How are tablets made? Manufacturing tablets is a complex process of transforming active pharmaceutical ingredients (API in the form of powder or granules) and excipients into a solid, precise oral dosage form. The core goal is to ensure pharmaceutical tablets contain the same amount of tablet composition.

This tablet manufacturing process typically involves key steps like granulation where fine powders are processed into larger and flowable granules to ensure uniformity, and tablet compression where these granules are pressed into their final tablet form between two punches under high pressure. This meticulous tablet manufacturing procedure guarantees dosage accuracy, stability, and efficacy.

tablets and punches that press pharmaceutical ingredients into tablets

The science of tablet production is driven by a set of critical, non-negotiable objectives which ensure final medication tablets are not only effective but also safe and reliable.

●Uniformity of Drug Tablets: Every batch of pharmaceutical tablets must have a consistent formulation, meaning each individual pill or tablet is identical in its diameter, thickness, and weight, since this physical consistency is the foundation of dose accuracy, ensuring patients receive the correct amount of tablet ingredient every time.

●Medicine Tablet Safety & Efficacy: Medicine tablets must be bioavailable, with all tablet ingredients being non-toxic, made for human body to absorb the pharmaceutical ingredient effectively.

●Physical Stability: Drug tablets must be hard and compact enough to withstand the impact during pill manufacturing, tablet coating, pharmaceutical packaging, and global shipping without chipping or breaking. Conversely, pills and tablets must not be so hard that they fail to disintegrate within the gastrointestinal tract.

●Chemical Stability: The medicine tablet formulation must remain chemically unchanged over pill shelf life, protected from degradation by factors such as moisture, light, and oxygenation, to guarantee the therapeutic effect.

●Finished Tablet Quality: Medication tablets should have a smooth, polished surface, often achieved by using a tablet polishing machine that integrates functions of a tablet deduster and a metal detector, which removes residual dust on tablets and enhances product appearance.

●Drug Release Design: Drug tablets must be designed to disintegrate and dissolve at the correct rate and location in the digestive tract to release tablet ingredients for absorption, whether it's an immediate, delayed, or extended drug release.

The pharmaceutical manufacturing process of producing tablets involves precision and complexity. The choice of tablet manufacturing techniques is critical to make pills and depends on properties of API and excipients. The three primary techniques involved in addressing how pills are made are dry granulation, wet granulation, and direct tablet compression.

granules

Dry granulation does not rely on liquid binders. Instead, it directly compacts and shapes powder through physical force, ultimately turning powder into granules with certain strength and particle sizes. The core advantage of dry granulating method is that it avoids the "liquid addition and drying" process involved in traditional wet granulation.

dry granulation process

●When Is Dry Granulation Suitable?

Dry granulation is ideally used under following circumstances:

◌API is highly sensitive to moisture or heat.

◌The powder blend has adequate inherent flowability and compression properties but needs densification to ensure uniform content.

●Specific Processing Steps of Dry Granulation

The dry granulation process typically involves two key steps:

Mixing → Compression into Sheets/Strips → Crushing & Sizing → Screening & Product Output

1) Mixing: Thoroughly mix the pharmaceutical ingredient drug or raw material powder with excipients, fillers, or disintegrants in a mixer.

2) Compression into Sheets or Strips: Use a roller compactor to form large sheet-like, strip-like, or block-shaped dry compacts.

3) Crushing and Sizing: Break dry compacts and then size them through screening to obtain granules within the desired particle size range.

4) Screening and Finished Product Output: Screen according to particle size requirements; the qualified tablet granules are the finished product.

Typically in the field of pharmaceutical processing, the final granule blend is fed into a pill press tablet press machine for compression into medication tablets in a way to carry out tablet manufacturing.

Wet granulation, compared to dry granulation, is a more widely used granulating method, involving the addition of a liquid binder, or called as granulating solution, to medical powder mixture. Specifically, the liquid binder acts as an adhesive, causing pharmaceutical powder particles to agglomerate into tablet granules when agitated.

wet granulation process

●When Is Wet Granulation Suitable?

