HZP-26-40D High Speed Rotary Tablet Press

*** Technical parameter

|

Model |

HZP-26/40D |

|

Max. Production Capacity |

260,000 pcs/h |

|

Main Pressure |

100 kN |

|

Pre Pressure |

21 kN |

|

Max. Dia. of Tablet |

25 mm |

|

Max. Thickness of Tablet |

10 mm |

|

Rotary Speed |

10-110 r/min |

|

Motor |

7.5kw |

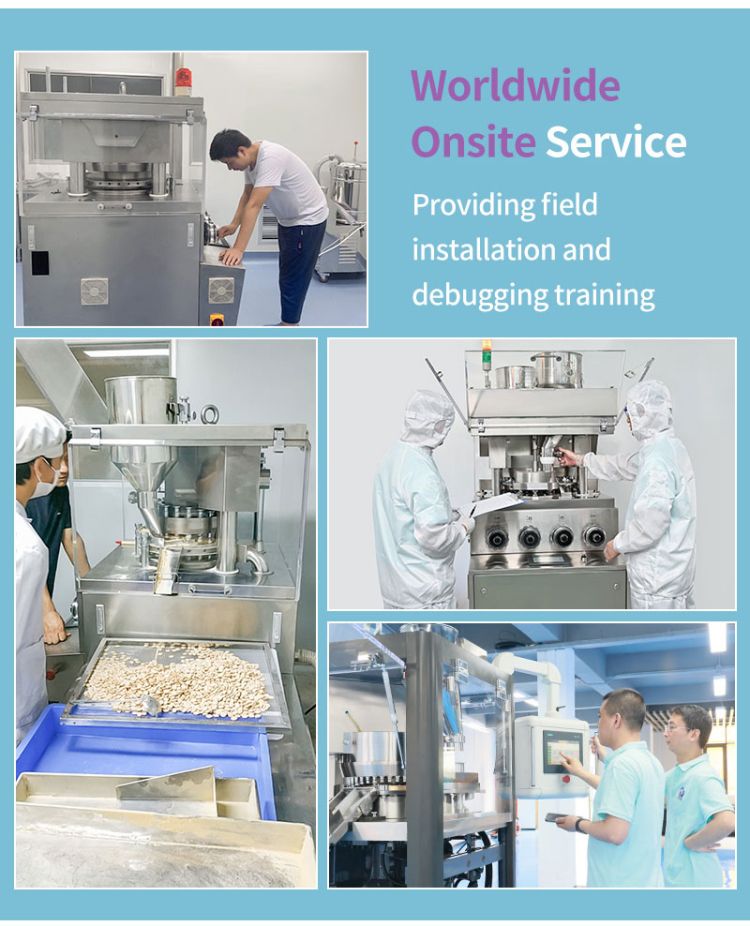

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

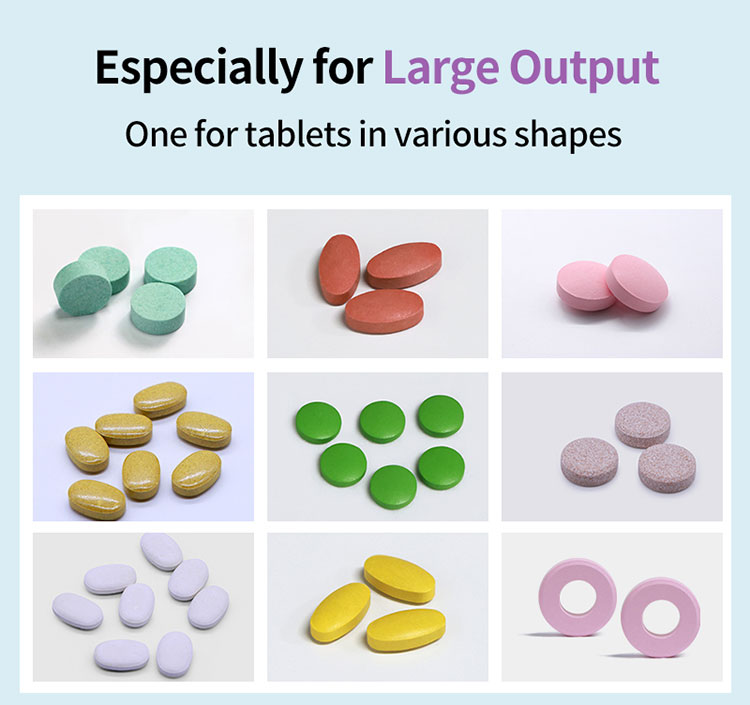

Rotary Tablet Press Machine: Why the HZP-26/40D is the Scientific Choice for High Throughput and Weight Stability

