Stick Packing Machine

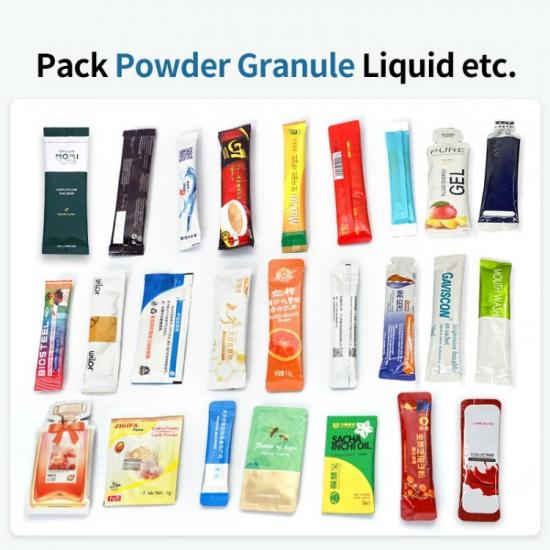

In the pharmaceutical industry, a stick packing machine is a specialized packaging equipment designed to efficiently encase products in stick-shaped pouches or sachets. The machine is commonly used for unit-dose packaging of powders, granules, or small solid medications (e.g., oral rehydration salts, instant drink mixes, or single-dose supplements) into elongated, sealed strips. They ensure precise dosing, hygiene, and portability, which are critical for pharmaceutical applications.

This automatic pouch packing machine has widely applications, easily handle kinds of stick types, as three side sealed, four side sealed, back side sealed and more.

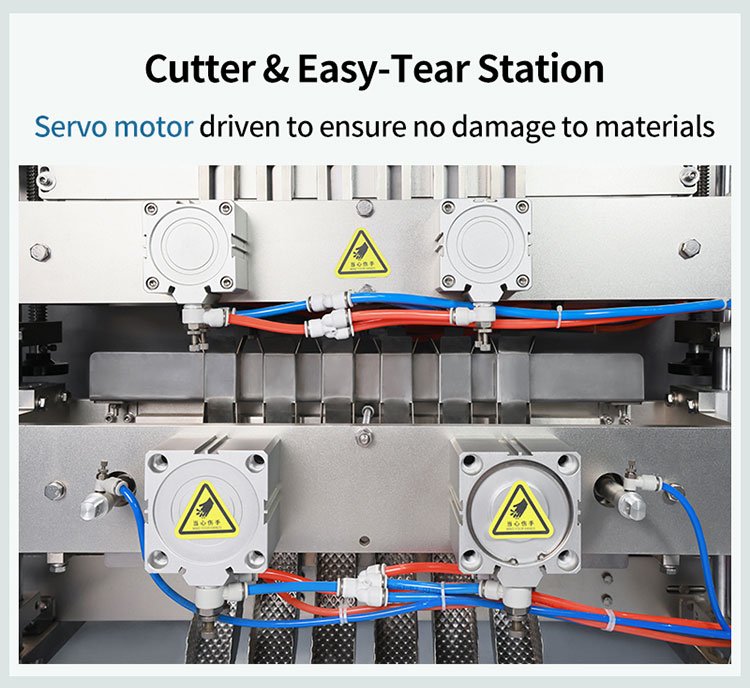

This stick packing machine has core technology advantages, as fully automatic integrates servo motor control and PLC touchscreen operation, achieving output speeds up to 245 sticks/m with ±0.5g precision. The multi lane heat sealing device ensures complete air isolation, extending shelf life of sensitive pharmaceutical ingredients by 30% compared to conventional packaging.

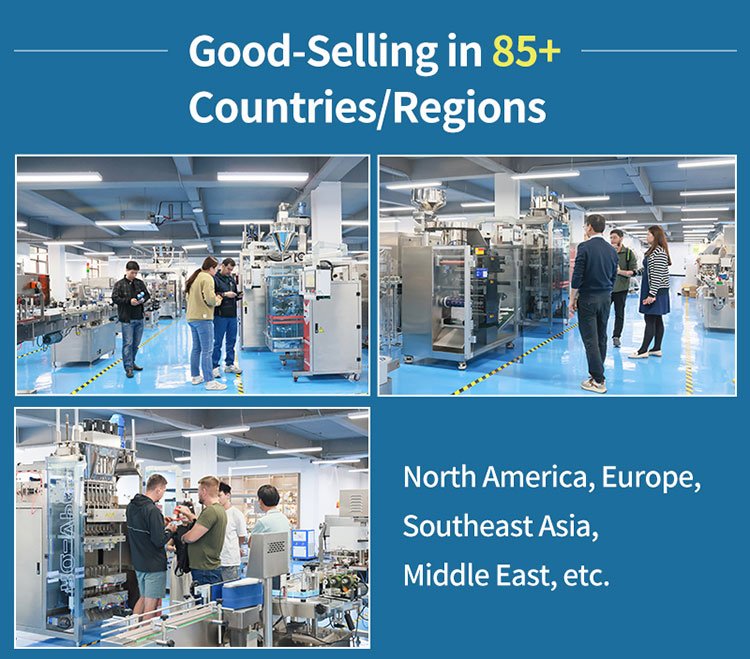

Our powder stick packaging machines have high Precision and Hygiene, adhere to strict pharmaceutical standards (e.g., GMP and ISO 9001 certifications), ensuring contamination-free packaging.