Wet granulating process is the preferred choice when:

○The pharmaceutical ingredient is stable in the presence of the chosen granulating liquid.

○The primary drug powder blend has poor flow properties and needs to be converted into dense, free-flowing tablet granules.

○The medication powder has low compressibility and requires the binding action to form strong, robust pharmaceutical tablets.

●Specific Processing Steps of Wet Granulation

The wet granulation process follows a sequential flow:

Mixing (Premixing) → Adding Liquid Granulating Binder → Wet Massing → Granulation → Drying → Particle Sizing

1) Weighing and Mixing: Active Pharmaceutical Ingredient and excipients are accurately weighed and mixed uniformly in a mixer.

2) Addition of Binder Solution: The granulating liquid (binder in solution) is added to medication powder mixture while agitation continues.

3) Wet Massing: Mixing continues until a desired wet mass with a specific consistency is achieved.

4) Wet Sieving (Granulation): The wet mass is forced through a sieve to break down large lumps and initiate granule formation.

5) Drying: Wet granules are transferred to a dryer, such as a tray dryer or a fluid bed dryer, to remove added liquid.

6) Dry Sieving (Particle Sizing): Dried granules are milled and sieved to break aggregates and achieve a uniform granule size distribution.

Before final dry granules are fed into a tablet press pill press machine, they are blended with extra-granular excipients, primarily a lubricant, to ensure smooth ejection from dies of a rotary tablet press machine, after which the final granule blend is compressed into pharmaceutical pills and tablets, completing the tablet manufacturing process.

In terms of advantages of the two granulating methods, dry granulation and wet granulation respectively own benefits. Overall, dry granulation enjoys less granulating processes and lower cost, while wet granulation enjoys enhanced quality of finished granules.

|

|

Dry Granulation |

Wet Granulation |

|

No Moisture |

√ |

|

|

Skipping Drying Step |

√ |

|

|

Lower Energy Consumption |

√ |

|

|

Less Process Time |

√ |

|

|

Less Equipment |

√ |

|

|

Lower Cost |

√ |

|

|

Denser Granules |

|

√ |

|

Higher Flowability |

|

√ |

|

Higher Compression Plasticity |

|

√ |

|

Granule Content Uniformity |

|

√ |

|

Enhanced Tablet Strength |

|

√ |

From the above list, we can see respective benefits that the two granulating methods possess.

granulation machines

1) Advantages of Dry Granulation

●No Moisture Involved: Eliminates the risk of stability issues caused by water or solvents, ideal for hygroscopic or moisture-degradable compounds.

●No Drying Step: The process is shorter, requires less equipment, and consumes less energy since the lengthy drying phase in a fluid bed dryer or an oven is omitted.

●Cost-Effective: Lower operational costs due to reduced process time and no need for solvent recovery systems.

2) Advantages of Wet Granulation

●Improved Granule Properties: Produces denser, stronger granules with excellent flowability and compression characteristics.

●Higher Content Uniformity: The liquid binding step is effective in distributing the API evenly throughout the granule mass, preventing material segregation.

●Enhanced Tablet Strength: Often results in harder medicine tablets with lower friability, less prone to pill chipping or tablet breaking.

Direct compression is a simplified tablet manufacturing process where tablet material, typically a blended powder mixture of the API and specially designed excipients, is compressed directly into drug tablets without any preliminary granulation processes.

This way of tablet production has process efficiency. It is the most economical and fastest pill manufacturing method as it eliminates the entire tablet manufacturing steps including granulation, drying, and milling, reducing processing time, equipment needs, and energy consumption. Additionally, this tablet manufacturing procedure is ideal for tablet ingredients sensitive to heat and moisture, as it avoids exposure to both. Moreover, a simpler tablet manufacturing process means fewer steps where things go wrong, bringing about fewer variables during pharmaceutical manufacturing process.

HZP 26D-40D Tablet Press: high-speed tablet pressing process

●Specific Process Steps of Direct Tableting

While simpler, direct compression requires highly optimized tablet manufacturing steps:

Milling → Blending → Tablet Pressing

1) Milling: Pharmaceutical tablet ingredients and excipients are individually milled and sieved to ensure a uniform particle size distribution, critical for preventing tablet material segregation.