Introduction: The Tablet Press Machine’s Engineering Paradox of Speed and Precision

In modern pharmaceutical and nutraceutical manufacturing, production managers face a persistent engineering paradox: how to increase production speed without sacrificing tablet weight stability and hardness?

In standard tablet presses, as production speed increases, the "dwell time" (the time the punch maintains maximum pressure) decreases. This often leads to common defects such as tablet lamination, cracking, and excessive weight variation. For high-volume manufacturers, the goal is not simply a faster machine, but one that can maintain precision at high speeds using intelligent feedback loops.

The HZP-26/40D high-speed rotary tablet compression machine from Rich Packing is the answer. It's not just a piece of equipment; it's a comprehensive solution to the physics of powder compression. By integrating servo-driven control, an AI-based rejection system, and a unique pre-compression structure, the HZP-26/40D redefines the capabilities of pharmaceutical tablet presses.

6 Core Advantages of the HZP-26 40D High Speed Tablet Press

1. The Physics of Pre-compression: Maximizing Dwell Time and Plasticity

The most critical stage in tablet formation is the consolidation of powder particles. In basic pill tablet presses, trapped air between particles can cause tablets to "delaminate" (crack) when the pressure is released too quickly.

The HZP-26/40D tablet machine addresses this problem with an advanced pre-compression system.

The scientific principle: Before the main compression, the powder undergoes a preliminary compaction stage. This serves two crucial scientific functions:

Air Removal: It mechanically expels interstitial air from the die and powder bed. If this air is not removed before the main pressure is applied, it becomes compressed air within the tablet, acting like a spring and causing the tablet to crack upon ejection.

Enhanced Plasticity: Pre-compression rearranges the particles, increasing their contact points. This improves the "plasticity" of the powder, making it more receptive to the final binding forces. By effectively extending the total compression time, the HZP-26/40D can produce harder and stronger tablets even at high operating speeds, thus solving the inherent trade-off between speed and quality in traditional rotary tablet presses.

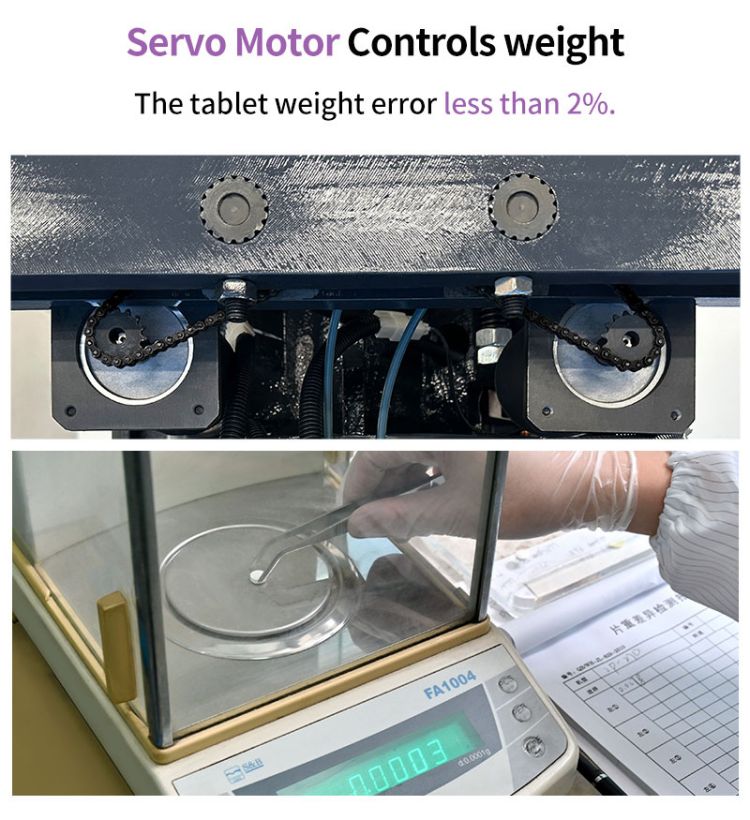

2. Servo-driven Weight Control: Saying Goodbye to the Handwheel Era

In traditional tablet production, adjusting tablet weight requires the operator to manually turn a handwheel, a method prone to human error and mechanical play. The HZP-26/40D tablet compress machine completely changes this with its servo motor automatic adjustment system.

