NJP 1200C Automatic Capsule Filler Capsule Filling Machine of Rich Packing

*** Technical parameter

|

Production capacity |

72000 pcs/h |

|

Net weight of machine |

1100Kg |

|

Overall size of machine |

1100×910×2100MM |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

000,00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

The Ultimate Guide to Choosing an NJP Capsule Filling Machine: Solutions for Nutraceutical Manufacturers

Introduction: Why Speed, Flexibility, and Precision Define the Nutraceutical Game

The global nutraceutical and dietary supplement market is characterized by rapid product cycles, diverse formulations (from complex herbal extracts to sensitive probiotics), and intense pressure for cost-effective, high-volume production. For manufacturers in this sector, the equipment used is not just a cost center—it is a critical determinant of market agility and profitability.

While many generic encapsulation machines exist, specialized equipment, particularly high-performance automatic models like the capsule filling machine automatic series, offers the precision and reliability required to handle the industry's unique challenges.

This comprehensive guide, tailored specifically for procurement managers and production engineers in the supplement industry, explores the features, benefits, and crucial buying considerations for choosing a best-in-class automatic capsule encapsulation machine, focusing on the advanced capabilities of the RICH PACKING NJP 1200 capsule filling machine.

Section 1: Analyze the Core Pain Points of Nutraceutical Producers

To maintain a competitive edge, supplement manufacturers must overcome four primary hurdles. Your automatic capsule making filling machine must be the solution, not the source, of these problems.

1. The Challenge of Formula Diversity and Changeover Time

Unlike pharmaceutical giants that might run blockbuster drugs for years, supplement companies constantly launch new blends (e.g., adaptogens, mushroom complexes, specialized vitamins) and capsule sizes.

Pain Point: Long changeover times (the time spent switching from one product to another) result in costly production downtime, reducing annual capacity and delaying time-to-market for new products.

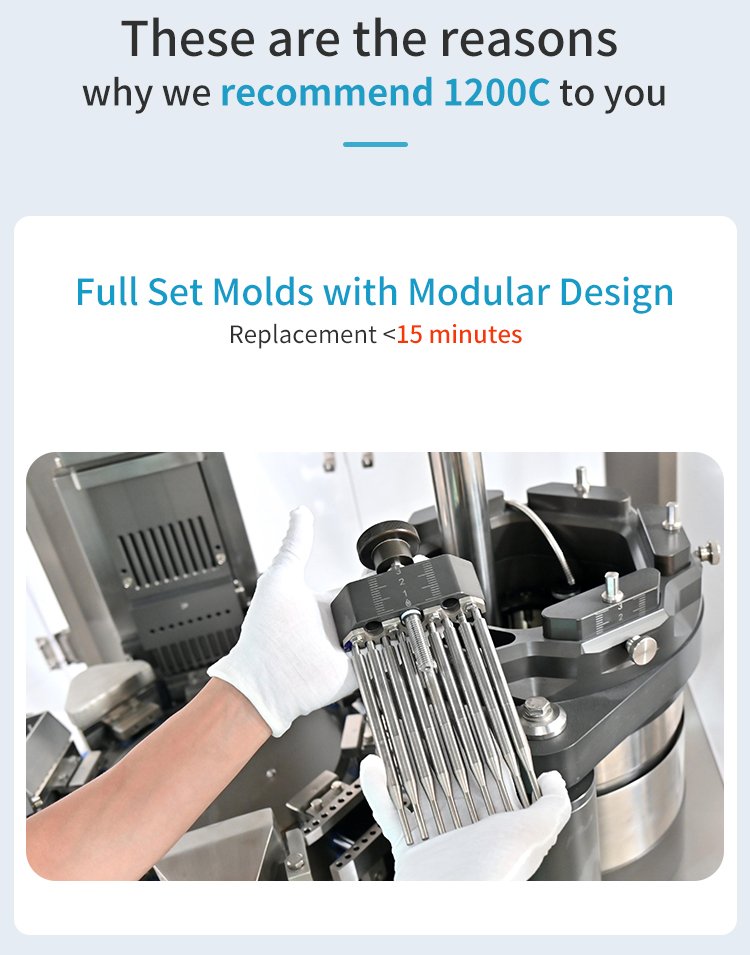

The Solution: The ideal NJP capsule filling machine must offer quick, tool-free or minimal-tool changeover systems. This feature is non-negotiable for flexible manufacturing.

2. Handling Complex and Sensitive Raw Materials

Nutraceutical powders—such as sticky plant extracts, abrasive minerals, or moisture / heat-sensitive probiotics—present unique filling challenges.

Pain Point: Standard volumetric dosing systems often fail to accurately fill low-density, highly cohesive, or sticky powders, leading to significant weight variations and material waste.

