When a long holiday approaches, production teams usually focus on final orders, shipment deadlines, and workforce planning. Machines are often shut down quickly once production stops, with the assumption that they can simply be restarted after the break.

In reality, Long holidays are often when hidden machine problems begin — not because the equipment is running, but because it isn’t.

In many packaging and pharmaceutical plants, unexpected failures after a long break are caused not by machine quality, but by improper shutdown and restart procedures.

Machines may remain idle for days or even weeks, exposed to humidity, dust, and temperature fluctuations. Without proper preparation, this idle time can lead to corrosion, contamination, mechanical degradation, and unexpected faults during restart.

Experienced engineers understand one simple principle:

a smooth restart always begins with a correct shutdown.

In today’s article, we’ll show you how to properly shut down packaging and pharmaceutical machines before a long holiday, and how to restart them safely when production resumes, take our workshop as an example.

Once production stops, many teams believe the job is done.

Power off, lock the door, and wait for the holiday to end.

However, as a manufacture, I can tell you that packaging and pharmaceutical machines are not designed to remain idle without preparation.

During normal production, machines operate regularly. Moving parts stay lubricated, surfaces remain dry, and operators can quickly notice abnormal conditions.

During a long holiday shutdown, however:

● Machines stop moving for extended periods

● Factory ventilation and air conditioning may be reduced

● Humidity levels often increase

For precision equipment like tablet press and capsule filling machines, even small environmental changes can have a significant impact. Metal surfaces may oxidize, powder residue can harden, and lubricants may dry out or separate.

Many post-holiday problems—such as abnormal noise, unstable operation, sensor errors, or rusted tooling—are not caused by machine quality, but by insufficient shutdown preparation.

These issues rarely appear immediately.

They often surface only after production restarts — when schedules are tight and problems become costly.

This is why experienced engineers treat long-term shutdown as a controlled process, not a pause.

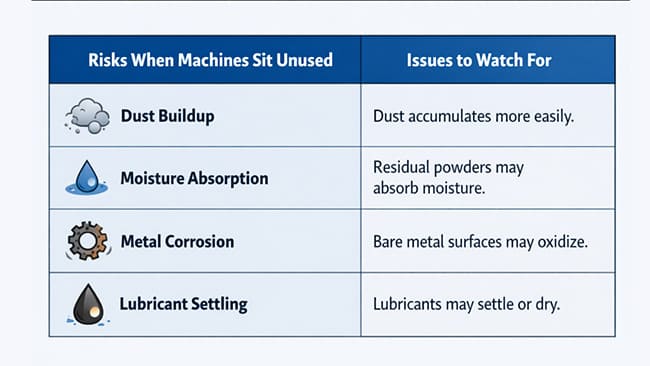

When machines sit unused for days or weeks, several risks quietly build up.

1. Dust accumulates more easily

2. Residual powders may absorb moisture

3. Bare metal surfaces may oxidize

4. Lubricants may settle or dry

Moisture in the air can lead to corrosion on exposed metal parts, especially like filling zones and tooling areas of the capsule filling machine.

Dust and residual product may contaminate sensors, guides, and sealing surfaces.

Belts, bearings, and transmission parts may lose lubrication effectiveness.

In some cases, improper shutdown can even affect alignment or mechanical precision.

These risks apply across different equipment types — including capsule filling machines, tablet presses, blister packing machines, counting & bottling machines, and cartoning machines, stick pack packaging machines.

The longer the idle period, the higher the chance that small issues turn into restart failures.

Experienced maintenance teams follow one simple rule:

A stable restart is always prepared before the shutdown begins.

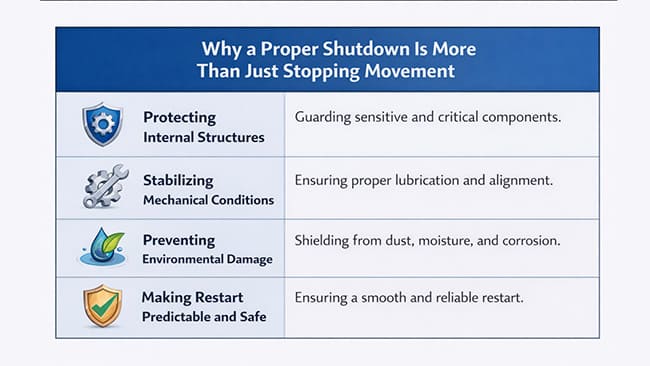

This means shutdown is not just about stopping movement.

It is about:

● protecting internal structures

● stabilizing mechanical conditions

● preventing environmental damage

● making restart predictable and safe

With this mindset, long holidays no longer create uncertainty — they become routine.

Now, please follow my steps.