Automation for High Precision

The machine completely eliminates the mechanical handwheel. Instead, a high-precision servo motor controls the filling guide.

● Closed-loop feedback: This system is not a "set it and forget it" system. It continuously monitors the filling position.

● Automatic compensation: If the system detects a trend of weight fluctuations due to changes in powder density, the servo motor will automatically adjust the height of the filling cam with micron-level precision.

This automatic tablet compressor ensures that the filling volume is dynamically adjusted to reach the set target value. The result is significantly reduced weight fluctuations, with average tablet weight accuracy consistently maintained at ≤±2%.

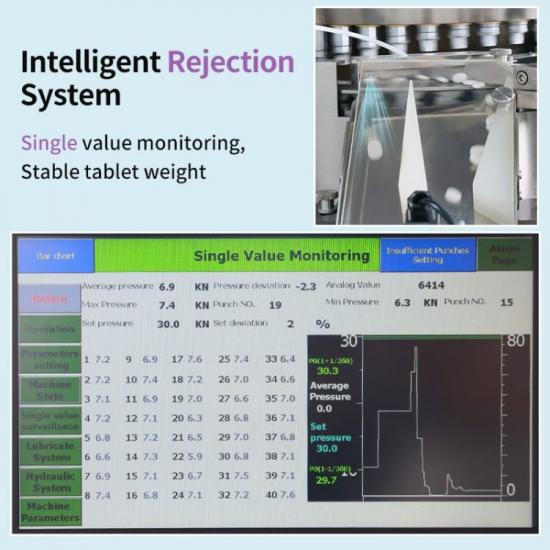

3. Real-time Pressure Monitoring: The "Brain" of the Rotary Tablet Press

The weight of a tablet is directly related to the compression force required for its formation. If there is more powder in the die, the pressure will increase; if there is less powder, the pressure will decrease. The HZP series tablet machines utilizes this physical principle and is equipped with a on time pressure monitoring.

In this closed-loop control system, sensors on the main compression roller monitor the main compression force and deviation for each tablet.

Data analysis: The PLC analyzes the pressure curve of each compression.

Instant correction: If the pressure deviates from the standard curve, the system infers that the filling depth has changed. It then sends a signal to the filling servo motor to correct the dosage for subsequent tablets.

This feature transforms this equipment from a simple tablet press into a smart manufacturing node. It can proactively correct errors before they escalate into statistical failures, ensuring stable tablet weight (CPK value) throughout the entire batch.

4. AI-Driven Rejection System: From Batch Rejection to Single-Tablet Precision

Quality assurance in high-speed production typically relies on random sampling. However, sampling cannot detect all defects in a batch of millions of tablets. The HZP-26/40D addresses this problem with an AI-driven reject system integrated with the pressure monitoring system described above.

Single-Tablet Identification

Unlike older systems that might reject an entire section of the production line when a fault is detected, this rotary tablet press utilizes high-speed logic gates.

● Logic: When the pressure sensor detects a pressing action that is "out of specification" (too light or too heavy), it tracks the tablet's position on the turntable.

● Action: When the tablet reaches the discharge chute, a high-speed pneumatic gate activates, rejecting only the single defective tablet.

This allows the machine to perform both continuous rejection (in case of systematic errors) and precise single-tablet rejection. The result is a significantly higher "pass rate" for the final batch, as the machine effectively acts as its own 100% inspection system.

5. Eco-Friendly Transformation: Powder Recycling and Yield Efficiency

One hidden cost in the operation of any press tablet machine is the "tailings" or excess powder that spills from the feeder during high-speed rotation. In standard machines, this powder typically accumulates on the turntable, risking cross-contamination or waste.

