evaluation and hands-on training session for the CGNT-209 semi-automatic capsule filler, reinforcing our global reputation for innovation and customer-centric collaboration.

The client selected Rich Packing’s CGNT-209 semi-automatic capsule filling machine, an upgraded model celebrated for its blend of accuracy, speed, and user-friendly design. Tailored for mid-sized production, the CGNT-209 semi-auto encapsulating machine is a top choice for pharmaceutical and nutraceutical producers worldwide. This encapsulating machine has the following features:

• Dual-Row Capsule Feeding System: Comes with two capsule trays, ensuring high speed and efficiency, with a capacity of 40,000 capsules per hour.

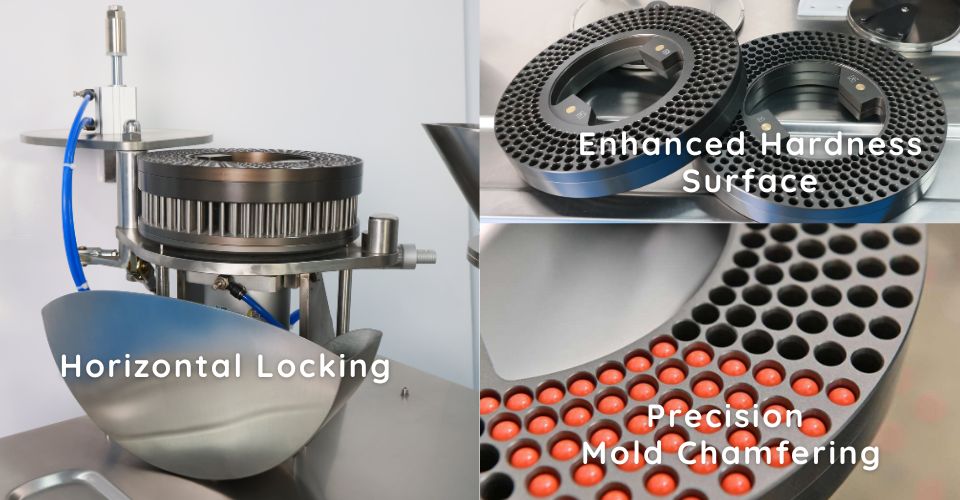

• Specially Treated Capsule Trays: Oxidized for enhanced hardness and a smooth surface, significantly improving capsule feeding success rates.

• Precision-Machined Mold Chamfering: Ensures accurate capsule placement, preventing missing capsules during the process.

• Horizontal Capsule Locking Station: Utilizes a pneumatic activation mechanism for secure locking, reducing labor intensity, minimizing powder leakage, and improving material utilization and product quality.

The client was highly satisfied with its performance, especially the smooth capsule locking and high-speed feeding. They praised the machine’s build quality and user-friendly operation, noting it exceeded their expectations.

Prior to delivery, Rich Packing’s engineers meticulously calibrated the machine to align with the client’s unique requirements, including capsule dimensions (size #0 to #4 compatibility) and powder viscosity. Rigorous in-house trials were conducted to optimize dosing consistency and minimize material waste, ensuring seamless integration into the client’s production line.

During the one-day visit to Rich Packing’s Guangzhou facility, the client engaged in an immersive training program led by Senior Engineer Mr. Yang, a specialist with over a decade of experience in capsule filling technology. Key activities included:

• Live demonstrations: Capsule loading, powder dosing, and ejection processes.

• Skill-building exercises: Adjusting machine settings for diverse formulations and troubleshooting common issues.

• Maintenance deep dive: Best practices for cleaning, lubrication, and component replacement to extend machine lifespan.

The client’s team expressed high confidence in operating the CGNT-209 semi-auto capsule filler independently, praising the clarity of the training and the machine’s intuitive interface.

This collaboration underscores Rich Packing’s dual commitment to cutting-edge technology and unparalleled post-sale support. For the Singaporean client, the visit provided assurance of the CGNT-209’s capabilities and Rich Packing’s dedication to their success. For our team, it reaffirmed our leadership in Southeast Asia’s competitive pharma machinery sector, where demand for agile, high-performance solutions continues to rise.

Rich Packing remains focused on empowering clients worldwide with reliable equipment and expert guidance. We extend our gratitude to the Singaporean team for their trust and look forward to supporting their journey toward production excellence.