Premade Pouch Packing Machine

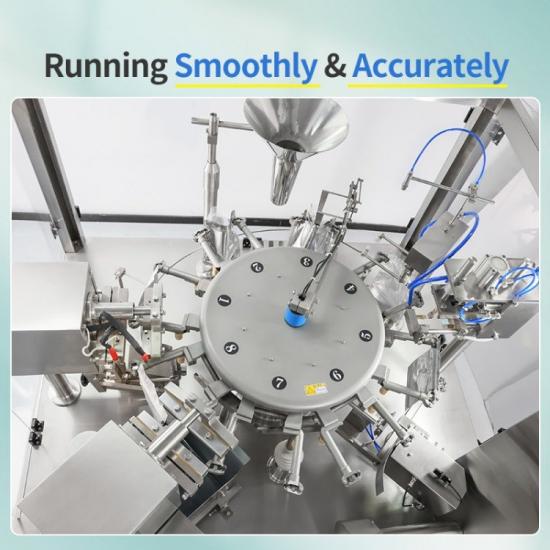

Our premade pouch packing machine's advantages includes

High Configuration and Strong Stability: All electronic components in this pouch packaging machine are from world top international brands in Germany, Italy and Japan, ensuring reliable and stability.

Wide Applicability: Suitable for packaging a variety of materials into pre-made sachet, with the materials including gummies, nuts, powders, , granules, pellet, sachets, and liquid pulps. The solution is to replace the filling mechanism according to customer requirements (as counting machines, multi-head weighers, powder feeders, pulp injection pumps, etc.).

Servo Motors for Bag Picking: The pouch picking mechanism driven by servo motors can make sure accurate pouch movement and prevents multiple bags from being picked at each time.

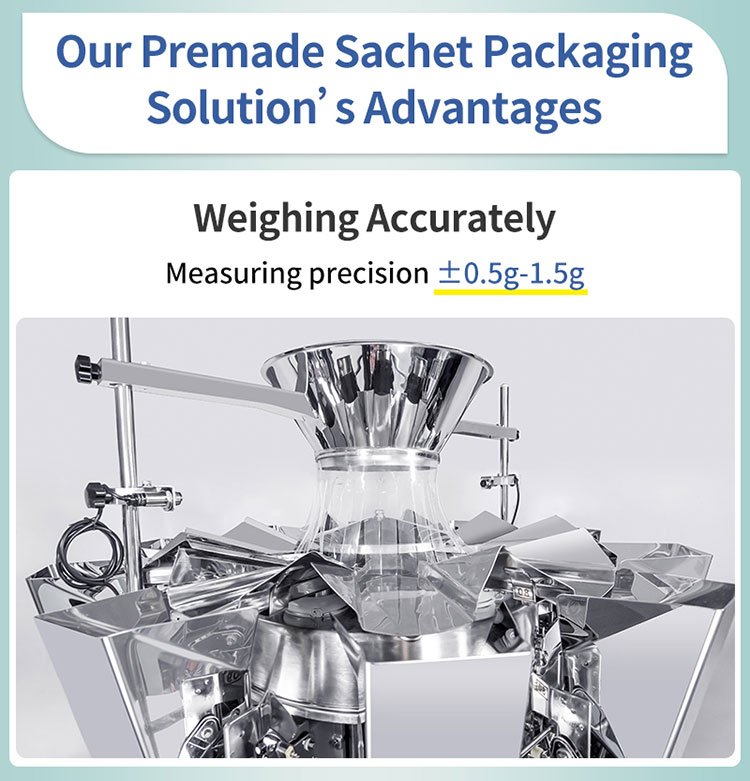

High Packing Precision: Automatic counting and filling achieve a precision of 99.98%, with multi-head electronic combination weigher offering a weighing precision of ±0.40%-1.0%.

Waste Rejection and Strong Exhaust: Can rejects materials of weights that exceed the weight error range automatically .

High Automation to Saving Labor and Costs: From bag picking, material filling to shaping, netting, and discharging, fully automated and requiring no manual intervention.

Easy Pouch Type Change with One-Click Adjustment: The bag width adjustment is automatically completed by the motor, allowing bag change in 2 minutes.

Equipped with German Becker oil-free vacuum pumps, Staying Environmentally Friendly: the machine operates stably with noise below 65DB, significantly reducing impact on the working environment.

Abnormal Shutdown Protection: The sachet packaging machine series is equipped with a protection function for abnormal shutdowns due to compressed air and vacuum negative pressure issues.

Excellent Operational Performance for 24/7 Production: Our company's multi head weigher pouch packaging machine is suitable for continuous 24-hour production.

| Models | PMG-200H | PMG-260H | PMG-300H | PMG-360H |

| Max Speed | 60 pouches/min | 50 pouches/min | 50 pouches/min | 50 pouches/min |

| Power | 3.5 kW | 4.5 kW | ||

| Voltage | 220V / 380V / 50Hz,customizable | |||

| Material Requirements | PE, PET, PP composite plastic films | |||

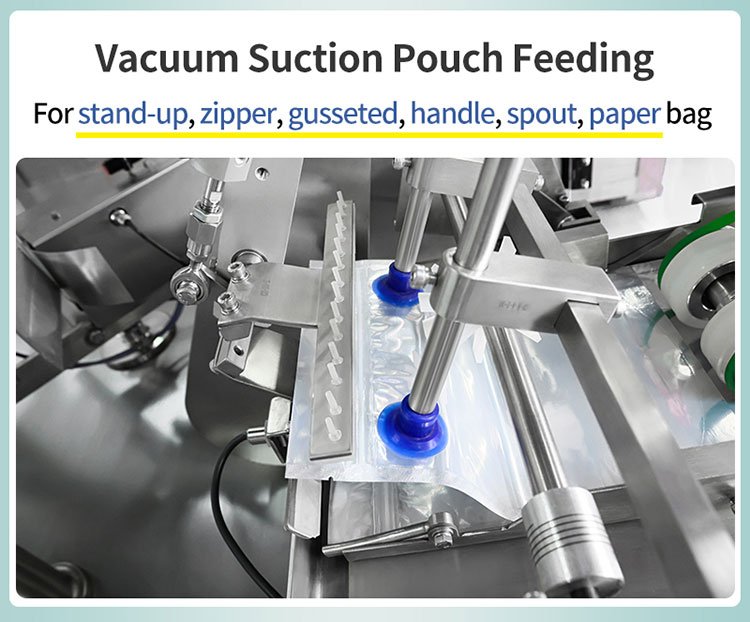

| Applicable Bag Types | 3/4 side seal, back seal, stand-up pouches, zipper pouches, etc. | |||

| Bag Sizes | L: 90-360mm W: 100-220mm | L: 150-360mm W: 150-270mm | L: 190-460mm W: 200-310mm | L: 260-510mm W: 250-360mm |

IPv6 network supported

IPv6 network supported