Two Advantages of the Recycling Ingredient System

The HZP-26/40D with a residual recycling powder.

● How it works: A dedicated powder return turntable collects the excess material flowing from the feeder gaps. Driven by the kinetic energy of the main turntable, this powder is automatically returned to the feeding system for reuse.

● Advantages: This creates a "clean turntable" environment. By keeping the die table free of loose powder, we reduce the risk of friction and "sticking." More importantly, it maximizes the utilization of raw materials, which is crucial for pressing expensive pharmaceutical formulations.

6. Extended Service Life: Innovative Die Assembly Translation System

One of the common mechanical failure points in any tablet making machine is the continuous impact of the upper and lower punches on the inside of the die during material compression. Because the punch consistently strikes the die at the same point, metal fatigue occurs rapidly in this concentrated area, leading to die deformation over time.

The HZP-26/40D introduces a unique engineering innovation: a die overall translation system.

This system disperses the impact load on the die.

It allows the upper and lower main compression rollers and the upper and lower dies to move equidistantly.

● Concept: By cleverly changing the contact point during tablet formation, the machine distributes wear to a larger area of the die.

● Result: This prevents the formation of deep wear grooves. It significantly extends the lifespan of both the die and the punch.

From a total cost of ownership (TCO) perspective, this feature alone makes the HZP-26/40D a more worthwhile investment than standard rotary tablet presses.

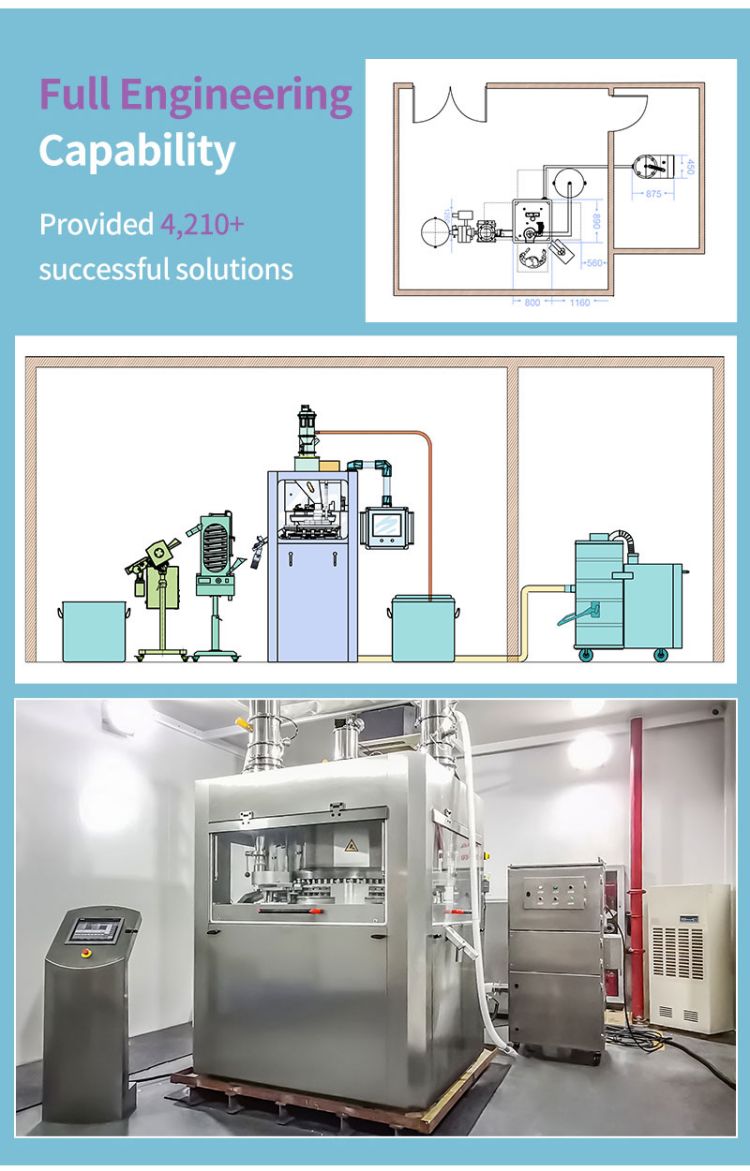

Conclusion: The HZP-26/40D is the future of tablet presses

The HZP-26/40D high speed rotary tablet machine represents the fusion of mechanical robustness and digital intelligence. Through scientifically sound engineering design, it addresses fundamental issues such as air entrapment, weight fluctuations, and mechanical wear, making it the ideal choice for manufacturers seeking high production yields. Whether you want to scale up production or reduce material waste, the HZP-26/40D provides the stability and precision required for modern pharmaceutical manufacturing excellence.

