High-Efficiency Tablet Coating Machine

| Product Name | High Speed Tablet Coating Machine |

| Capacity | 10-65 kg/batch |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

High-Efficiency Tablet Coating Machines - Precision, Reliability, and Compliance for the Pharmaceutical Industry

In today's rapidly evolving pharmaceutical industry, global pharmaceutical companies are striving to meet stringent regulatory standards while optimizing production efficiency, leading to an increasing demand for high-efficiency tablet coating machines. Rich Packing, a trusted manufacturer with over 32 years of experience in pharmaceutical and packaging machinery, has developed a new generation of automatic tablet coating machines that better enhance performance, consistency, and compliance.

This comprehensive guide will explore the definition of tablet coating machines, why modern pharmaceutical companies need high-efficiency models, and Rich Packing's innovative coating solutions. Whether you are sourcing a tablet coating machine for a new facility or upgrading existing equipment, this article will provide valuable information for various practical needs.

What is a Tablet Coating Machine?

A tablet coating machine (also known as a tablet coater or pill coating machine) is a specialized piece of equipment used in the pharmaceutical industry to apply a thin, functional, or aesthetic coating to solid dosage forms such as tablets or pills made by tablet press machine. This coating serves several key purposes:

Masking unpleasant tastes or odors

Protecting active ingredients from moisture, light, or gastric acid

Enabling controlled or sustained release of the drug (enteric coating)

Improving ease of swallowing and patient compliance

Allowing for the addition of branding elements (e.g., logos, colors, etc.)

The process typically involves placing uncoated tablets into a rotating drum (coating pan) while simultaneously spraying a precisely atomized coating solution and blowing hot air onto the tablet bed for rapid drying.

While coating machines have existed for decades, with small-scale producers or startups often using tablet coating pans, the need for increased production capacity and stricter regulations has driven pharmaceutical equipment manufacturers to continuously develop new, high speed tablet coater machines. These now integrate intelligent automation, precision engineering, and hygienic design to meet cGMP, FDA, and EU GMP requirements while maximizing yield and minimizing waste.

Why Choose Rich Packing's High-Efficiency Tablet Coating Machines?

At Rich Packing, we don't just manufacture machines; we are committed to providing tailored solutions to the real-world challenges faced by pharmaceutical companies worldwide. Our automatic tablet coater combines high-end electrical components and parts from world-renowned brands, an intelligent control system, and a user-centric design to deliver superior reliability and efficiency. Here are six key advantages that make our system stand out in the pharmaceutical coating machine industry:

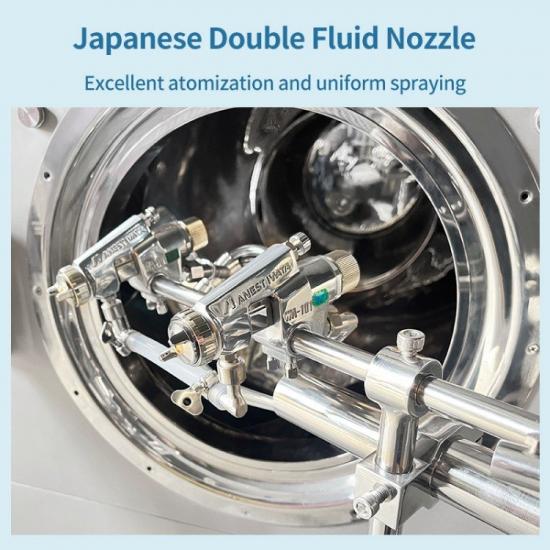

1. Japanese Dual-Fluid Nozzles: Superior Atomization for Perfect Coating

Achieving uniform coating requires better and more even spraying. Our machine is equipped with high-quality dual-fluid nozzles from Japan, renowned for their exceptional atomization performance. These nozzles combine compressed air and liquid flow to produce a fine, uniform mist with the following characteristics:

High atomization rate (smaller droplet size for even distribution)

Minimized overspray (reducing raw material waste by up to 15%)

