NJY 300C Oil Capsule Liquid Filling Machine

*** Technical parameter

|

Production capacity |

20000 pcs/h |

|

Power |

380V/220V 50/60Hz |

|

No.of segment bores |

6 |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule 99.9% Full capsule 99.8% |

|

Filling error |

≤2% |

|

Applicable product |

00-3# gelatin capsule, methyl cellulose, plant capsule |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Technical Advantages of the Rich Packing NJY 330C Liquid Capsule Filling Machine

Compatibility with Diverse Capsule Types and Filling Techniques

The NJY 330C liquid capsule filling machine provides exceptional flexibility in capsule type and filling technique compatibility, catering to the diverse requirements of the pharmaceutical and healthcare product industries.

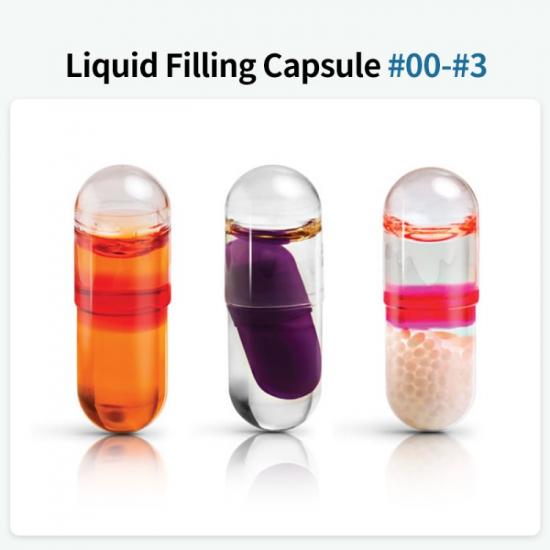

Capsule Type Compatibility: This liquid capsule machine encapsulates liquid ingredients—including oils, solutions, suspensions, and pastes—into standard-sized capsules (000-3#). It is compatible with gelatin, hydroxypropyl methylcellulose (HPMC), and plant-based capsules. This broad compatibility enables companies to produce varied product lines on a single machine, minimizing equipment investment and production costs. E.g., manufacturers producing diverse pharmaceuticals and healthcare products can seamlessly switch between capsule types to accommodate different product specifications.

Versatile Filling Techniques: The capsule filling liquid machine supports multiple liquid capsule filling methods, such as single oil filling, micro-pellet oil filling, and small capsule oil filling. This versatility offers greater production options and meets varying product process requirements. The large platform design accommodates optional auxiliary feeding devices, such as pellet and capsule feeding stations, significantly enhancing the machine's flexibility and utility. E.g., when producing pellet-containing pharmaceuticals, an optional pellet feeding station enables precise pellet filling and oiling, improving product quality and consistency.

Precise Metering and Drip Control

The NJY 330C oil capsule filling machine excels in precise metering and drip control, a cornerstone of its technological superiority.

High-Precision Metering: Utilizing a high-precision Japanese ceramic pump and Schneider servo system, the machine achieves milliliter-level dosing accuracy of less than ±2%. This precision is critical for the pharmaceutical and health supplement industries, where strict control over active ingredient dosage is essential for efficacy and safety. E.g., for drugs with low bioavailability and poor water solubility, precise metering ensures each capsule meets the specified active ingredient content standard, enhancing therapeutic effect.

Effective Drip Control: Two dedicated servo motors govern the filling process: one controls liquid addition, the other manages liquid backflow, effectively eliminating dripping. Dripping compromises production hygiene, product quality, and results in material waste.