The turntable of the HZP-26-40D rotary high speed tablet press is made of high strength 2Cr13 austenitic stainless steel, combined with mixed tin QT600, with a surface hardness of HRC53 or above.

The integrated tablet weight automatic adjustment system does not require hand wheel adjustment. The Siemens servo motor controls the filling track, and the system automatically increases and decreases compensation. The average tablet weight accuracy of the tablet press is ≤±2%.

Our high-speed tablet press monitors the pressure of each die in real time, and is equipped with a real-time online detection and rejection system to automatically identify and promptly reject products with unqualified tablet weights. It can achieve batch rejection and accurate single-piece rejection.

This cutting edge series of rotary tablet presses is equipped with a residual powder recycling system. The powder return turntable recycles the residual powder that flows out to the forced feeder, and there is basically no powder residue on the disk.

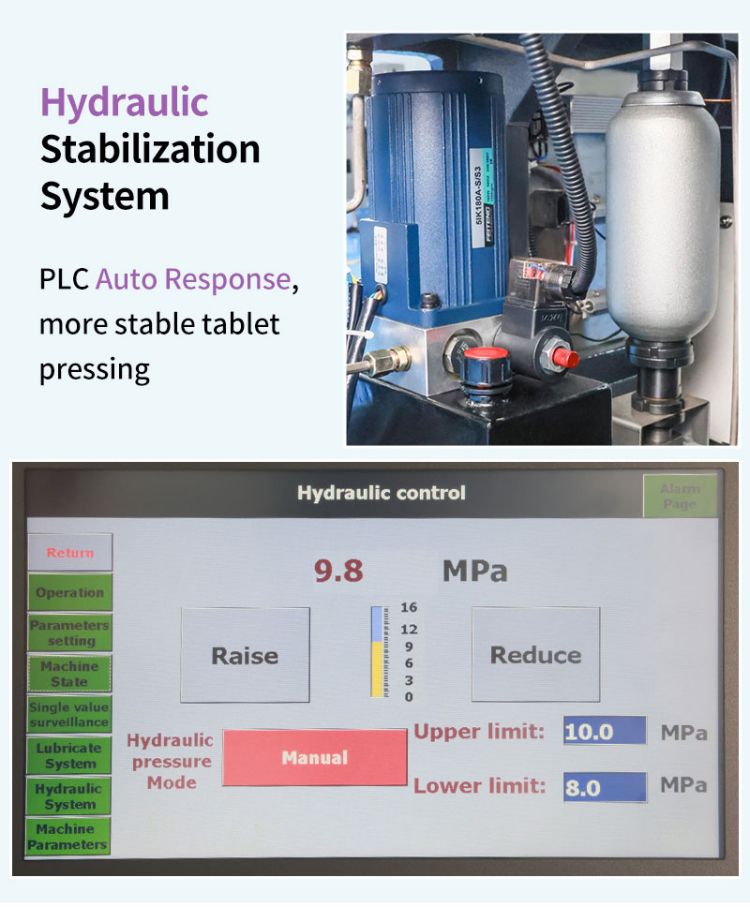

The hydraulic pressure stabilization system makes the weight of tablets produced by this tablet press stable, because the standard pressure hydraulic stabilization device, the plc automatically responds, the hydraulic pressure is stable, the stability of tablet pressing is improved, and the noise is low.

Our high capacity automatic tablet press is equipped with a truly intelligent lubrication system, which realizes the automatic sealed oil supply function of liquid and solid lubricants, and automatically lubricates the molds, guide rails, pressing wheels, bearings, etc.

IPv6 network supported

IPv6 network supported