Stable spray pattern across varying viscosities

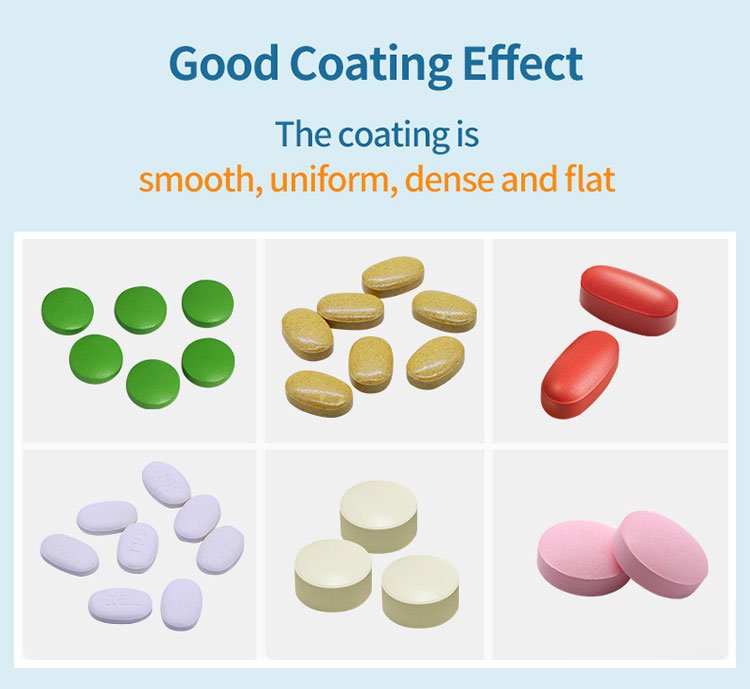

This ensures that each tablet receives the same coating layer, eliminating common defects such as uneven thickness, "orange peel" texture, spotting, multiple tablets sticking together, or uneven color. This not only saves significant production materials but is also crucial for producing high-value, high-precision pharmaceuticals.

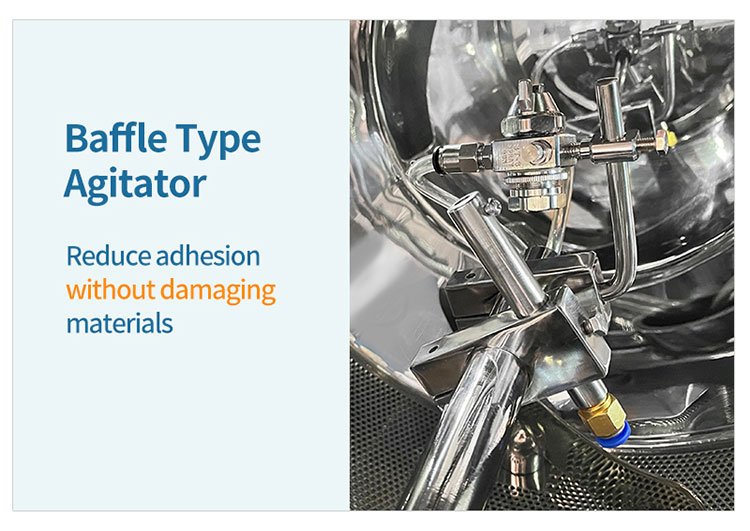

2. Flow-Guiding Agitator Design: Gentle and Thorough Mixing and Coating

One of the biggest challenges in tablet coating is achieving complete tumbling motion without damaging fragile tablet cores or causing excessive abrasion. Traditional paddle or blade agitators often lead to:

Material sticking to the pan walls

Edge chipping or surface abrasion

Dead zones resulting in uneven coating coverage

Rich Packing's proprietary flow-guiding agitator structure addresses these issues. By cleverly designing internal baffles and optimizing rotational dynamics, our system ensures:

360° tumbling of every tablet without dead zones

Reduced adhesion of coating solution to the surface

Gentle handling, maintaining the integrity of even soft or scored tablets

This design not only improves coating uniformity but also extends batch life and reduces reject rates.

3. Siemens PLC + HMI: Intelligent Control, 20 Recipe Memory Functions

In the modern pharmaceutical industry, automation is crucial. Our high-efficiency tablet coating machine is equipped with a German Siemens PLC and full-color HMI human-machine interface, offering the following features:

Comprehensive parameter control: All parameters, including spray rate, drum speed, inlet and outlet air temperature, and airflow, can be digitally monitored and adjusted in real time.

20 preset coating recipes: Allows for product changeovers in minutes, not hours. Ideal for multi-product manufacturing facilities requiring frequent batch changes.

Audit trail and data logging: Compliant with 21 CFR Part 11 electronic record regulations.

Durable and long-lasting: Utilizing German Siemens electrical components, the high-efficiency coating machine can operate continuously for over 10 years with minimal maintenance costs.

4. Precise Temperature Management: Preventing Tablet Coating Defects

Coating defects such as "sticking," "bridging," or "orange peel" are often caused by poor temperature control. Our machine integrates a dual-zone temperature monitoring system that simultaneously monitors:

Inlet air temperature (for solvent evaporation control)

Tablet bed temperature (real-time monitoring of core temperature via non-contact sensor)

Advanced PID algorithms dynamically adjust heating and airflow to maintain optimal drying conditions. This prevents:

Overheating (which can lead to melting of binders or APIs)

Insufficient drying (leading to stickiness and clumping)

Intra-batch temperature gradients

This ensures flawless coating results, even for heat-sensitive formulations or complex multi-layer coating applications.

