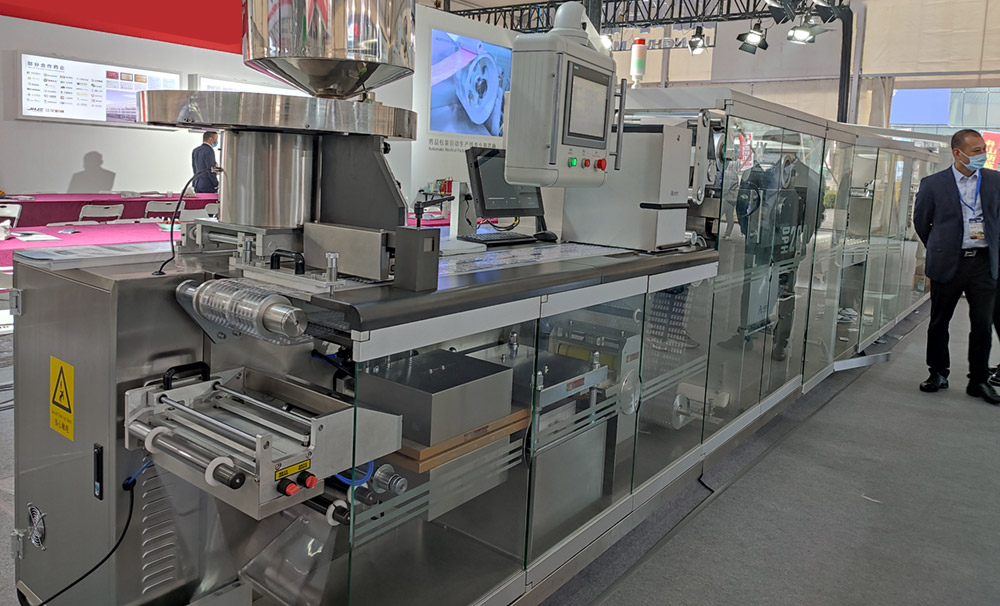

There are many forms of aluminum-plastic cartoning machines due to different manufacturers, and there are also differences in the performance levels of domestic and foreign products. At present, the existing aluminum-plastic cartoning machines can be roughly divided into the following four categories: roller continuous aluminum-plastic cartoning machines, plate-rolling continuous aluminum-plastic cartoning machines, flat-plate intermittent aluminum-plastic cartoning machines, and flat-plate continuous aluminum-plastic cartoning machines Cartoning machine.

The aluminum plastic ALU PVC cartoning machines can be distinguished by forming and hot-pressing sealing methods. The forming is divided into roller type and flat plate type. The flat positive pressure forming effects are better than the roller vacuum forming; the heat sealing is also divided into the roller type and the flat plate type hot pressing sealing effect is better than the roller type hot pressing sealing, and the roller type hot pressing sealing is in high speed, and reliability. It is more better than the flat-plate hot-press sealing.

According to the production experience, it is found that the plastic aluminum cartoning machine is prone to problems in the blister forming, hot-press sealing, etc. during using. The following briefly introduces how to solve these problems.

According to the principle that blister forming is a PVC film (hard sheet) heated through a mold and compressed air or vacuum formed into a blister of the required shape and size, when there is a problem with the formed blister, it is necessary to start from the following aspects solve:

(1) Whether the PVC film (hard film) is a qualified product;

(2) Whether the temperature of the heating device is too high or too low;

(3) Whether the surface of the heating device adheres to PVC;

(4) Whether the molding die is qualified, whether the molding hole is smooth, and whether the air hole is unobstructed;

(5) Whether the compressed air of the flat positive pressure molding is clean and dry, whether the pressure and flow can reach the normal value, and whether there is abnormal loss of the pipeline;

(6) Whether the vacuum degree and exhaust rate of roller negative pressure molding can reach the normal value, and whether there is abnormal loss of the pipeline;

(7) Whether the cooling system of the forming mold in blistering machinery is working normally and effectively;

(8) Whether the flat plate positive pressure forming molds clamps the PVC belt in parallel, and whether there is air leakage.