A tablet press machine compresses powder or granules into tablets in pharmaceutical nutraceutical and food industries. The right choice should not be determined solely by the highest listed maximum speed. The practical questions are: Can it hold tablet weight and hardness at your target output? Can it avoid common defects at speed? Can your team clean and change tooling fast enough to keep OEE high?

This guide is built for that reality. You’ll first compare the main types (including rotary tablet press models used for continuous production), then learn the working principle so terms like pre-compression, compression force, and dwell time are clear. Finally, you’ll use a short list of 10 critical specs to compare machines and suppliers in a way that matches real production—especially punches and dies (tooling) and changeover time, which often decide the long-term cost and daily performance.

A tablet press machine forms tablets by compressing a measured amount of material inside a die. You may also see “tablet compression machine,” “pill pressing machine,” or “tableting machine.” In most buying contexts, these labels refer to the same core function.

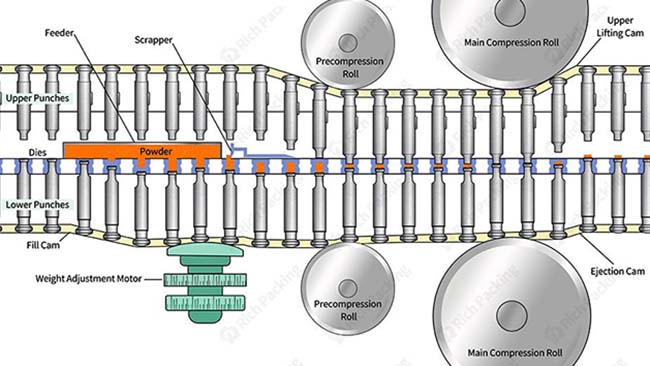

In production, the most common design is a rotary tablet press. A rotating turret holds multiple stations, and each station repeats the same cycle: fill the die, compress the powder, then eject the tablet.

The parts that most affect stability and ease of operation are simple:

● Hopper and feeder: moves powder into the dies and influences how stable filling is at speed.

● Turret and dies: define the die path and tablet size capability.

● Punches and dies: tooling that shapes the tablet and strongly affects defects, wear, and ejection behavior.

● Pre-compression and main compression: staged compression that controls air release and final hardness.

● Ejection and take-off: removes tablets without chipping, sticking, or build-up.

● Dust extraction/containment: keeps the press stable, reduces build-up around tooling, and supports consistent operation.

Keep one principle in mind: you are buying repeatability, not just “ability to press.” Repeatability is what separates a machine that runs smoothly from one that needs constant adjustment.

Rotary tablet presses (multi-station) run continuously and deliver much higher output. More importantly, once tuned, they typically hold weight and hardness more steadily at production speed. For commercial production, a rotary design is the default choice.

Within rotary presses, the “type” you’re really choosing is the configuration. Does the machine have a real pre-compression stage? Does it use gravity feeding or a force feeder? What tablet size and shapes can it support with available punches and dies? These factors often decide whether you can run your product at your target output with acceptable yield and downtime.

A rotary tablet press repeats the same cycle at each station as the turret rotates.

First, powder enters the feed area and fills each die as it passes under the feed frame. Next, the machine meters the fill so a controlled volume remains in the die—this is the basis of tablet weight control.

Many presses then apply pre-compression, a lighter first squeeze. Pre-compression helps remove trapped air and starts consolidation. This stage is especially valuable for blends that trap air, rebound elastically, or show capping/lamination at higher speed.

After that, main compression forms the final tablet. Compression force and the effective time under pressure determine final hardness, thickness, and density. This is where dwell time matters. Dwell time is the effective time the powder experiences compression. As turret speed increases, dwell time usually decreases, which is why some blends look fine at moderate output but lose hardness or develop defects when you push the machine faster.

Finally, to discharge the finished tablet, the lower punch moves upward. Take-off transfers it out of the press, and dust control helps prevent build-up around tooling that can trigger sticking, picking, or weight drift.

rotary tablet press working principle

Once you see the cycle clearly, the buying logic becomes clear too: stable filling, a workable compression window (often with pre-compression), sufficient dwell time at your target output, and clean ejection—plus changeover that fits your schedule.