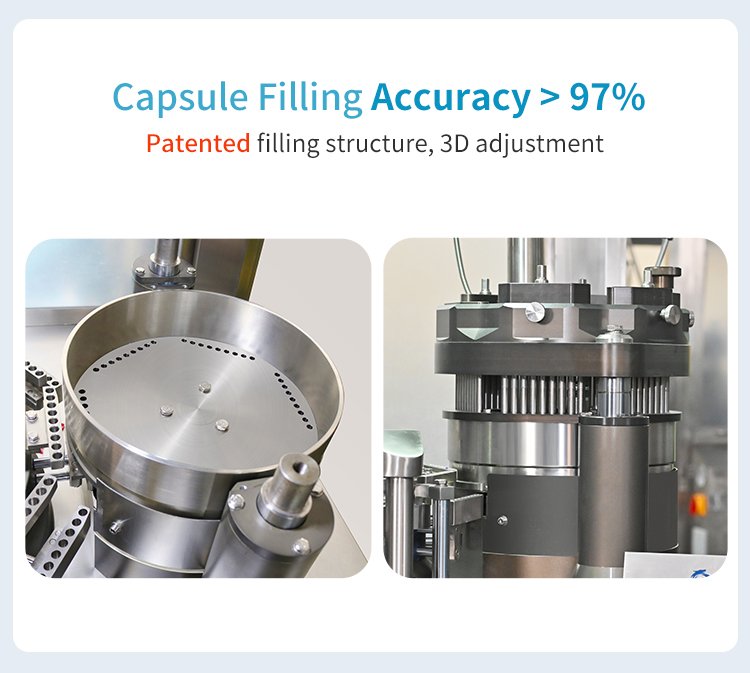

The Solution: Look for a robust NJP capsule filler machine with specialized feeding and dosing technologies, micro-dosing modules) that maintain high accuracy (3%-5%) even with challenging materials. The material contact parts must be highly durable and chemically inert.

3. The Demand for High Output and Accuracy

Profitability is directly linked to output and yield. Maximizing the amount of usable product per batch is paramount.

Pain Point: Inefficient feeding, capsule separation failures, or excessive powder spillage lower the overall equipment effectiveness (OEE) and inflate raw material costs.

The Solution: A high-speed capsule filling machine automatic model, such as one capable of 72,000 to 150,000 capsules per hour, is essential. Crucially, this speed must be paired with precision to minimize the reject rate.

Section 2: Technical Deep Dive into the NJP Series: Why the NJP-1200C Excels

The NJP series represents the current standard in intermittent motion, high-speed capsule fillers. The RICH PACKING NJP-1200C model, specifically, is engineered to address the nutraceutical sector's needs head-on.

Feature 1: The Principle of Segmented Dosing Precision

The core of any automatic encapsulator is its dosing method. The NJP series utilizes a precise rotating tamping pin system.

Function: Powder is gently filled into the dosing disc and then compressed by multiple sets of tamping pins before being ejected into the empty capsule body.

Benefit for Supplements: This method is highly effective for consolidating low-bulk-density powders and ensures a consistent powder plug, leading to industry-leading filling accuracy and low standard deviation. This is crucial when dealing with expensive, high-potency ingredients.

Feature 2: High-Speed Throughput for Peak Demand

The NJP 1200 capsule filling machine designation often refers to its high output capacity.

Capacity: With an output capability generally exceeding 72,000 capsules per hour, this machine allows manufacturers to scale up rapidly during peak selling seasons.

Mechanism: The intermittent indexing turret design minimizes vibration and maximizes running time, directly translating to higher OEE.

Feature 3: Gelatin and HPMC Versatility

The supplement market increasingly utilizes vegetarian capsules (HPMC) alongside traditional animal-based gelatin capsule filling machine applications.

Versatility: Advanced NJP models are designed with specialized vacuum separation and alignment mechanisms that reliably handle both gelatin capsule filling machine materials and the slightly softer HPMC shells without crushing or denting them. This flexibility is vital for catering to diverse consumer preferences.

Section 3: Strategic Considerations for Procurement Managers (E-E-A-T Focus)

Selecting a reliable supplier is as crucial as selecting the right NJP capsule filling machine. This is where the Experience and Trustworthiness of the manufacturer, such as RICH PACKING, become paramount.

A. The Importance of Comprehensive After-Sales Support

Equipment downtime can cost tens of thousands of dollars per day. A manufacturer's service commitment mitigates this risk.

Global On-Site Service: RICH PACKING offers global on-site service, covering installation, commissioning, and specialized operator training. This ensures the machine is validated and production-ready quickly, fulfilling the "Experience" aspect of E-E-A-T.