2) Blending: Tablet ingredients are mixed with direct compression-grade excipients, including fillers, disintegrants, and lubricants, in a blender until a homogeneous mixture is achieved.

3) Tablet Pressing: The blended medicine powder is fed directly into a tablet manufacturing machine and processed into compressed tablets. This pill tablet press machine must be equipped with features like forced feeders to ensure consistent powder flow and fill of dies.

The pharmaceutical manufacturing process of medication tablets requires specialized equipment to transform raw tablet material into precise dosage forms.

●Size Reduction Machines

Their primary function is to reduce the particle size of raw tablet materials, breaking down bulk materials into smaller particles, tablet granules, or powders. The machinery includes pulverizers, grinders, cutters, and fine grinders.

●Granulation Machines

Granulation machines, such as wet granulating machines, dry granulators, melting granulation machines, and spray drying granulators, convert fine powders into larger, free-flowing granules. This process improves powder flowability and prevents ingredient separation during subsequent tableting stages.

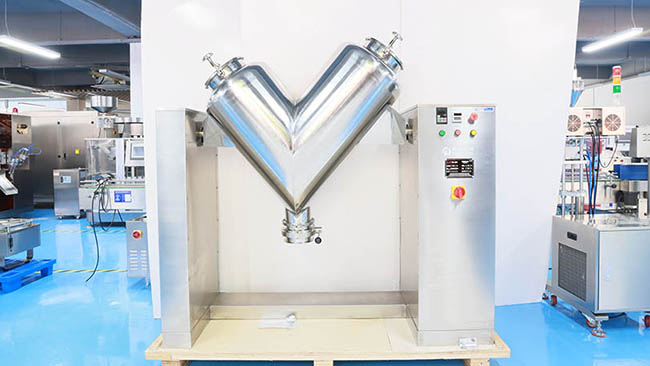

●Mixing Machines

Mixing machines, such as tumble blenders, V-cone blenders, pneumatic mixers, convective mixers, and 3D mixers, are then employed to achieve a perfectly homogeneous blend of the active pharmaceutical ingredients and excipients, guaranteeing dose uniformity during pill manufacturing.

a V-shaped mixing machine

●Drying Machines

Wet granules from granulation must be dried, and this task is handled by drying equipment such as rotary driers and spray driers. Fluidized bed dryers are commonly used, using heated air to efficiently remove moisture, leaving behind dry, robust tablet granules ready for tablet pressing.

●Automatic Rotary Tablet Press

How to make pills? The core equipment of manufacturing tablets is an auto rotary tablet press machine. High-speed rotary tablet presses use mechanical force to compress drug powder or granule blend into solid medical pills of precise shapes, sizes, and hardness between two punches and a die. Pill presses are mainly classified into high-speed tablet presses and medium-to-low-speed tablet presses.

the main mechanism of a high-speed tablet press machine

●Coating Machines

Finally, tablet coating and polishing machines apply a thin film coating to pills and tablets. Perforated pans spray coatings to mask bitter taste, improve swallowability, control drug release, or protect drug ingredient. Polishing drums then impart a desirable aesthetic shine to finished, coated tablets.

This pill coating step is performed after pill making for several key reasons. Primarily, coated tablets mask unpleasant taste or odor, making medication tablets easier to swallow. In addition, coatings also protect active pharmaceutical ingredient from degradation by light, moisture, or air, thereby enhancing medicine tablet stability and shelf-life. Furthermore, specialized coatings can control the drug release profile, enabling delayed or sustained action within the digestive system. Besides, coatings provide a smooth, polished finish that aids in brand identification and improves patient compliance.

The intricate processes of tablet manufacturing, from granulation to tablet pressing, are all meticulously designed to achieve core objectives: ensuring dosage uniformity, stability, efficacy, and controlled drug release. The sophisticated tablet manufacturing machinery employed is fundamental to producing high-quality, reliable tablets that meet stringent pharmaceutical standards.