Use these ten items to compare models and suppliers in a way that matches real production. They focus on sustained output, defect risk, tooling economics, and changeover performance.

|

# |

Critical spec |

Why it matters |

What to confirm (ask + verify) |

|

1 |

Real output at your target tablet (tablets/hour under your weight + hardness) |

Brochure speed is not sustained output |

Run a 1–2 hour trial with your formula (or a close match): record output, weight variation, hardness/thickness stability, scrap rate |

|

2 |

Type & configuration |

Determines stability and ceiling for commercial runs |

Confirm station count and whether pre-compression is a true independent stage you can tune and repeat |

|

3 |

Turret speed & dwell time |

Quality often drops at high speed because dwell time shrinks |

Compare results at different speeds: watch hardness, capping/lamination, and whether force must climb too high to hold quality |

|

4 |

Main compression force (kN) (compression force) |

Defines the workable compression window, not just “max power” |

Ask for the recommended working range for your tablet size and targets; verify force curves and hardness stability in a trial |

|

5 |

Pre-compression force (kN) (pre-compression) |

Removes air and reduces capping/lamination risk |

Adjust pre-compression during trial runs and confirm defect rate drops without creating new issues |

|

6 |

Max tablet size & shape capability |

Large diameter, deep score, and odd shapes amplify stress problems |

Test your target shape: check cracks/chips/score quality and whether speed must be reduced to keep yield |

|

7 |

Weight control & dosing range (fill depth / feedback control) |

Weight consistency drives compliance and scrap rate |

Verify weight variation and how quickly the press returns to stable control after changes |

|

8 |

Tooling system (punches and dies) (standard, availability) |

Tooling drives long-term cost, lead time, and defect control |

Confirm tooling standard (e.g., B/D), lead time, fit repeatability, and surface options for sticky blends |

|

9 |

Feeding system (gravity vs force feeder) |

Poor flow quickly becomes weight variation and lost output |

If the blend doesn’t flow well, confirm force feeder options and verify uniform fill at your target speed |

|

10 |

Changeover & cleaning design (changeover) |

Changeover often decides real OEE and delivery performance |

Time a full swap to first-good-tablet; check access, quick-release features, and cleaning “dead zones” |

A key point: impressive “max force” and “max speed” numbers do not guarantee stable tablets. Many real problems come from the interaction of feeding, pre-compression, dwell time, and tooling—plus how frequently you change over between SKUs.

Start with how your material behaves. If the powder is free-flowing, many machines can look good in a short demo. The difference shows up when the blend is less cooperative: low bulk density, electrostatic behavior, wide particle size distribution, hygroscopic ingredients, high-fat blends, or simply batch-to-batch variability. In those cases, the feeding system and weight control method become the first “make or break” decision. A force feeder often turns unstable fill into consistent fill, especially as output rises.

Next, evaluate air release and rebound. Capping and lamination are common when air can’t escape fast enough or the compact rebounds after compression. That is exactly what pre-compression and dwell time address.

Pre-compression provides an early consolidation step that helps air move out; dwell time provides bonding time under pressure. If you only increase main compression force to fight these defects, you may raise hardness but also increase heat, sticking, and tooling wear—making the press harder to run over time.

Tablet geometry matters too. Large diameter tablets, deep score lines, embossing, and irregular shapes concentrate stress and can increase edge cracking, chipping, and appearance defects during ejection. This is where punches and dies selection and finish directly affect yield. If your product mix includes multiple shapes, then changeover is not a “maintenance detail.” It’s part of the production strategy, because tooling swaps and cleaning determine your real weekly output.

Finally, match the press to your operating rhythm. If you run long campaigns, changeover time is less critical. If you run many SKUs, a slightly slower press with a better changeover design can produce more saleable tablets per week than a higher-speed machine that takes hours to switch and stabilize.

Tablet press tooling affects more than tablet appearance. Punches and dies influence friction, heat, air release behavior, ejection smoothness, and how sensitive the process is to minor variation. If a press runs well initially and then gradually shows sticking, rough surfaces, chipping, or increasing scrap, tooling wear or build-up is often involved.

Treat tooling standardization as a procurement decision. Widely used standards typically improve availability, shorten lead times, and reduce long-term cost. They also make troubleshooting easier because you can compare performance between tooling sets without changing multiple variables at once.

