How To Plan And Design The Control System Of The Counting Machine?

Jun 11, 2022

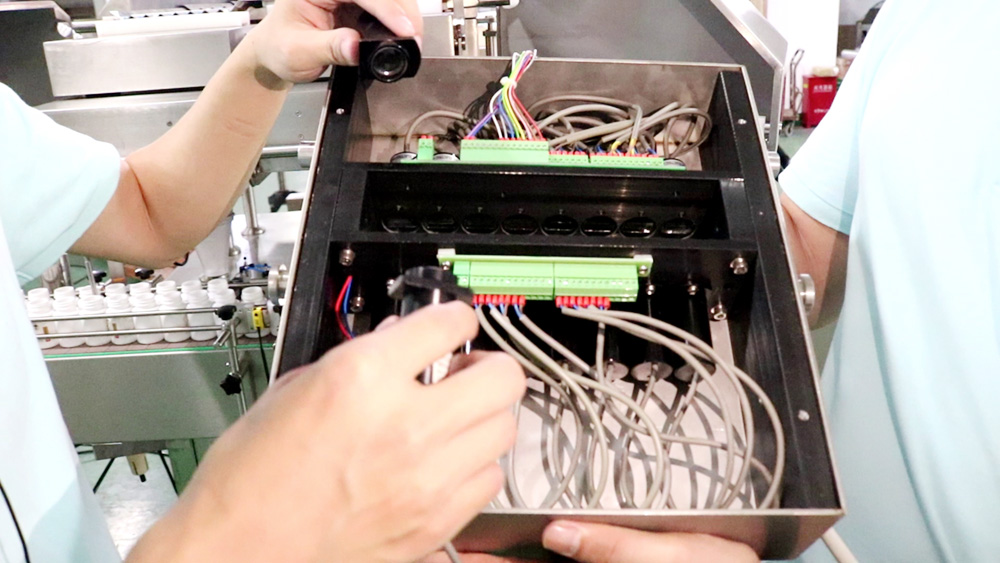

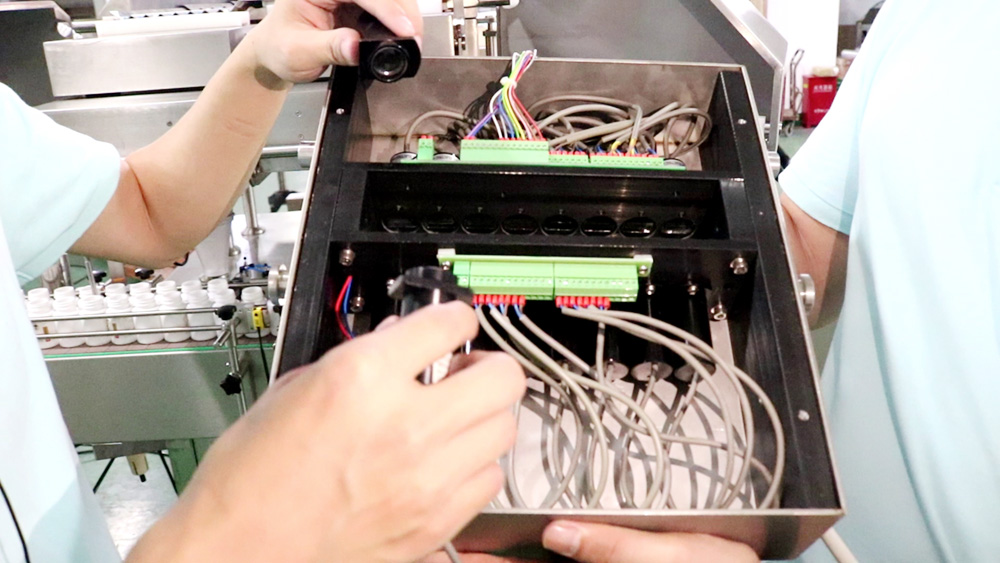

According to the operation process of the counter counting machine and the requirements of high precision and rapid response, RICH PACKING has planned a professional-level centralized control system in combination with the industry. The production process is controlled. The operator must have an understanding of the composition, function, task rationale and operation process of the equipment control system.

At the same time, the accurate counting of the drug particle counting detection system and transparent capsules is the difficulty in the operation of the counting machine, and it is also the foundation to ensure the accuracy of the counting. RICH PACKING gives the principle of self-organizing competitive neural network, operation process, system operation consequences, CCD operation sequence diagram and priority determination algorithm. The control system has high counting accuracy, fast running speed and stable running.

Features of the counting machine:

When bottles are fed, no bottles, bottles are discharged, or bottles are piled up, the counting plate automatically stops running, does not perform counting operations, and still adheres to the start mode. When the bottle is out of the bottle, the machine automatically resumes counting operation.

The counting machine is equipped with active safety maintenance equipment to avoid unnecessary waste. When the empty bottle does not reach the production homework, the host is in a pause mode. When you arrive at homework, it will be activated automatically to ensure the accuracy of counting and bottling during the production process.