HZP-15/20D Rotary Tablet Press Machine

*** Technical parameter

|

Model |

HZP-15/20D |

|

Max. Production Capacity |

95000 pcs/h |

|

Max. Pressure |

100 kN |

|

Pre Pressure |

12 kN |

|

Max. Dia. of Tablet |

25mm |

|

Max. Thickness of Tablet |

10mm |

|

Rotary Speed |

10-110 r/min |

|

Motor |

4.5kw |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Introduction to the Intelligent Rotary Tablet Press

The Rich Packing HZP-15/20D Intelligent Rotary Tablet Press Pharmaceutical represents the seventh generation of fully automatic high-speed tablet presses, featuring a maximum tablet diameter of 25mm, a maximum tablet thickness of 10mm, and a maximum output of 95,000 tablets per hour. It is ideally suited for pharmaceutical companies, healthcare product manufacturers, food producers, and other enterprises with small to medium production needs, particularly those with stringent requirements for tablet weight accuracy.

The press's high-efficiency production capacity and precise tablet weight control enable it to meet rigorous pharmaceutical quality standards, ensuring drug stability and safety. For healthcare product manufacturers, the equipment guarantees product uniformity and consistency, enhancing market competitiveness. In food production, it is suitable for scenarios requiring the compression of powders or granules into tablets. The intelligent design and high-precision control system allow the press to adapt to diverse production requirements, delivering efficient and reliable tableting solutions.

Advantages of the HZP-15/20D Rotary Tablet Press

Tablet Pressing Capacity and Efficiency

The Rich Packing HZP-15/20D intelligent rotary tablet press excels in pressing capacity and efficiency, meeting the high-output demands of small and medium-scale production. With a maximum tablet diameter of 25mm and a maximum thickness of 10mm, the equipment accommodates tablets of various specifications, including standard round tablets and special-shaped tablets, with precision.

Notably, the press achieves a maximum output of 95,000 tablets per hour, a capability driven by its Siemens main motor. The turntable operates at a maximum speed of 110 revolutions per minute, ensuring high efficiency and uninterrupted production.

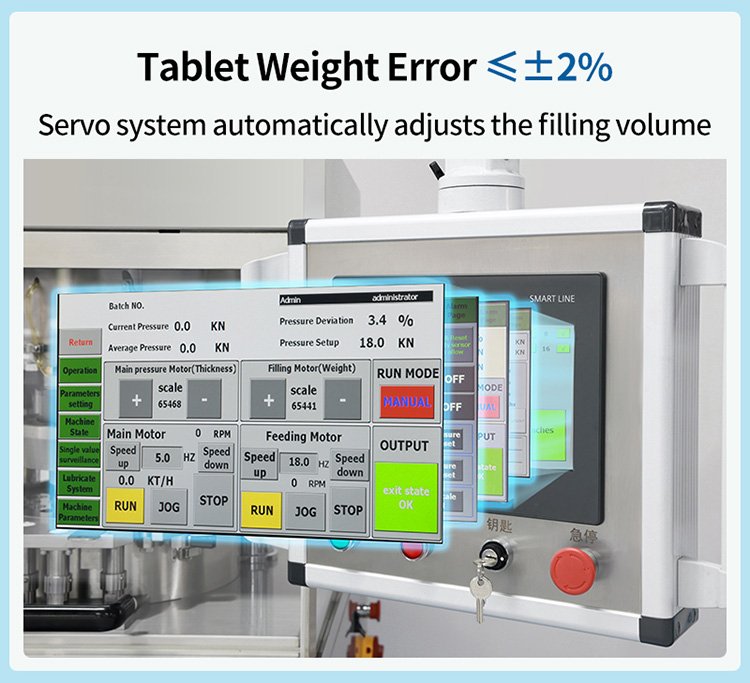

Tablet Weight Adjustment and Accuracy

The Rich Packing HZP-15/20D automatic rotary tablet press stands out in weight adjustment accuracy, leveraging advanced technology for superior performance. Unlike traditional handwheel adjustment systems, this press employs a servo motor to precisely control the filling track, automatically adjusting the filling volume based on preset values.

Test results demonstrate that the average tablet weight accuracy is consistently maintained within ≤±2%, a leading industry standard. This precision ensures uniform tablet weights, critical for pharmaceutical production and other applications with strict weight tolerance requirements.

Additionally, the press features a secondary forced feeding system combining metering and feeding stirring. This innovative design prevents material stratification, further enhancing weight stability. By ensuring each tablet meets precise weight standards, the system improves product qualification rates, reduces production costs, and delivers greater economic benefits and quality assurance.

Tablet Press Design and Structure

The Rich Packing HZP-15/20D pharmaceutical tablet press incorporates innovative design elements in its guide rails and molds, ensuring operational efficiency and product quality.

Double-Sided Clamping Guide Rail Design:

The press utilizes a double-sided clamping guide rail that securely supports molds from both sides, enhancing stability during high-speed operation. Compared to traditional single-sided support rails, this design minimizes mold vibration and deviation, improving tablet forming accuracy and consistency.

