Blister Packaging and Cartoning Machine

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

| Name | Rich Packing DPP270max ZH130W Blister Cartoning Line |

| Capacity | 125 cards/h |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

The RICH PACKING Blister Packaging Cartoning Machine Line

equipped with multiple advanced features, meeting the high-efficiency, precision, and stability requirements of modern pharmaceutical companies for packaging.

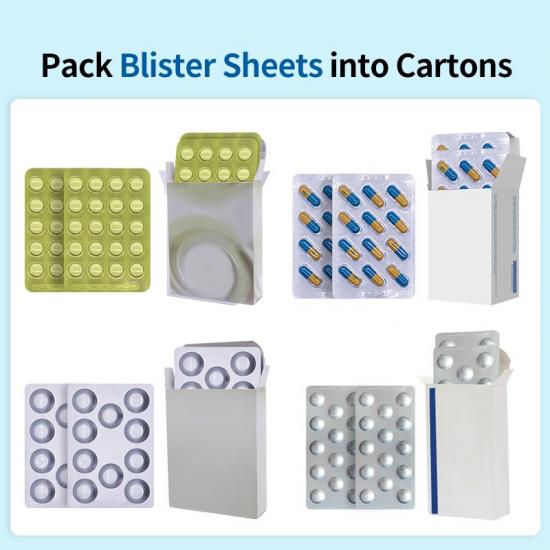

Wide Applicability of Blister Cartoner

Suitable for packaging and cartoning various capsules and tablets in aluminum plastic blister packs and aluminum aluminum blister packs, as well as pharmaceutical ampoules, vials, and other materials. Whether for conventional pharmaceutical packaging forms or special shaped pharmaceutical packaging, the RICH PACKING Blister Packaging and Cartoner Machine Line can meet the packaging needs, offering strong versatility and adaptability.

Dual-Machine Intelligent Linkage

Achieves seamless integration between the blister packaging machine and the fully automatic blister cartoning machine. The intelligent control system coordinates the operational rhythms of both machines, ensuring smooth material transfer between different processes and eliminating errors and efficiency losses caused by manual intervention. For example, during blister carton packing production, after the blister packing machine completes operations such as blister forming, filling, heat sealing, and cutting, it precisely transfers the blister packs to the horizontal cartoning machine, which then performs a series of operations including insert folding, carton forming, loading, and sealing. The entire carton packing process is seamless, significantly improving production efficiency.

High-Efficiency Production

Requires fewer operators during production, with precise material feeding. High-precision mechanical components and advanced sensor technology ensure accurate material transfer between processes, reducing errors and material waste caused by human factors. Additionally, real-time production monitoring and display functions are provided. Operators can use the monitoring system to track the production line's operational status, progress, and equipment parameters in real time, promptly identifying and resolving issues to ensure continuous and stable production.

Blister Cartoner with Easy Maintenance

The blister packaging and cartoning production line is very simple to maintain. Mold installation and removal can be completed in just 14 minutes, significantly reducing maintenance costs and downtime. This quick mold change design allows rapid switching between different product specifications, enhancing equipment utilization and production flexibility. Moreover, the equipment's structural design is rational, making it easy to clean and maintain, complying with the cGMP standards of the pharmaceutical industry, and ensuring hygiene and safety during production.

Reduced Labor Intensity

Simplifies tedious operations such as replacing packaging materials, adding inserts, and loading materials into cartons. Cartoner operators can perform these tasks via Siemens touchscreen PLC controls, enabling continuous and stable operation of the entire cartoning line. This design greatly reduces labor intensity, alleviates the workload of operators, and improves automation and efficiency. For example, traditional packaging production lines require manual tools like wrenches to disassemble molds for material changes, which is time-consuming and labor-intensive. In contrast, the RICH PACKING Blister Packaging and Cartoning Line employs modular quick-change mold technology, allowing material changes to be completed in just 14 minutes, minimizing downtime and boosting production efficiency.

High-Precision Automated Control System

DPP 270Max and ZH 130W blister carton packaging machine line uses a self-developed high-precision PLC control system to ensure precise operations in every production step, thereby improving product quality and consistency. For instance, during blister packaging, parameters such as heating temperature, forming pressure, and heat-sealing time are precisely controlled to guarantee blister forming quality and sealing performance. During cartoning, parameters like loading position and insert folding accuracy are meticulously managed to ensure cartoning precision and aesthetics.