In day-to-day operation, watch simple signs early: dull embossing edges, micro-chipping, rising ejection resistance, or a slow increase in sticking/picking. These trends don’t just affect quality; they usually slow cleaning and changeover as well. A stable process depends on consistent tooling quality, suitable surface options for your blend, and a basic inspection/rotation plan rather than “run until it fails.”

Changeover is where efficiency becomes real. A high-speed press can still underperform if it takes too long to remove tooling, clean, reassemble, align, and stabilize. For multi-SKU production, changeover often dominates weekly output.

Measure changeover properly: from the last good tablet of Product A to the first good tablet of Product B, including cleaning and stabilization. That number is more useful than any generic “fast changeover” claim. In comparison demos, watch how many tools are required, whether parts return to position repeatably, and whether cleaning access is straightforward or full of powder traps.

A well-designed press makes changeover repeatable and low-risk. That matters for throughput, but also for cleanliness and cross-contamination control—especially if you operate under GMP or any strict internal quality system.

Documentation is not just for regulated pharma. It determines how quickly you can install, qualify, and maintain the press without constant disputes. At minimum, confirm clear equipment identification, material and surface details for product-contact parts, a practical approach to calibration (especially for compression force measurement), and a maintenance plan that protects repeatability.

If you operate under GMP, look for structured support: clear acceptance tests, consistent technical answers, and documentation that makes qualification work manageable. The goal is simple: after maintenance or part replacement, you should be able to return the tablet making machine to controlled, repeatable settings—not “tune it from scratch.”

Most issues trace back to a few levers.

Capping and lamination often worsen at higher speed. In those cases, pre-compression and dwell time are usually the first levers to evaluate, not just higher main compression force. A stronger, well-controlled pre-compression stage often reduces defects while keeping main force in a safer range.Sticking and picking often involve friction, heat, and surface interactions. Tooling finish, temperature at the punch tip, dust control, and the force/speed window all matter. If operators continuously increase compression force to maintain hardness, they can unintentionally increase heat and adhesion. Better punches and dies choices and a balanced compression window often solve more than brute force.

Weight variation is commonly a feeding and metering problem. If weight drift increases with speed, look at the feeding system (often a force feeder requirement), fill stability, and how weight control responds to changes. Many “accuracy complaints” are actually “fill consistency complaints.”

Chipping and edge cracks often relate to tablet geometry, ejection conditions, and tooling wear. If defects appear right after a changeover, check tooling fit repeatability and setup discipline before blaming the blend.

The initial purchase price is just one factor in the total cost. Over time, total cost is dominated by uptime, scrap, tooling life, changeover time, and how quickly you can recover from problems. A good supplier supports realistic trials, stable spare parts supply, and preventive maintenance guidance so the machine does not drift out of control after a few months.

When you compare suppliers, ask about parts lead time, training quality, service response, and whether they can help tune the compression window for your blend rather than only delivering equipment. For example, manufacturers such as Rich Packing often position rotary press projects around commissioning support and practical production guidance because stable output and changeover performance usually matter more than peak-speed claims.

If two presses look similar on paper, the better choice is usually the one that makes the process easier to control week after week: stable feeding, controllable pre-compression and main compression, adequate dwell time at target output, reliable tooling support, and faster, cleaner changeover.

In most purchasing contexts, yes. Both refer to equipment that compresses material into tablets.

Force depends on tablet size, target hardness, and formulation behavior. Confirm the workable range through a trial run, not just the maximum rating.

It helps remove trapped air and starts consolidation before main compression, reducing rebound-related defects at speed.

Dwell time refers to the duration that the material is under full compression. Higher speed typically reduces it, which can reduce bonding and increase defects if the process window is tight.

Confirm the tooling standard and availability, then watch wear signals such as rising sticking, rough surfaces, chipping, and inconsistent appearance.

Time a full changeover from last good tablet to first good tablet, including cleaning, reassembly, alignment checks, and stabilization.

ISPE – C&Q topic page:

https://ispe.org/topics/commissioning-qualification

USP <701> Disintegration (PDF):

https://www.uspnf.com/sites/default/files/usp_pdf/EN/USPNF/generalChapter701.pdf

USP <1216> Tablet Friability (PDF archive):

Pharmaceutical Technology – tooling standards discussion: