Tablet press machine suppliers abound in different regions across the globe. This article analyses corporate qualifications of top 10 pill pressing machine manufacturers and their machines’ stand-out features, rendering reliable selections before you procure your tablet pill presses.

Standards and regulations of pharmaceutical industry have become increasingly more stringent. Regulatory agencies like FDA and EMA require more continuous post-market surveillance, and their focuses have shifted from just pre-approval clinical trials to monitoring a drug's safety throughout its entire life cycle. To make sure medication processing machines meet high-standard regulatory compliance, it is significant to select an outstanding manufacturer from hundreds of tablet pressing machine suppliers.

main mechanism of an auto tablet presser and pharmaceutical tablets

A tablet pill press is the equipment utilized in the pharmaceutical, nutraceutical, food, and chemical industries to compress powders or granules into solid pills and tablets of specific sizes, shapes, and weights. The primary function of an automatic pill press is to ensure dosage accuracy and production efficiency on a massive scale.

A pill pressing machine operates on a simple yet engineered principle. At the beginning, powdered ingredient is fed from a hopper into dies with cavities that determine tablet sizes and shapes. Then two punches—an upper punch and a lower punch—move in a coordinated motion to compress powder or granules within a die. This tablet compression process consolidates the ingredient, forming solid pharmaceutical tablets.

|

Manufacturer |

Foundation Year |

Headquarters |

|

Fette |

1948 |

Germany |

|

IMA |

1961 |

Italy |

|

Rich Packing |

1993 |

China |

|

Syntegon |

1969 |

Germany |

|

KORSCH |

1972 |

Germany |

|

Romaco |

1989 |

Germany |

|

GEA |

1881 |

Germany |

|

ACG |

1961 |

India |

|

Natoli |

1973 |

US |

|

Cadmach |

1994 |

India |

Headquarters: Germany

Founded in: 1948

Fette Compacting is a global leader in pharmaceutical tablet compression technology, supplying high-performance rotary and single-punch pill pressing machines for nutraceutical and medication tablets. Founded as a specialist engineering firm, Fette focuses on precision and scalable pharmaceutical production solutions with a strong global service network.

Strengths:

●World-class engineering and equipment construction quality.

●Focus on cGMP compliance, machine cleanability and operator safety.

●Broad portfolio from R&D of equipment functions to high-speed production of solid preparation (e.g. pills and capsules).

●Strong after-sales service, user training and spare-parts support.

Standout Features of Their Pill Pressing Machines:

●High-speed rotary designs with stable tablet weight control and low rates of unqualified tablet rejection.

●Modular-designed mechanisms for quick tablet press tooling changeover, and multi-layer tablet or tablet-in-tab production.

●Pill press automation and tablet compression process monitoring (data logging, SPC, OEE).

●Robust containment and isolation options for potent APIs.

Headquarters: Italy

Founded in: 1961

IMA S.P.A. is a global leader in automatic machines for processing and packaging across pharmaceuticals, cosmetics, food and beverage, with 40+ production sites and a broad international sales and service network.

Strengths:

●Experience across the full pharmaceutical value chain including equipment R&D, pilot production line operation, and high-volume production.

●Expansive global footprint and strong after-sales service capability for fast support.

●Broad portfolio via specialized divisions (IMA Pharma / IMA Active), enabling turnkey pharma packaging line solutions.

Standout Features of Their Pill Presser Machines:

●PREXIMA Family: Modular pill presser models from small-batch to high-throughput tablet production with tooling change flexibility.

●Robust Mechanical Design for high compression force and repeatable pill quality.

●cGMP-oriented layout for fast cleaning, pressing tablet mold changeover and containment options for sensitive APIs.

Headquarter: China

Founded in 1993

As a leading force in China's pharmaceutical equipment sector, Rich Packing combines machinery design, production, and development, focusing on manufacturing pharmaceutical processing and packaging machines, and integrated package lines for a worldwide clientele in US, Europe, South America, and Asia. With an annual capacity of 280 tablet pressers, they supply fully automatic pill pressing machines with max output ranging from 9,000 to 960,000 tablets/hour. This manufacturer continuously pursue technological innovation, backed by 30+ years of overseas service experience. Their reputation is confirmed by successful collaborations with globally renowned companies such as INOV Pharma, US Pharma, and Robinson Pharma. For example, they provided INOV Pharma with an ZP27D tablet pill press delivering tablet weight consistency and different ingredient handling capability. All of our machines are only for Pharmaceutical, Nutraceutical, Food. The purchase of tablet press machine and capsule filling machine must comply with the laws and regulations of your country. For example, according to regulatory requirements, importing these machines into the United States requires DEA approval.