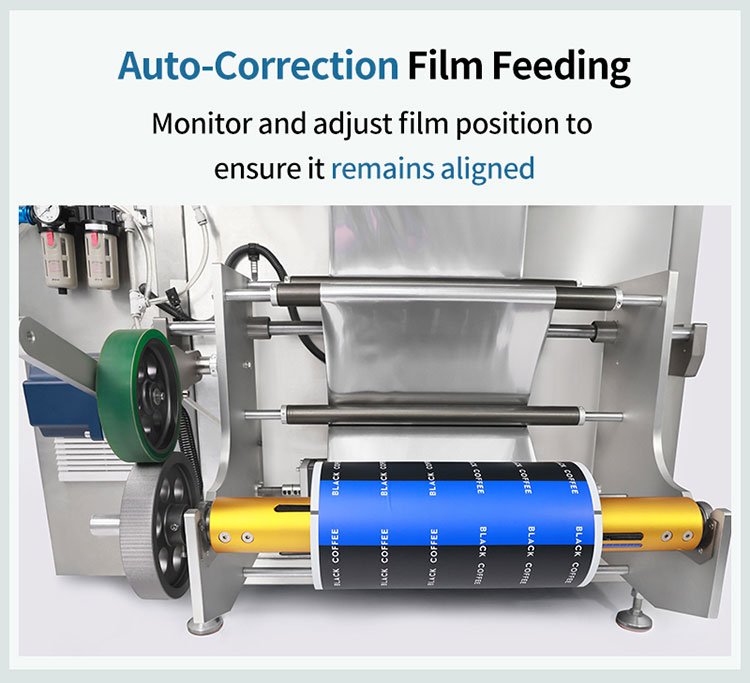

It can handle materials like composite film, aluminum foil composite material, aluminized film, shrink film (PE/PVC/POF), etc.,.

Our company's RP-SPM sachet stick packaging machine adopts a full servo motor feeding system to provide customers with high-precision quantitative material filling, which is different from the models of peers, especially in the pharmaceutical industry and nutritional products industry to ensure higher packaging accuracy.

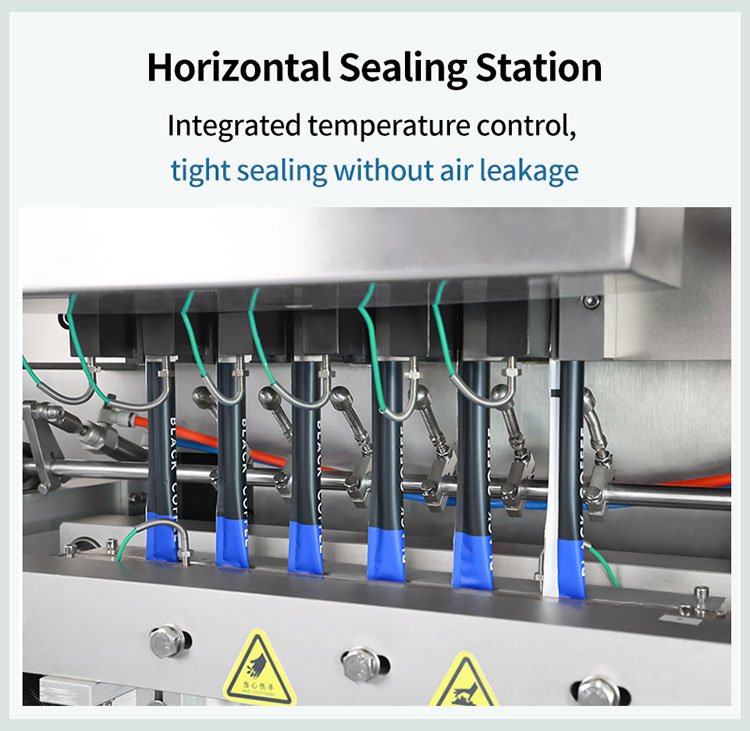

In addition to being compatible with various sealing styles, the heat sealing mold of RP-SPM vertical form fill seal machine is also made of CNC one-time processing, and the high-strength aluminum alloy material makes it have higher molding stability during heat sealing. Both the end seal and the horizontal seal use integrated temperature control, and the sealing effect is very tight and does not leak materials or air.

| Name | Multi-lanes Stick Packing Machine |

| Max. film width | 480mm |

| Bag style | 3/4 side, Back, Rear-center sealed, stick sachets |

| Available lane | 6 lanes |

| Capacity | 30-40 cycles/min/lane |

| Control style | PLC controlling system and touch screen |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

IPv6 network supported

IPv6 network supported