5. Fully Sealed and cGMP Compliant Construction

In the pharmaceutical industry, stringent manufacturing standards are required worldwide, and these requirements must be met during the coating process. Rich Packing's tablet coating machines are designed to exceed global standards:

The fully sealed enclosure features a negative pressure design to prevent leakage of coating liquid or dust, protecting operators and the cleanroom environment.

All product-contact parts are made of SUS-316L stainless steel and electropolished to a surface roughness of Ra ≤ 0.4 µm for optimal cleanability and corrosion resistance.

There are no dead corners or crevices in the piping and drum design.

Compliant with cGMP, FDA, and EU requirements for sterile and non-sterile manufacturing. Our commitment to quality ensures your factory can confidently pass audits and maintain product integrity from the first batch to the ten-thousandth.

6. One-Touch CIP Cleaning System: Reduce Downtime, Increase Tablet Production Efficiency

Production shift changeover time directly impacts overall equipment efficiency. Our automatic coating tablet machine features an integrated self-cleaning system that:

Starts with the push of a button

Uses programmable cleaning cycles with water or cleaning agents

Cleans nozzles, the inside of the coating pan, filters, and exhaust channels

Records cleaning parameters to ensure compliance

Practical Applications in the Pharmaceutical Field

Rich Packing's tablet coating equipment serves numerous clients, including:

Generic or branded drug manufacturers requiring cost-effective, high-volume coating

Biotechnology companies requiring precise enteric or sustained-release coatings

Contract development and manufacturing organizations (CDMOs) managing multiple client projects

Nutraceutical manufacturers adding functional or aesthetic films to vitamins and dietary supplements

Whether you are handling 5 kg or 500 kg tablet coating batches, we have low, medium, and high-volume models to meet your needs through modular design.

We believe a truly efficient tablet coating machine should possess the following characteristics:

Saves materials through precise spraying and minimized waste

Optimizes energy consumption through intelligent airflow and heating control

Reduces labor costs through automation and quick changeovers

Ensures quality through repeatable and verifiable processes

Ensures regulatory compliance through comprehensive traceability and compliant materials

Rich Packing's solutions meet all these requirements – without compromising the robustness and maintainability of the equipment.

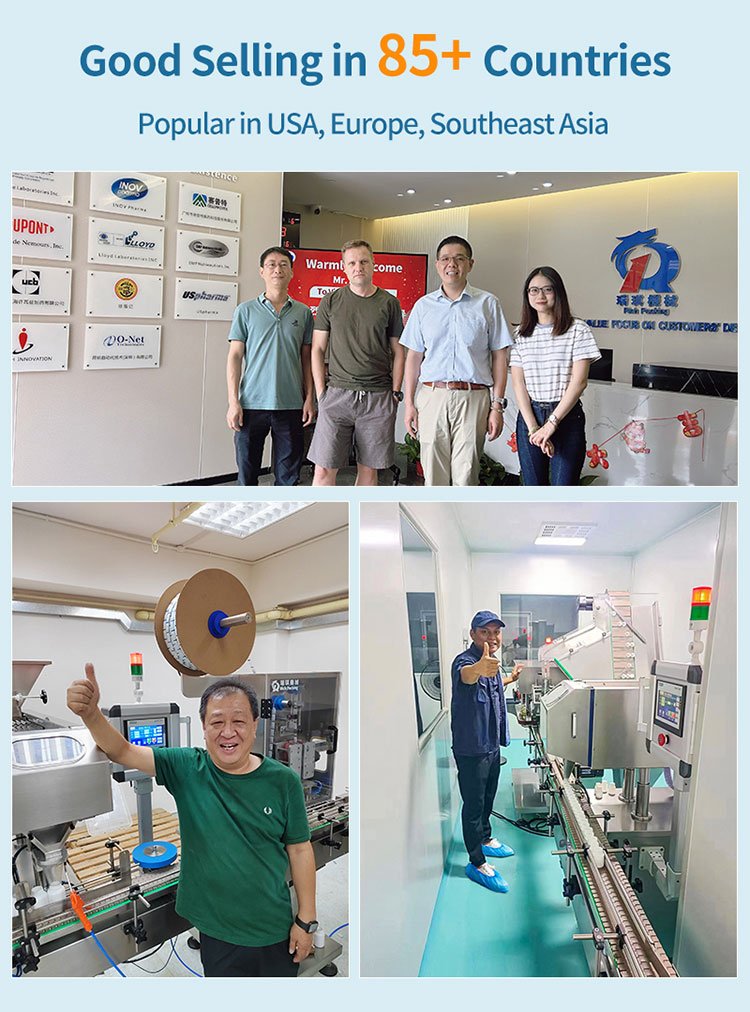

Our high-efficiency tablet coating machines perfectly balance advanced technology, reliability, and global compliance – all thanks to our decades of engineering excellence and customer support in over 80 countries.

Visit our website or contact our international sales team today. Let's work together to create a coating solution that grows with your business.

IPv6 network supported

IPv6 network supported