Strengths:

●Focuses in manufacturing pharmaceutical machinery, including capsule filler filling machines, automatic pill compressors, blister packing machines, pill capsule counting machine lines, etc., designed for large-scale production and packing of medication.

●All-round services include remote or in-person operator training, 3-year warranty and 1-year free spare part replacement, and global on-site machine installation, commissioning and maintenance, etc.

●Integrates tablet capsule and food packaging lines with customization capability. Machines are tailored based on users’ product specifications, work space, and budgets.

Standout Features of Their Pill Presser Machines:

●Regulatory Compliance: Designed for meeting standards of cGMP, EMA, and FDA 21 CFR Part 11, their high speed rotary tablet presses such as HGZP26D have progressive functions of access security, audit trail, and e-signature.

●Tablet Uniformity Management: For maintaining consistent tablet weight and hardness, their pill tablet press machines employ precisely machined tooling, forced feeders, real-time pressure monitoring systems, automatic fill volume controls, single-piece waste rejection, and pre-compression systems.

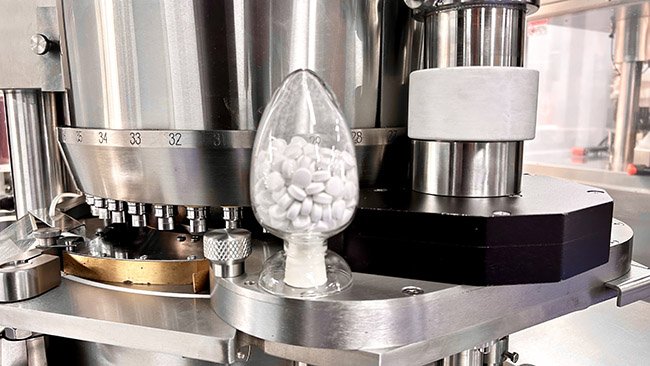

●Fast Tooling Changeover: Accomplished through modular design of components such as feed hoppers, forced feeders, dies, punches, etc. Tool-free die change is feasible thanks to high-precision grinding of each turret and die hole (e.g. HGZP17D rotary tablet press).

●Easy Maintenance: For convenient cleaning and maintenance, pill press operating platforms adopt a large-platform and dead-angle-free design, and intelligent lubrication systems are equipped in their pill press machines.

tool-free mold changeover

Headquarters: Germany

Founded in 1969

Syntegon is a global technology company specializing in processing and packaging solutions for pharmaceutical, biotech and food industries. The company employs several thousand professionals across more than 20 countries.

Strengths:

●Broad sector experience across food and pharma, enabling cross-domain know-how and synergy.

●Global service and lifecycle support network, helping customers with uptime, maintenance and continuous pharmaceutical production optimization.

●Strong R&D and patent portfolio, underpinned by more than 2,000 patents/applications.

Standout Features of Their Press Tablet Machines:

●High Output Capacities: For example, TPR 700 tablet press machine can produce more than a million drug tablets per hour.

●Fast mold Changeover: The turret removal design allows rapid product changeovers (sometimes under an hour), and facilitates multi-layer or varied tablet forms.

●Hygienic, Compact, Easy-to-clean Design: Pill tablet presses are built for meeting cGMP environmental requirements.

●Modular Powder Feeding Systems: The two- or three-paddle feeder design improves flowability for challenging powders, helping ensure consistent powdery ingredient fill volume and tablet weight even for some tricky protein powders.

Headquarters: Germany

Founded in 1919

KORSCH AG is a global leader specializing exclusively in tablet making technology and machinery for pharmaceutical, nutraceutical, and chemical industries.

Strengths:

●Over a century of machine engineering expertise and innovation.

●Global service network and dedicated technical support.

●Strong focus on equipment research, solution customization, and continuous process improvement.

Standout Features of Their Pill Press Machines:

●Precision and reliability through advanced tablet quality control and real-time detection systems.

●Flexible design enabling rapid tooling changeovers and multi-layer tablet production.

●Robust machine construction ensuring consistent performance of tablet compression in high-volume operations.

●Integrated tablet compression and packaging data tracing and automation systems supporting Industry 4.0 compliance.

●User-friendly interfaces with intuitive HMI for optimized digital control of automatic pill pressing.

Headquarters: Germany

Founded in 1989

Romaco Group is globally a leading supplier of machinery for pharmaceutical and nutraceutical processing and packaging. They operate a network of specialized brands and production facilities, offering integrated solutions that cover the entire value chain—from powder processing to final dietary supplement or medication tablet packaging.

Strengths:

●Manufacturing portfolio covering multiple stages of medication/supplement production and packaging.

●Strong engineering expertise and German precision manufacturing.

●Global customer service network ensuring fast support and spare parts supply.

Standout Features of Their Pill Pressing Machines:

●Precision and consistency: Intelligent tablet pressing technology ensures uniform tablet weight and pill hardness, ideal for pharmaceutical-grade quality.

●Flexibility: Modular designs allow quick mold changeovers between different tablet sizes and shapes, boosting tablet production efficiency.

●User-friendly Operation: Intuitive interfaces and automated controls simplify pills press setup and tablet pressing monitoring.

●Durability: Built with robust materials and tested for long-term continuous pill compression operations.

●Compliance and Safety: Aligned with cGMP standards, ensuring pill tablet integrity and operator safety.

Headquarters: Germany

Founded in 1881

GEA Group is a leading specialist in processing technology and equipment for food, pharmaceutical, and chemical industries. The company has evolved into one of the world’s largest suppliers of processing solutions, with operations in over 60 countries.

Strengths:

●Global Expertise: Extensive international presence with strong engineering capability and after-sales support.

●Innovation Leadership: Continuous R&D investment focusing on equipment durability and digitalization.

●Sustainability: Designs equipment that reduces energy waste in production.

Standout Features of GEA Tablet Press Machines:

●Precision and Consistency: MODUL™ and PERFORMA™ series ensure uniform tablet weight and hardness through advanced tablet conformity control.

●Exchangeable Compression Modules (ECM): Unique to GEA, allowing fast tooling changeovers and eliminating cross-contamination risks.

●Hygienic Design: Tablet press machines meet cGMP and FDA standards, ideal for pharmaceutical manufacturing environments.

●Intelligent Automation: Integrated sensors and smart software enable real-time tablet pressing monitoring, predictive maintenance, and process optimization.

Headquarters: India

Founded in 1961

ACG is a global provider of integrated solutions to the pharmaceutical industry, and they serve customers in more than 100 countries with a wide product portfolio covering hard gelatin capsule shells, press pills machines, tablet packaging lines, inspection and end-of-line systems.

Strengths:

●Broad Global Footprint: Presence across six continents and 100+ countries.

●Integrated Offering: From formulation tools to pharmaceutical packaging and inspection, enabling customers to source their capsule tablet manufacturing chain from one partner.

●Innovation-driven: Adoption of digital and IIoT tools to uphold manufacturing efficiency and regulatory compliance.

Standout Features of Their Tablet Compression Machines:

●Downtime Reduction: Toolless turret changeovers within 30 minutes and fault detection systems (e.g., punch fault detection) help minimize unplanned pill press stoppage.

●Consistent Quality: Sophisticated feeders and waste rejection mechanisms ensure uniform tablet weight, thickness and hardness, critical for regulatory consistency.

●Wide Formulation Capability: Automated tablet machines handle challenging substances including poor-flow powder, and support large-diameter tablet compression.

●Smart Manufacturing Readiness: ACG’s USER platforms (e.g., UltraHMI, ExploreAR, RevealiOT) ensure their tablet pill making machines are ready for digital connectivity, real-time diagnostics, and operator-friendly control.

Headquarters: United States

Founded in 1973

Natoli Engineering is a global manufacturer specializing in producing compression tablet machines, machine tooling, and equipment for pharmaceutical, nutraceutical, and confectionery sectors. Natoli is recognized for its precision engineering, machine innovation, and quality manufacturing.

