Categories

New Blog

Tags

In the pharmaceutical industry, large diameter tablet pressing is not an easy task. The wide amplitude and uneven pressure distribution can easily lead to various defects. If not operated properly, it may even cause serious production accidents. As an ordinary consumer, you may not be familiar with this professional knowledge. However, as a responsible pharmaceutical company, we need to share some experience with you,In order to understand the main points that need to be paid attention to in the process of using the rotary tablet press machine to produce large-diameter tablets, it helps to ensure the safety and quality of drug production.

The "Hidden Dangers" in Large Diameter Tablet Pressing

First, we need to understand the "hidden dangers" in the large diameter tablet pressing process. The main problem is the uneven distribution of the tablet material. Due to the large volume of the tablet, it is easy to have an imbalance during the feeding process, with some areas piling up too thick and others too sparse. As a result, the pressure distribution will be uneven during the pressing process. Some areas bear excessive pressure and are prone to cracking and deformation, while others have too little pressure and are difficult to achieve the expected density. The quality of the tablets produced in this way will be uneven, making it difficult to meet the drug standards.

Another hidden danger is the cracks, breakage and other defects that occur during the pressing process. The large diameter tablets have a large volume, and it is easy to have stress concentration under the pressure, leading to local cracking. Sometimes, the tablets may also be deformed due to excessive pressure fluctuations. This not only affects the appearance of the drug, but may also lead to changes in the internal structure and composition, resulting in a decline in drug quality.

Therefore, we must pay high attention to these "traps" in the large diameter tablet pressing, and take targeted countermeasures.

The "Secrets" of Large Diameter Tablet Pressing

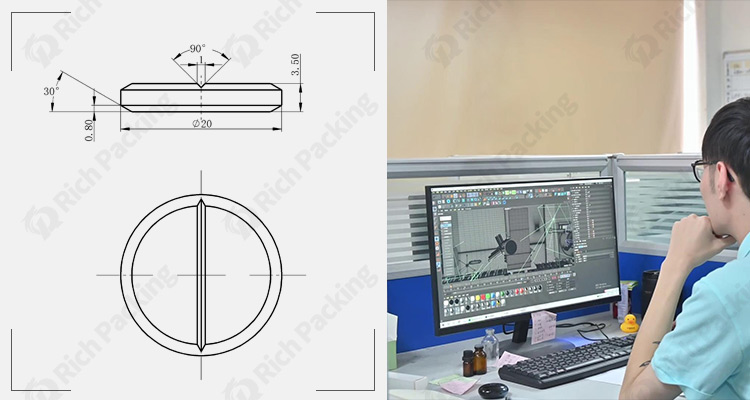

So how should we deal with these problems? The first point is to choose the pressing mold reasonably. The design of the mold directly affects the distribution of the tablet material and the transmission of pressure. We need to fully consider the flow characteristics of the tablet material, adopt a reasonable mold structure, and strive to achieve uniform distribution of the tablet material. At the same time, the strength and rigidity of the mold cannot be ignored, and we must ensure that it will not deform under high pressure.

Secondly, we need to precisely control the tablet pressing process parameters. The magnitude of the pressure, the pressing speed, the holding time, etc. will all have an important impact on the final product quality. We need to explore the best combination of process parameters through repeated experiments based on the characteristics of different products. For example, for drugs that are prone to cracking, we can appropriately reduce the pressure and increase the holding time to reduce the stress concentration. For drugs that are difficult to densify, we can appropriately increase the pressure.

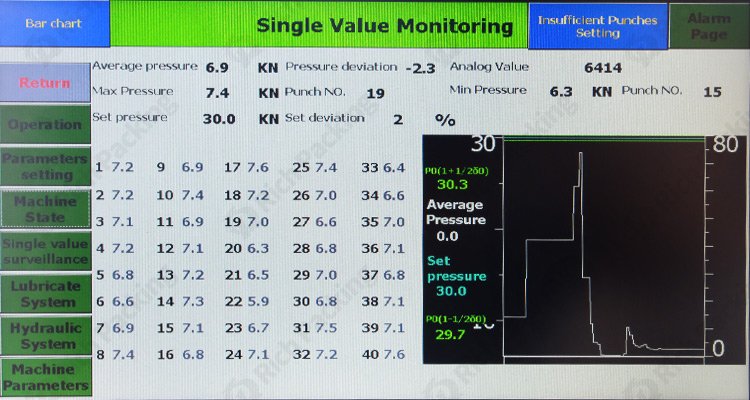

In addition, real-time monitoring and detection during the pressing process is also crucial. We can arrange pressure sensors inside the mold to monitor the pressure distribution in real time. Once an abnormality is detected, we can immediately adjust the process parameters for remediation. At the same time, we also need to strengthen the inspection of finished products, timely discover defects and eliminate them, to prevent substandard products from entering the market.

In addition to the above basic countermeasures, we have also explored some more refined optimization methods in practice.

First, further optimization of mold design. Through the combination of numerical simulation and experiments, we have repeatedly optimized the structure, materials, and other aspects of the mold, finally designing a mold that can achieve uniform distribution of the tablet material and reasonable pressure transmission. At the same time, we have also optimized the feeding system, adopting multi-point feeding and other measures to further improve the initial distribution of the tablet material.

Secondly, optimization of pressure sensor arrangement. We not only set up pressure sensors inside the mold, but also added sensors at key contact points between the mold and the tablet press. This not only allows us to monitor the pressure distribution, but also to timely detect problems with the tablet press itself, providing a basis for adjusting the process parameters.

In addition, we have also optimized the pressing speed and pressure gradient. For some drugs that are prone to cracking, appropriately reducing the pressing speed and increasing the pressure ramp-up time can effectively avoid stress concentration; for drugs that are difficult to densify, appropriately increasing the pressing speed and pressure gradient can improve the density. Of course, the adjustment of these parameters needs to be carried out in conjunction with the specific characteristics of the products through repeated experiments.

When working with many pharmaceutical companies to develop production plans, we also encounter the demand for large diameter tablets. Therefore, we have accumulated a lot of experience in large diameter tablet pressing.

For example, in the pressing process of a new drug, we found serious problems with the uneven distribution of the tablet material and the unbalanced pressure distribution, resulting in a large batch of substandard products. After in-depth analysis, we focused on optimizing the feeding system and mold design, and finely tuned the process parameters. In the end, not only were the issues of cracking, deformation and other quality problems resolved, but the production efficiency also increased significantly.

Through this case, we deeply feel that only by comprehensively controlling every link of large diameter tablet pressing can we ensure stable product quality. From mold design, process parameter optimization, to real-time monitoring and detection, each link requires meticulous care. Only in this way can we ensure the safety of our pharmaceutical company customers when using our tablet presses, while providing high-quality drugs for their patients.

As you can see, large diameter tablet pressing is indeed a process that requires "ingenuity". But as long as we research it with care, we can definitely find effective solutions. In the future, with the continuous emergence of new technologies, large diameter tablet pressing will surely become more intelligent and refined. I believe that in the near future, we will be able to develop larger diameter drugs that are even safer and more effective, allowing patients to use medicines they can trust. I hope this article has given you some inspiration. If you have any other questions, feel free to communicate with us at any time. Let's work together to make a due contribution to human health!