DPP-130 Tablets Capsules Packaging Blister Packing Machine of Rich Packing

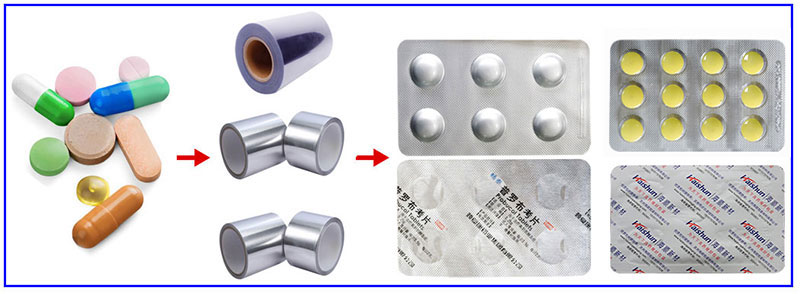

*** Application

*** Certification: SGS, CE, ISO

*** Trustworthy Factory

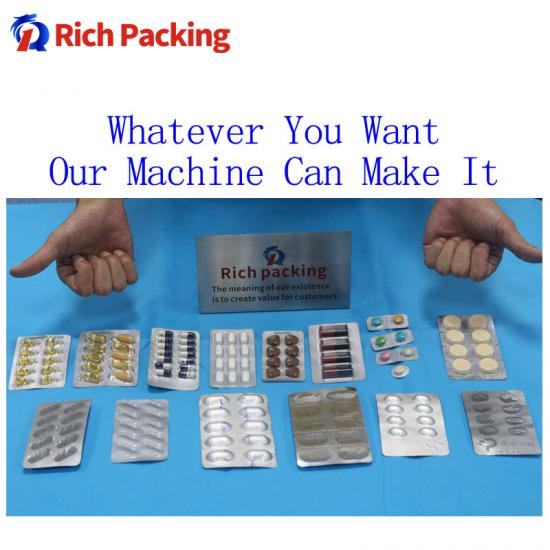

*** Rich Packing's Advantages

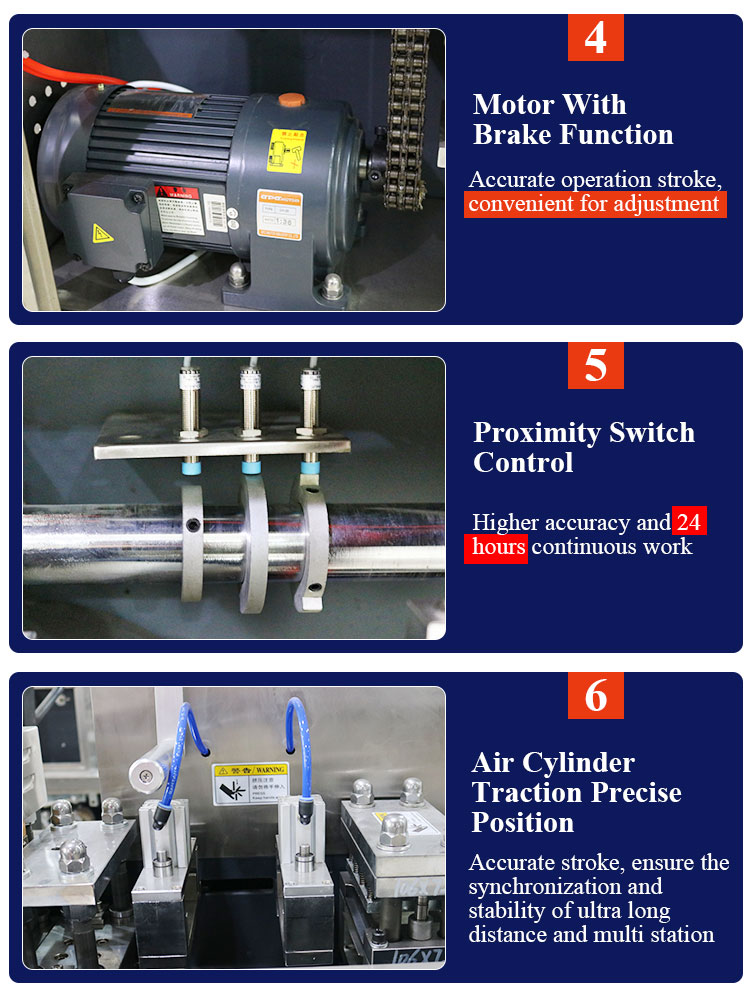

Our RQ company's DPP130 aluminum-plastic bubble cap machine is a popular product for many years, it uses high power motor. This imported motorused in DPP130 is a new type of high power gear motor which is very stable during operation.

*** the Large power motors used in dpp130. Adopt new type high of power gear motor,stable operation in dpp130.

*** DPP130 use the Chain drive position in it. this Strand chain transmission,low noise lower than 75 dBA in dpp130.

*** the better design of dpp130.Air Curved Glass Cover in DPP130 Effectively Isolate Production Process From External Environment.

*** Why should choose our's DPP130 blister packing machine?

Our RQ company's DPP130 aluminum-plastic bubble cap machine is a popular product for many years, it uses high power motor. This imported motorused in DPP130 is a new type of high power gear motor which is very stable during operation.

In DPP130 the link between the motor and the power system, we use the chain transmission method in DPP130. The advantagesDPP130of this method are that the aluminum-plastic bubble cap machine is very stable in the long-term operation process, and the noise generated is below 75dBA in DPP130.

The DPP130 uses fixed blister module guides in the heat sealing and forming stations. The advantage is that once the adjustment is in place it can be adjusted in DPP130. DPP130 is more stable than similar products from other companies. The operation reliability of DPP130 aluminum - plastic foam mask machine has also been significantly improved.

The DPP130 uses a contactless switch on the electrical side, making it more accurate and safer than pneumatic controls of DPP130.

The DPP130PLC touch screen control system often used by the operator adopts the most advanced PLC control unit in the world. All parameters in the manufacturing process are displayed directly on the DPP130's screen, which also has the function of error prompt and motor. Overload protection function in DPP130.

*** Technical parameter

| Name | Blister Packing Machine For Solid |

|

Production capacity |

4220 plates/hour |

|

Net weight of machine |

596Kg |

|

After warranty service |

video technical support, Online support, Field maintenance and repairing. |

|

Power |

380/220V 50Hz |

|

Total power |

2.45KW |

IPv6 network supported

IPv6 network supported