Strengths:

●In-house design and manufacturing ensures precision and consistency.

●Comprehensive customer support, training, and tooling maintenance services.

Standout Features of Natoli Tablet Compressors:

●Precision Engineering: Designed for optimal tablet compression accuracy, minimizing waste and ensuring consistent tablet quality.

●Durability: Built with components that withstand strict tablet production demands and extend machine lifespan.

●User-Friendly Interface: Human-machine interaction systems simplify operation, calibration, and data tracking.

●Customization: Medicine tablet machines can be tailored to users’ specific production needs, from R&D to high-volume tablet manufacturing.

Headquarters: India

Founded in: 1994

Cadmach Machinery is a leading Indian manufacturer specializing in making pharmaceutical machinery, particularly automatic pill presses. They serve both small and large pharmaceutical companies worldwide.

Strengths:

●Strong R&D capabilities leading to continuous innovation.

●Extensive service network and technical support.

●Proven expertise in precision engineering and compliance with global pharma regulations.

Standout Features of Their Pill Machine Presses:

●Automation and stable construction for consistent tablet quality.

●High output of finished medication tablets with reduced maintenance frequency.

●Flexible tooling design compatible with various tablet sizes and formulations.

●Integrated safety and control systems enhancing reliability.

A high-performance tablet press machine is crucial for mass production in pharmaceutical, food, and chemical industries. We hereby take HGZP 17D compression tablet machine developed and manufactured by Rich Packing Machinery as an example. This pill press is a smart, Industry 4.0 machine that integrates real-time pressure deviation monitoring, automatic tablet weight adjustment, and auto waste rejection.

●High Capacity: Designed for mass tablet manufacturing, the turret can reach a maximum speed of 110 RPM, yielding an output of up to 75,000 tablets per hour.

●Reliable Materials: Built to last, its turret adopts stainless steel 2Cr13 with high-strength as the construction material. Lower and upper machine structures use tin-mixed QT600, with the surface hardness exceeding HRC 53. This ensures resistance to impact, corrosion, heat, and wear.

●Tablet Weight Control: A servo motor controls the powder filling track, and the system automatically compensates for powder fill volume, resulting in a minimal tablet weight error of ≤±2%. Coupled with a real-time monitoring and rejection system, this tablet presser automatically identifies and rejects any under or overweight tablets.

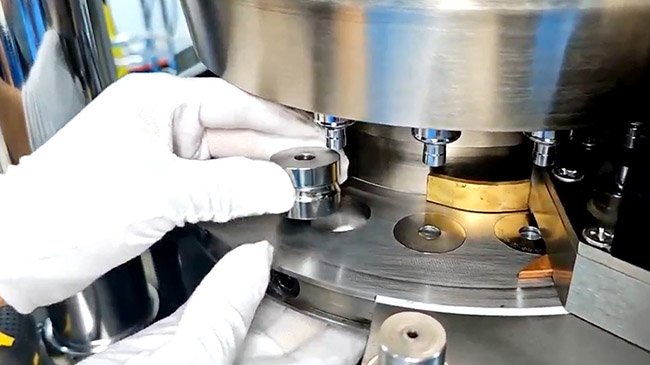

●Quick Tooling Changeover: Thanks to the high precision and perfect fit between the turret and molds, the complete set of tooling can be changed over in a tool-free method within 30 minutes, significantly reducing downtime.

●Operational Safety: This tablet making machine utilizes concave-convex, flat-contact die locking screws instead of conical point-contact screws. This design reduces dies’ risk of being ejected under high pressure, preventing dies from damaging the equipment.

●Pre-Pressing for Tablet Quality: The pre-compression stage eliminates air from both the powder and die cavities. This enhances the plasticity of powder for the main tablet compression, prolongs the contact time of main pressure wheels, and improves finished tablets’ density and structural integrity.

punches, dies, and a turret of an automatic press tablet machine

Selecting your ideal tablet press machine is crucial for efficient tablet production. Before your procurement, you could check with equipment features and capabilities mentioned in this article, and consult industrial professionals for specialized guidance for choosing a pill pressing machine that guarantees safe, high-speed tablet compression operation, and meets global regulatory compliance.