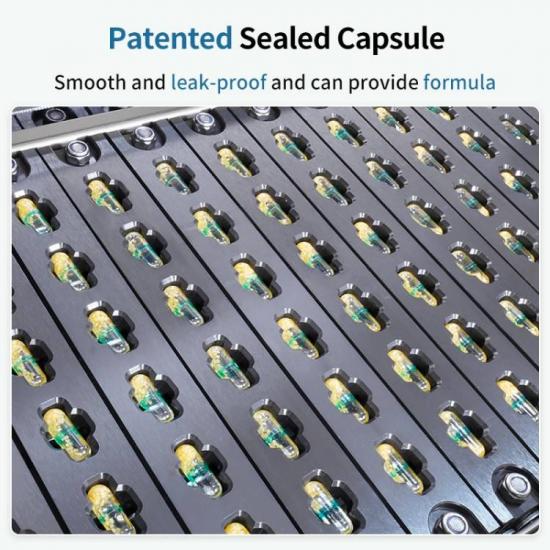

Customizable Sealing Adhesive Formula and System

The NJY 330C liquid encapsulation machine's sealing technology offers high flexibility and reliability, tailored to different capsule requirements.

Rich Packing provides customized sealing adhesive formulas based on customer capsule type, ensuring a tight, leak-proof seal. This customization accommodates various capsule materials (gelatin, HPMC, plant-based), meeting diverse pharmaceutical and healthcare needs. E.g., animal-based gelatin capsules utilize a dual-sealing wheel system, while plant-based capsules employ a single sealing wheel. This precise matching enhances seal quality, minimizes adhesive waste, and reduces production costs.

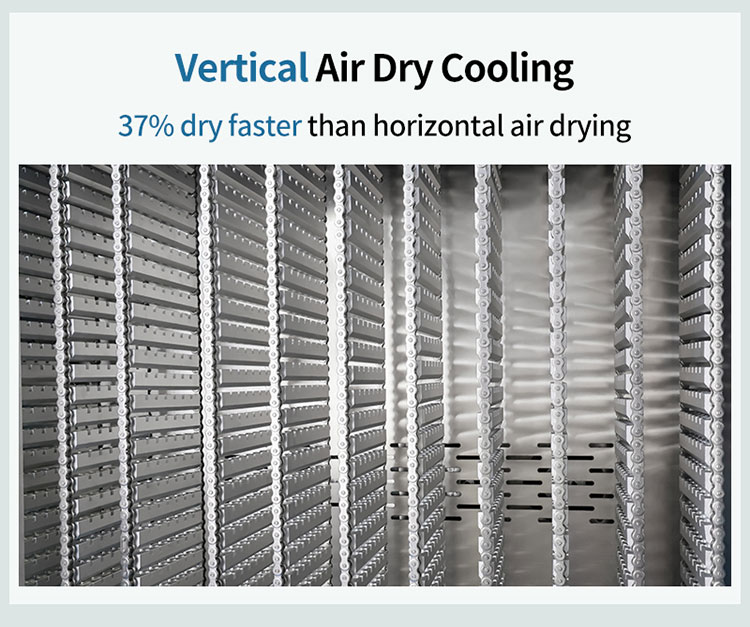

Enhanced Capsule Drying Efficiency

The capsule drying system is a key technical feature of the NJY 330C liquid capsule filling and sealing machine, significantly boosting production efficiency and product quality.

Vertical Air Drying System: Utilizing a vertical air drying method, this system delivers a 78% increase in efficiency compared to conventional horizontal systems. This design maintains capsule stability during drying. Vertical airflow ensures uniform hot air distribution across the capsule surface, accelerating solvent evaporation and shortening drying time, thereby improving productivity and reducing energy consumption. Fan cooling rapidly lowers capsule temperature, preventing deformation or damage and ensuring quality and stability.