Before the holiday begins, shutdown should follow a clear and disciplined sequence, not a rushed stop at the end of production.

In our workshop, the first step of any holiday shutdown is the complete disconnection of utilities:

● Electrical power

● Compressed air

● Water supply

This applies to all equipment, including blister packing machines, counting and bottling machines, and cartoning machines, which often rely heavily on pneumatic systems.

This step is not only about safety.

It also prevents pressure buildup, condensation, and accidental activation while the machine remains idle.

After isolation, the machine is allowed to complete its current cycle and return to a neutral mechanical position.

Avoid sudden stops.

Gradual shutdown reduces unnecessary stress on cams, gearboxes, and transmission components. Use the jog button.

Tooling removal is one of the most critical steps—and one of the most frequently overlooked.

Precision tooling used in tablet press machines and capsule filling machines should never remain installed during long shutdowns. These components are highly sensitive to humidity and contamination.

Typical tooling includes:

Tablet press machines:

Upper punches, lower punches, dies, hoppers, and feeders

Capsule filling machines:

Tamping pins, dosing discs, upper and lower segments, and material hoppers

Blister packing machines:

Brush feeders; pre-installed PVC film rolls and aluminum foil rolls may remain on the machine, as long as the exposed outer layers are removed and discarded before production resumes.

● Carefully dismantle tooling according to standard procedures

● Clean all tooling thoroughly to remove powder, oil, and residue

● Dry components completely

● Apply a light layer of anti-rust oil if required

● Store tooling in clean, dry, dedicated tool boxes

Proper storage prevents corrosion, deformation, and accidental damage. It also makes reinstallation faster and more reliable after the holiday.

Leaving tooling on the machine may save time before the holiday, but often results in additional work—and risk—during restart.

【Punches and dies properly stored】

【Punches and dies properly stored】

PS. Cleaning should start right after shutdown, not days later.

Machines such as tablet press machines, capsule filling machines, and counting and bottling machines handle powders, tablets, and capsules daily. Residue inevitably remains in:

● Feeding stations

● Filling stations

● Product contact parts

● Corners, gaps, and guiding rails

If these residues are left on the machine during a long shutdown, they may absorb moisture, harden, or promote corrosion. In pharmaceutical environments, this can also create hygiene risks when production resumes.

After cleaning, all parts must be completely dried. Moisture left on metal surfaces is one of the most common causes of rust during long idle periods.

All exposed metal parts must be protected before the holiday.

This step is especially critical in high-humidity or fluctuating temperature environments.

two types of protection are commonly used:

Anti-rust oil should be applied to:

Exposed metal surfaces

Tooling and non-transmission parts

Areas prone to moisture exposure

Its purpose is to create a protective film that prevents oxidation.

Grease should be applied to:

Bearings

Chains and gears

Transmission and sliding components

Grease helps prevent parts from drying out, seizing, or developing abnormal friction during inactivity.

Correct application is essential. Excessive lubrication may attract dust, while insufficient protection may lead to corrosion.

Finally, the machine is sealed and protected.

Covers are closed, dust protection is applied, and clear tags indicate long-term shutdown status.

At this point, the machine is not simply “off” —

it is preserved and prepared for a controlled restart.

【machinery dust cover】

A long holiday should never be a blind pause.

It should be a controlled and well-prepared stop.

Restarting production after a long holiday should never be rushed.

Most post-holiday issues are not caused by new faults, but by problems that developed quietly during downtime.

The first step is inspection, not operation.

Before restoring power, operators should visually check the machine for moisture, dust, corrosion, loose parts, or abnormal positioning. Any unusual sign is a signal to pause and correct the issue before startup.

Once the machine passes inspection, utilities can be restored in a controlled sequence — electrical power first, by compressed air — and the equipment should then be run empty.

This confirms mechanical stability, sensor response, and motion consistency without putting product or tooling at risk.

Only after a stable empty run should production resume, starting at reduced speed. This allows lubrication to redistribute, tooling to settle, and product quality to be verified before returning to normal operation.

Long holidays don’t have to be a source of uncertainty for packaging and pharmaceutical equipment.

These practices are based on real engineering experience and proven maintenance principles.

With a structured shutdown and a controlled restart, machines remain protected, production stays predictable, and the first day back becomes routine rather than stressful.

Small actions taken before the holiday can prevent major problems afterward.

A good shutdown today leads to a confident, efficient restart tomorrow.

In real manufacturing environments, stability is rarely achieved by doing more —

it comes from doing the right things, at the right time.

With Chinese New Year just around the corner, all of us at Rich Packing in China would like to extend our warmest wishes to friends and partners worldwide.

We wish you a happy New Year, good health, and success in every production run ahead.