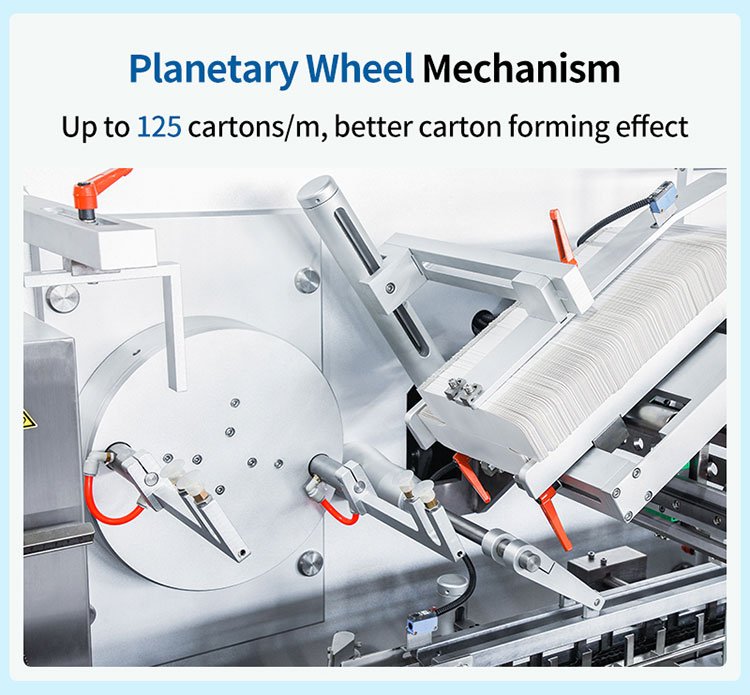

Technical Advantages in Rich Packing Cartoning Machine line

Precise Material Feeding

High-precision mechanical components and advanced sensor technology ensure accurate material transfer between processes, reducing errors and waste caused by human factors. During production, feeding precision directly impacts efficiency and product quality. The RICH PACKING Blister Packaging and Cartoning Line achieves precise feeding, ensuring continuous and stable production while improving efficiency and product yield.

Real-Time Production Monitoring and Display

Provides real-time monitoring and display functions. Operators can track the production line's operational status, progress, and equipment parameters via the monitoring system, promptly identifying and resolving issues to ensure continuous and stable production. This feature not only enhances efficiency but also reduces downtime caused by equipment failures or operational errors, improving equipment utilization.

High Production Capacity

The RICH PACKING Blister Packaging and Cartoning Line offers high production capacity, meeting the demands of large-scale production. For example, the blister machine's punching frequency can reach 60 strokes per minute (for aluminum-plastic blister packaging), and the cartoning machine's maximum capacity can reach 130 boxes per minute. This high-capacity design enables the production line to complete large-volume packaging tasks in a short time, enhancing the company's production efficiency and market competitiveness.

Rich Packing's Customer Service

RICH PACKING provides comprehensive, high-quality services to ensure smooth and efficient production for customers using the Blister Packaging and Cartoning Line. After equipment delivery, the company arranges professional technicians to perform on-site installation training and debugging, ensuring proper operation. Additionally, detailed training services are offered to help customers' operators familiarize themselves with equipment operation and maintenance procedures, reducing equipment failures and production delays caused by improper operation.

For after-sales service, RICH PACKING has established a robust customer service system to promptly address customer needs. When equipment failures or technical issues arise, the company quickly dispatches technicians for on-site repairs and solutions, ensuring normal operation. Regular follow-ups are conducted to monitor equipment performance and customer needs, providing timely technical support (including manual files and videos) and improvement suggestions. This comprehensive service not only enhances customer satisfaction but also strengthens loyalty to the RICH PACKING brand.

Summary

The RICH PACKING Blister Packaging and Cartoning Line DPP 270max and ZH 130W, with its high automation, efficient production, user-friendly operation, superior product quality, and wide applicability, stands as an ideal packaging solution for modern pharmaceutical companies and related industries.

IPv6 network supported

IPv6 network supported