Following the successful conclusion of the CPhI Shanghai Exhibition, Rich Packing, a leading enterprise in China's pharmaceutical and packaging machinery industry, will make a appearance at the CPhI Shenzhen Exhibition (8A57, Hall 8) from September 1st to 3rd.

At this exhibition, Rich Packing will launch two star products: the DSL-16R gummy counting and bottling machine specially developed for counting sticky gummies, and the HZP-15/20D intelligent rotary tablet press machine equipped with real-time pressure detection and an intelligent waste rejection system.

Due to their special texture, sticky gummies are prone to problems such as adhesion and inaccurate counting during the counting process. Ordinary counting machines often fail to meet the requirements of efficient and precise production. The DSL-16R candy counting and bottling machine adopts a number of innovative designs to make gummy counting no longer a problem.

♦ Equipped with a Z-type lifting feeder, which realizes preliminary separation and quantitative feeding of gummies at the feeding end.

♦ The gummy candy feeding hopper has a built-in stirring agitator to break up piles of gummies.

♦ According to the size of different gummies, a custom-designed PTFE anti-stacking rollers can be made to ensure that each passing gummy is separated.

♦ The Teflon-coated dimple-shaped counting channel minimizes the contact area between the candy and the counting plate, allowing the candy to slide faster and more smoothly.

♦ The size of the bottle mouth is 159% larger than that of ordinary counting machines, eliminating the blockage of gummies at the outlet.

The 16-channel 16R gummy counting machine with the above designs effectively reduces the sticky adsorption between gummies. It can perform high-speed counting and bottling of various gummies, achieving a maximum output of 80 bottles per minute and a counting accuracy of over 99.97%, providing an efficient and stable solution for candy packaging enterprises.

The pressure stability during the tablet pressing process directly affects key quality parameters such as tablet hardness and disintegration. Traditional tablet presses often suffer from reduced product qualification rates due to pressure fluctuations.

The HZP-15/20D intelligent rotary tablet machine uses high-precision pressure sensors to monitor the pressure of each punch in real time, and synchronously transmits the data to the central control system. When the pressure exceeds the preset range, the system will immediately issue an alarm and start the intelligent waste rejection device to automatically remove unqualified tablets, ensuring that the weight error of tablets in the same batch is within ±2%.

The production speed of this equipment can reach 95,000 tablets per hour, and it can press round, special-shaped, and ring-shaped tablets, etc. When producing different tablet specifications, the mold change time of the entire tablet press is only 8 minutes, widely applicable to the large-scale production of western medicine and traditional Chinese medicine tablets.

In addition, the HZP-15/20D tablet compression machine also has the following advantages:

♦ Residual powder recycling system: Driven by the power of the main turntable, the powder return turntable collects the residual powder into the feeder for secondary use, improving the utilization of raw materials.

♦ Pre-pressing system: Effectively removes air from the medicinal powder in advance, prolongs the effective tableting time of the main pressure wheel, and improves tableting quality.

♦ Intelligent lubrication system: Realizes independent automatic progressive sealed oil supply for the lubrication of molds, guide rails, pressure wheels, and pressure wheel shafts, etc.

♦ Mold overall adjustment system: By moving the positions of the upper and lower main pressure wheels as a whole, the forming position of the tablet in the middle mold is moved, prolonging the service life of the turntable and the dies.

The appearance of these two star products not only demonstrates Rich Packing's continuous investment in technological research and development, but also reflects its product concept oriented to solving customer pain points.

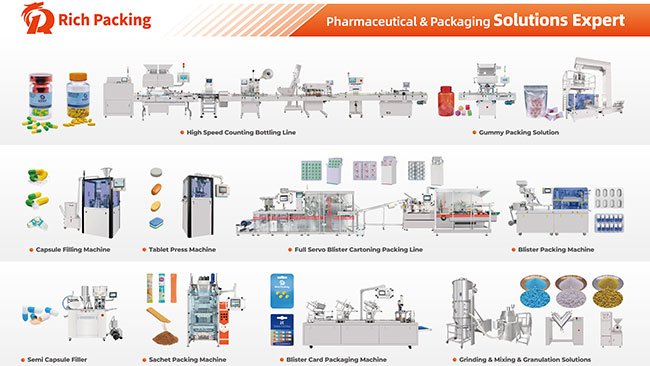

At present, Rich Packing has built a complete industrial chain system covering R&D and design, manufacturing, quality inspection, and after-sales service. Its products cover the whole process equipment for solid preparation production such as capsule filling, tablet pressing, blister packaging, counting packaging, and cartoning. It has passed ISO9001, SA8000 system certifications and multiple international certifications such as CE and RoHS. Its equipment had been exported to more than 80 countries and regions around the world.

At this CPhI Shenzhen Exhibition, Rich Packing will set up an exclusive booth in the core area of the exhibition (Booth: 8A57, Hall 8) to conduct in-depth exchanges with visiting customers on technical issues and solutions in pharmaceutical production. Whether you are seeking efficient production equipment upgrades or exploring intelligent pharmaceutical factories, Rich Packing's professional team will provide you with tailor-made solutions.