Categories

New Blog

Tags

When you are choosing a blister packing machine solution, you'll discover that machines equipped with servo motors offer significant advantages. This essay will delve into the benefits of these advanced systems, helping you understand why they're revolutionizing the packaging industry.

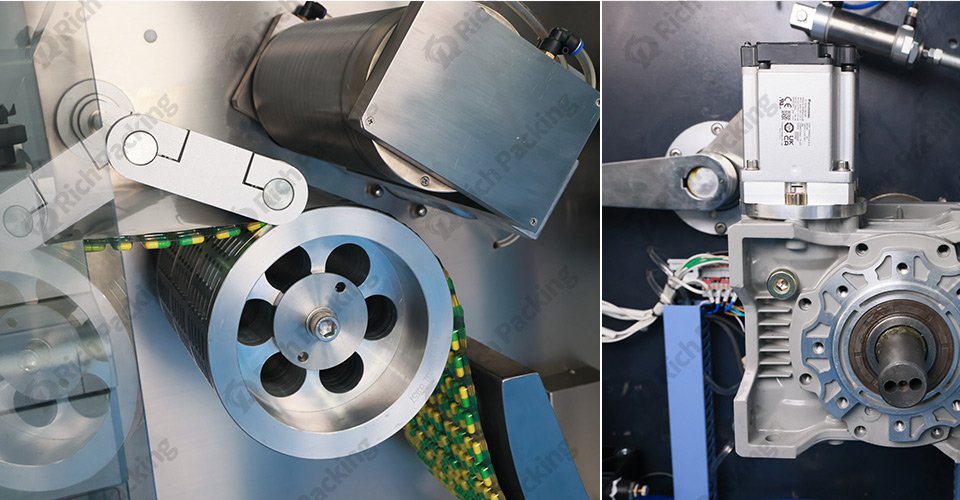

When you use a blister packaging machine with servo motors, you'll immediately notice the enhanced precision in motion control. This improvement stems from several key factors:

- Exact positioning: Servo motors can achieve and maintain precise positions, ensuring that each blister cavity is perfectly aligned during the filling process.

- Smooth acceleration and deceleration: The ability to ramp up and slow down smoothly reduces vibrations and improves overall machine stability.

- Repeatability: Servo motors can replicate movements with high accuracy, ensuring consistency across production runs.

The precision offered by servo motors translates directly into fewer packaging errors:

- Minimized misalignment: Accurate positioning reduces the risk of product misplacement within blister cavities.

- Consistent sealing: Precise control over pressure and heat application ensures uniform sealing across the blister pack.

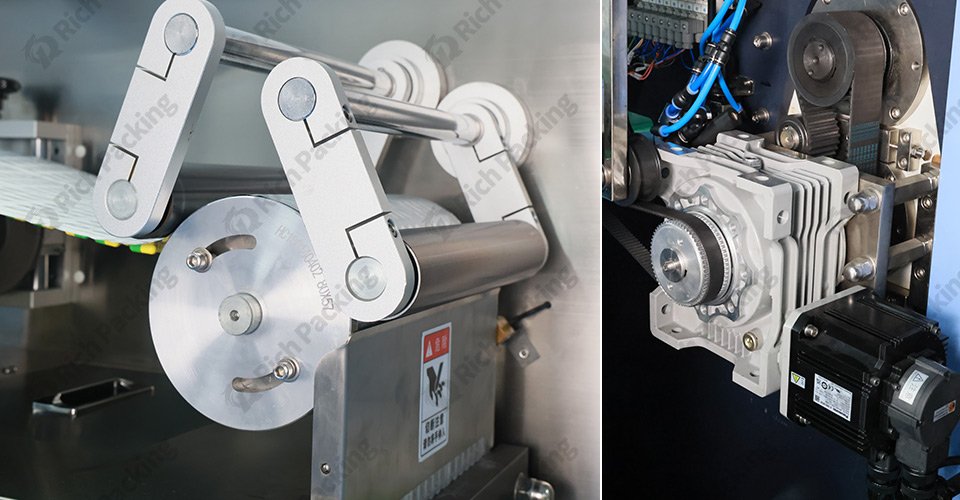

Servo motor-driven machines offer you greater flexibility when it comes to product changeovers:

- Quick adjustments: Servo motors can be rapidly reprogrammed for different product sizes and shapes.

- Reduced downtime: The ease of adjustment minimizes the time required for changeovers between production runs.

- Wider product range: The adaptability of servo systems allows you to handle a more diverse range of products on a single machine.

You'll find that servo motors enable more customized packaging solutions:

- Variable speed control: Adjust speeds for different parts of the packaging process to optimize performance for each product.

- Programmable force control: Tailor the applied force for different materials or product sensitivities.

Servo motor systems offer significant energy savings compared to traditional motor setups:

- On-demand operation: Servo motors only consume power when movement is required, reducing overall energy usage.

- Regenerative capabilities: Some servo systems can recover and reuse energy from deceleration, further improving efficiency.

- Precise power matching: The ability to provide exactly the required power for each operation eliminates energy waste from oversized motors.

The energy efficiency of servo motors also leads to reduced heat generation:

- Lower cooling requirements: Less heat production means you can reduce or eliminate additional cooling systems.

- Extended component life: Cooler operation temperatures contribute to longer lifespans for electronic and mechanical components.