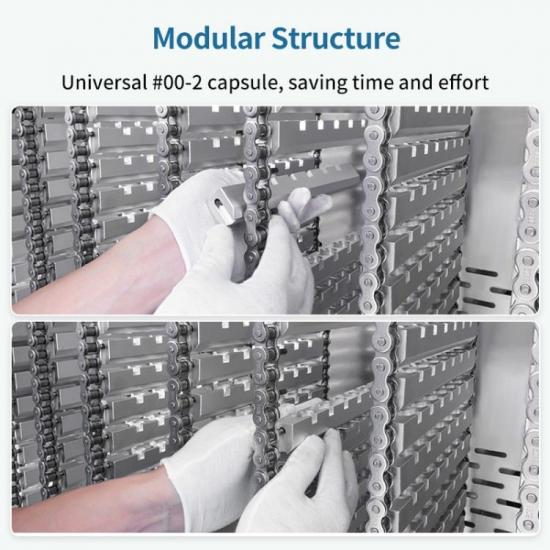

Versatile Mold Design & Rapid Changeover: The drying mold accommodates #0-2 capsules without changeover, saving significant time. Furthermore, an innovative modular design enables installation or removal of a single mold in just 5 seconds. This enhances machine flexibility, minimizes production interruptions, improves efficiency, and simplifies mold maintenance and replacement, reducing downtime and costs.

Intelligent Capsule Feeding and Monitoring

The NJY 330C automatic liquid filling capsule machine demonstrates advanced intelligence in capsule feeding and monitoring, elevating production efficiency and product quality.

The intelligent capsule feeding mechanism features upper (full point) and lower (empty point) detection sensors. When capsules reach the upper point, the feeding wheel accelerates; upon reaching the lower point, it decelerates. This mechanism ensures continuous operation, preventing interruptions or failures due to insufficient or excessive capsule supply. E.g., during high-speed production, real-time monitoring and speed adjustment guarantee a stable capsule flow, enhancing throughput and equipment stability.

Streamlined Cleaning and Maintenance

The NJY 330C liquid oil capsule filling machine excels in ease of cleaning and maintenance, improving usability and operational efficiency.

The liquid injection station employs a mobile feeding design with an integrated automatic cleaning function. Operators initiate a single-click PLC command to effortlessly clean and remove residual oil. This automation improves efficiency and reduces the difficulty and time associated with manual cleaning. E.g., when switching between different liquid ingredients, the PLC cleaning command ensures the dosing system is automatically cleaned, maintaining equipment hygiene and product quality.

Compliance with International Production Standards

The NJY 330C liquid capsule filling machine fully automatic complies with internationally recognized certifications: FDA (U.S. Food and Drug Administration), UL (Underwriters Laboratories), CE (European Community), and cGMP (Good Manufacturing Practice). These certifications attest to the equipment's high standards in quality control, manufacturing processes, and safety. They provide a foundation for pharmaceutical and health product companies to access international markets. The NJY 330C effectively prevents contamination, cross-contamination, and errors during production, ensuring consistent, high-quality output.

High Operational Stability

The NJY 330C automatic liquid capsulator incorporates globally renowned core components, guaranteeing high performance and long-term reliability.

Schneider PLC System: This highly stable and user-friendly system precisely controls operational processes, enabling automation, reducing manual intervention, enhancing efficiency, and ensuring consistent product quality. E.g., the PLC meticulously regulates liquid metering, filling speed, and sealing time parameters for each capsule. Its reliability minimizes downtime and maintenance costs.

SEW Motor: As the core power component, the high-quality, high-efficiency SEW motor ensures stable, long-term operation, maintaining consistent performance during high-intensity, continuous production. E.g., it provides smooth, reliable high-speed operation crucial for productivity and quality.

Becker Vacuum Pump: The German Becker oil-free dry vacuum pump utilizes advanced technology, eliminating oil contamination risks associated with traditional pumps. This ensures hygienic production and high product quality. The pump's efficiency and reliability are critical for the vacuum system. E.g., during capsule sealing, the pump rapidly evacuates air, ensuring a tight seal and preventing capsule deformation or loose seals due to trapped air.

Conclusion

The NJY 330C Liquid Capsule Filling Machine represents the ideal solution for pharmaceutical and healthcare product manufacturers. Its superior technical advantages—including high flexibility and versatility, intelligent automation, precise control, efficient drying, streamlined maintenance, and strict adherence to international standards—make it an indispensable asset for high-quality production.

IPv6 network supported

IPv6 network supported