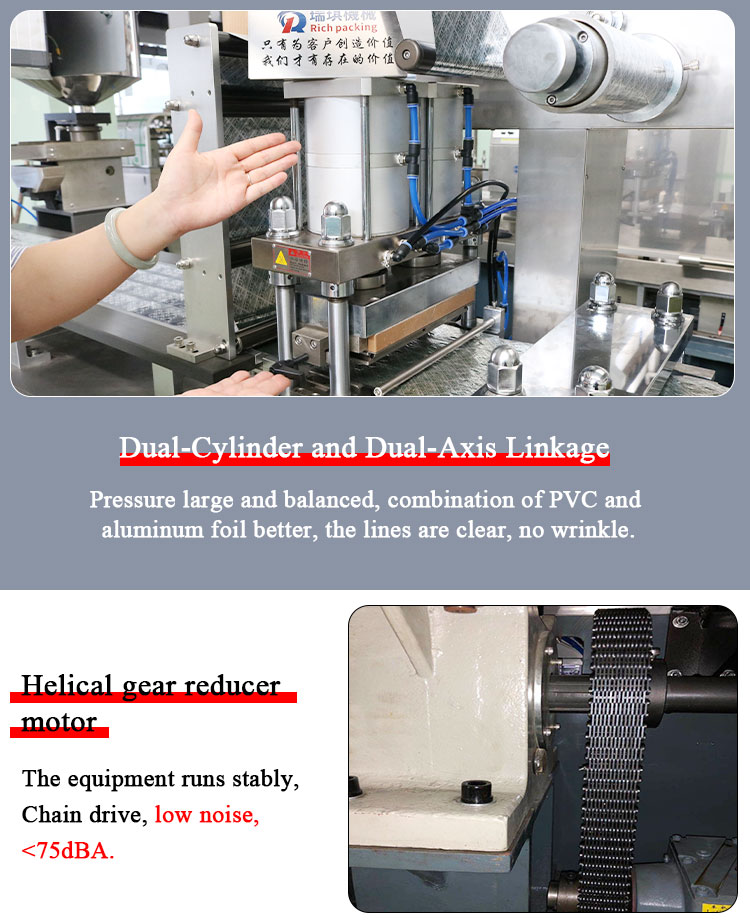

Why does our RICH PACKING's DPP series flat blister packaging machinery have a strong market share in the pharmaceutical field? These DPP 260R are a blister packing machine specially designed and made for the capsules and tablets and other medicines. All the applicable materials are not only used to package those medicines such as tablets and the capsules, but also are all suitable for packaging of the electric cigarettes vape pod in the daily necessities field, and those candies in the video industry into the aluminum-plastic or aluminum alu plates automatically.

We are not only produce the DPP flat blister machines, but also design and develop the DPH roll-type packing blister machines.

DPH is the highly speed blister machine with a higher running production speed than the DPP series.260R can be applied to more packaging types, such as the PVC outsourcing aluminum foil, and the aluminum foil outsourcing aluminum foil.

That is to say DHP is a multi purpose functions model.

With the supports of nearly 30 years of the blister packaging machine production experience and the production plant of nearly 10,000 square meters, Rich Packing have a very sufficient inventory of the semi-finished products. *** Such the conditions are sufficient to ensure that our delivery time is within 14 days. The delivery time here is mainly to customize the mold making time according to the specific needs of customers. The 260r capsules blister packaging machine has an active forming function for tablets.

*** Technical parameter

|

Model |

DPP-260R |

|

Production Capacity |

18000~236,000pcs/hour |

|

Max. Shaping Dia. And Depth |

250*160*15mmMax. Depth26mm(custom-made) |

|

Blanking |

20~180blisters/min (aluminum plastic) 20~120 blisters/min (aluminum aluminum) |

|

Power of Main Motor |

1.5kW |

|

Total Power |

6.0kW |

|

Power supply |

380V/220V/50Hz |

|

Standard Travel Range |

40~160mm |

|

Standard Plate |

80*57mm |

|

Thickness and Width of PVC |

260×0.15~0.45mm |

|

Thickness and Width of PTP |

260×0.02~0.03mm |

|

Dialyzing Paper |

50~100g*260mm |

|

Vacuum |

0.4MPa-0.6MPa |

|

gas consumption |

≥0.2m3/min |

|

Noise |

<75dBA |

|

Mold Cooling |

Runing water or circulating water It is recommended to use constant temperature cold water 60L/H |

|

Weight |

Net weight 2600kg |

|

Overall Size of Machine |

3500×740×1680 mm(L*W*H) |

***Configuration List.

|

Name |

Spec./Model |

Qty |

Manufacturer |

|

Servo Motor |

ECMA-C20807RS |

1 |

Taiwan taida |

|

server Driver |

server Driver |

1 |

Taiwan taida |

|

PLC main module |

CP1L-M30DR-A |

1 |

Omron |

|

PLC temperature module |

CP1W-TSOO2 |

1 |

Omron |

|

PLC touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Siemens |

|

Encoder |

ZSP3806-003G-1500BZ3-5-24F |

1 |

United States Rip Ann Waco |

|

Main motor |

RC series helical gear motor |

1 |

Suncheon |

|

Frequency converter |

VFD015B43A |

|

taiwantaida |

|

Stainless steel plate |

304 316 |

|

Korea,japan |

|

Switching power supply |

NES-100-24 |

|

Taiwan mingwei |

|

Positioning cylinder |

SDA32×10 |

|

AirTAC |

|

Double pressure reducing valve |

BFC4000-N |

|

AirTAC |

|

The electromagnetic valve |

4V210-08 |

|

AirTAC |

|

Pressure reducing valve |

AC2010-02 |

|

AirTAC |

|

emergency button |

XB2-BS542 |

|

Schneider |

IPv6 network supported

IPv6 network supported