In practical operation, the mold can achieve speeds of up to 110 revolutions per minute while maintaining low noise levels, outperforming comparable industry products.

Feeding System and Stability

The feeding system's stability is crucial for tablet quality and production efficiency. The Rich Packing HZP-15/20D medicine tablet press integrates advanced technologies to ensure uniform and stable feeding.

Secondary Forced Feeding Method:

The press employs a secondary forced feeding system with metering and feeding stirring, effectively preventing material stratification during the feeding process. Stratification can lead to uneven tablet weights and compromised product quality. The forced feeding mechanism ensures consistent material distribution into the molds, enhancing weight stability. Test data indicate a tablet weight standard error of ±0.2g with this system.

Intelligent Monitoring and Adjustment:

The feeding system is integrated with the press's intelligent control system, enabling real-time monitoring of material flow and filling volume. If deviations from preset values occur, the system automatically adjusts to maintain feeding continuity and stability. This intelligent functionality not only improves system reliability but also optimizes feeding parameters based on material characteristics and production requirements, boosting efficiency and automation.

Pre-Pressing System Support:

The pre-pressing system plays a vital role by removing air from the middle mold and powder, improving powder plasticity for the main pressing stage. This system enhances tablet quality and extends the main pressing wheel's operational time, increasing overall efficiency. In production, the pre-pressing system improves tablet hardness uniformity by approximately 20%, significantly elevating product quality.

The press also features real-time counting of finished and defective products, with customizable pressure limits for individual molds based on material properties. If pressure or weight exceeds set thresholds, the system triggers an alarm and shuts down automatically. This intelligent monitoring reduces manual intervention, minimizes operator workload and errors, and enhances overall efficiency.

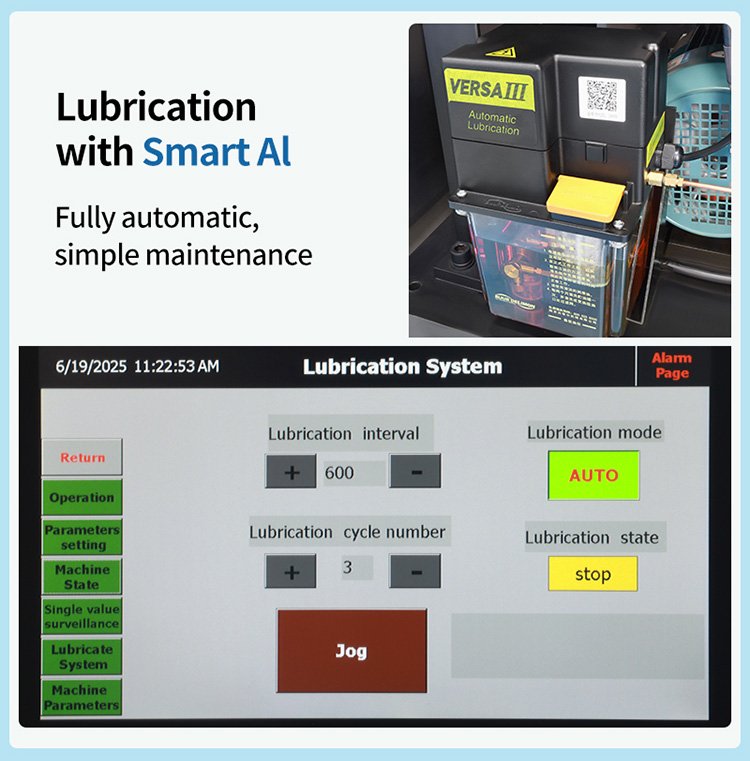

Lubrication System and Durability

The Rich Packing HZP-15/20D intelligent rotary tablet press incorporates an advanced lubrication system, enhancing durability and operational stability.

Intelligent Lubrication System:

The press features an intelligent lubrication system with independent automatic progressive sealed oil supply for both liquid and solid lubricants. Liquid lubricants are applied to molds and guide rails for smooth high-speed operation, while solid lubricants protect pressure wheels and toothed shafts from friction-induced wear. The system dynamically adjusts lubricant volume based on operational conditions for optimal performance.

Enhanced Durability:

The pressure wheel in HZP tablet press machine is constructed from alloy tool steel, which is harder than the mold material, and is sealed to prevent dust ingress. This design significantly improves wear resistance and extends service life. Practical data show that after producing 10 million tablets, the wear on alloy tool steel pressure wheels is only 10% of that on traditional wheels, ensuring long-term stability.

Reduced Maintenance Costs:

The intelligent lubrication system lowers maintenance frequency and costs. Unlike traditional presses requiring manual lubrication, this system automates the process, reducing labor and resource expenditure. Statistics indicate a 30% reduction in maintenance costs, delivering substantial savings.

Conclusion

The Rich Packing HZP-15/20D intelligent rotary tablet press machine is an ideal solution for small and medium-scale production, offering exceptional performance in pressing capacity, weight accuracy, design, feeding stability, intelligent functions, safety, and material durability. Its innovative features and reliable operation make it a standout choice for industries requiring high-quality tableting solutions.

IPv6 network supported

IPv6 network supported