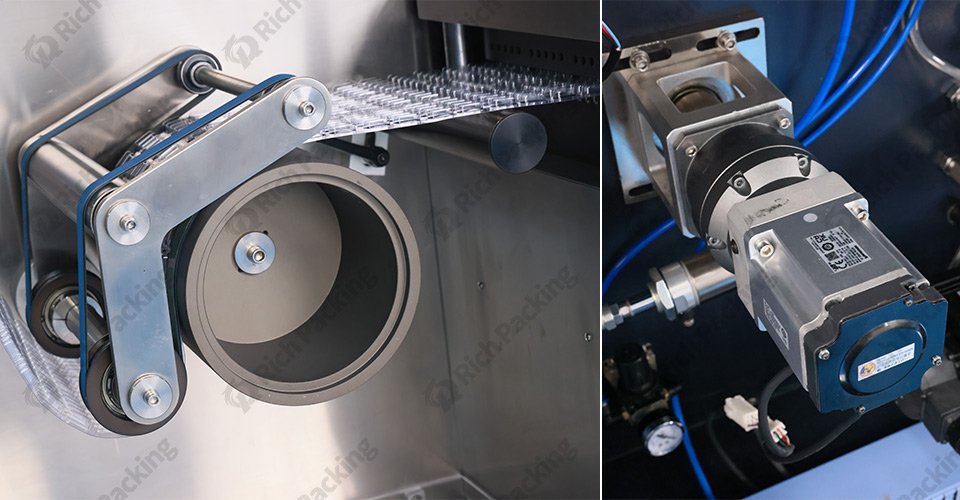

Servo motor-driven blister packaging machines can significantly increase your production speed:

- Rapid acceleration and deceleration: Servo motors can quickly reach optimal speeds and stop precisely, reducing cycle times.

- Optimized motion profiles: You can program the most efficient movement patterns for each packaging operation.

- Simultaneous multi-axis control: Coordinate multiple servo motors to perform different tasks concurrently, streamlining the overall process.

The design of servo motor systems contributes to better continuous operation capabilities:

- Reduced maintenance downtime: Servo motors typically require less frequent maintenance than traditional motor systems.

- Consistent performance over time: Unlike some conventional motors, servo motors maintain their precision and speed over extended periods.

Servo motors provide you with valuable real-time data on machine performance:

- Position feedback: Constantly monitor the exact position of each motor for precise control and error detection.

- Torque monitoring: Servo motor torque at each stage of the packaging process can be accurately feedback control system.

- Velocity data: Access detailed information on speed variations throughout the packaging cycle.

The digital nature of servo control systems makes them ideal for integration with modern manufacturing technologies:

- Data collection and analysis: Easily gather and analyze performance data for continuous improvement.

- Remote monitoring and control: Access and adjust machine parameters from anywhere, enhancing your operational flexibility.

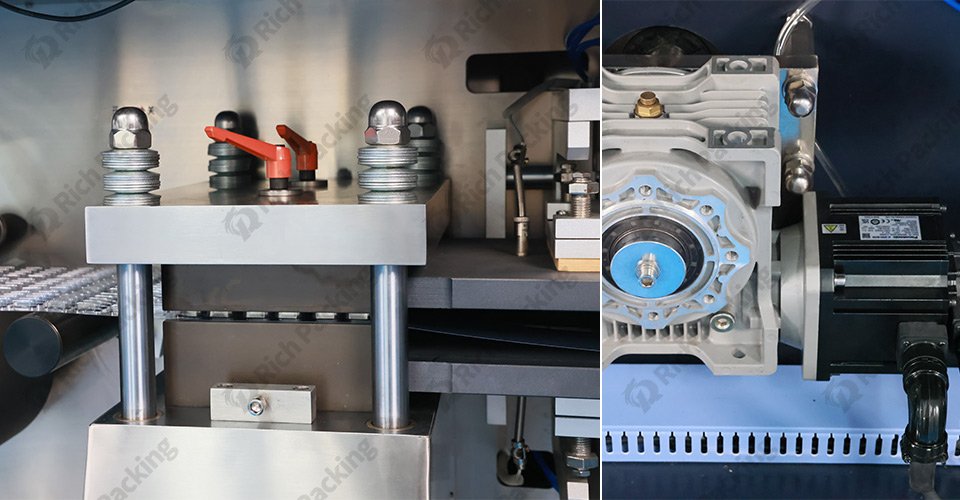

Servo motors allow you to maintain tight control over factors critical to product safety:

- Precise temperature control: Ensure that heat-sealing processes are performed at exactly the right temperature to maintain package integrity without damaging the product.

- Accurate pressure application: Apply the correct amount of pressure during forming and sealing to create secure packages without crushing delicate products.

- Controlled acceleration: Minimize sudden movements that could potentially damage sensitive items during packaging.

The precise control offered by servo systems enhances overall machine safety:

- Immediate stop capabilities: Servo motors can halt instantly when safety issues are detected, reducing the risk of accidents.

- Reduced pinch points: The ability to program complex motion patterns allows for the design of safer machine operations with fewer hazardous areas.

- Force limitation: Set maximum force thresholds to prevent equipment damage or operator injury in case of obstructions.

Servo motor-driven machines typically operate more quietly than their conventional counterparts:

- Smooth motion profiles: The ability to control acceleration and deceleration precisely reduces the noise associated with sudden starts and stops.

- Elimination of gear noise: Many servo motor applications don't require gearboxes, removing a common source of operational noise.

- Lower operating speeds: The efficiency of servo motors often allows for lower overall operating speeds while maintaining productivity, further reducing noise levels.

Reduced vibration in servo-driven systems offers several benefits:

- Improved package quality: Less vibration means more consistent forming and sealing, leading to higher-quality finished packages.

- Extended machine life: Reduced vibration puts less stress on machine components, potentially extending their operational lifespan.

By adopting blister packaging machines with servo motors, you're investing in technology that offers precision, flexibility, efficiency, and advanced control. These advantages position you to meet the evolving demands of modern packaging with confidence and competitiveness.