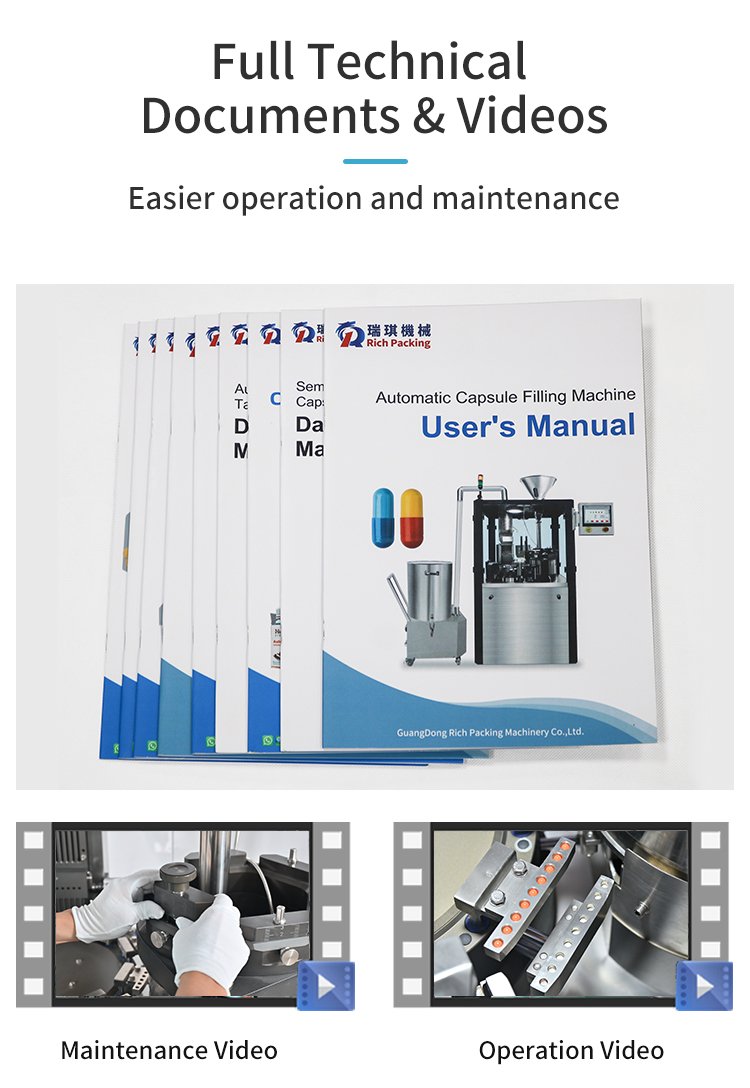

Technical Documentation: Complete technical support, including user manuals, daily operation guides, and video instructions, empowers in-house teams for self-sufficiency.

Warranty and Parts: A 3-year warranty on components and free 1-year wearing parts significantly lowers the total cost of ownership (TCO) in the initial years, demonstrating "Trustworthiness."

B. Integration Capabilities and Future-Proofing

Your automatic capsule encapsulation machine should integrate seamlessly into a complete packaging line.

Modularity: The NJP-1200C capsule machine's design allows for easy integration with upstream equipment (like powder mixers) and downstream machines (e.g., Capsule Polishing Machines, Automatic Counting Machine, Blister Packing Machine, and Cartoning Machine). This modularity prevents bottlenecks and maximizes throughput across the entire workflow.

Compliance for Export: The availability of services like DDP (Delivered Duty Paid) and DDU (Delivered Duty Unpaid) shipping simplifies international logistics, which is vital for supplement companies selling globally.

Section 4: Maintenance and Longevity: Sustaining Peak Performance

To ensure the NJP capsule filling machine maintains its 99% efficiency over years of high-speed use, adherence to strict maintenance protocols is essential.

1. Cleaning and Dust Management

Nutraceutical powders often contain abrasive ingredients.

Protocol: Daily cleaning protocols must emphasize the sealed, enclosed dosing area. The machine should feature effective dust extraction ports and a robust vacuum system to prevent cross-contamination between different vitamin or herbal blends.

2. Lubrication and Component Inspection

The intermittent turret and tamping pin station are the machine's heart.

Checklist: Regular inspection of the indexing gearbox, lubrication levels, and the condition of the cam and followers is critical to prevent wear and tear. Use only manufacturer-approved lubricants to maintain component integrity.

3. Wearing Parts Management

Despite a long warranty on main components, wearing parts need constant management.

Free Spares: Leveraging the free 1-year wearing parts provided by RICH PACKING allows manufacturers to plan maintenance proactively rather than reactively, minimizing unexpected breakdowns. These parts typically include seals, springs, and certain alignment pins.

Conclusion: Securing Your Future with the Right Encapsulation Partner

For nutraceutical and dietary supplement manufacturers, the choice of an automatic capsule filling machine is a strategic decision that directly impacts profitability, compliance, and market responsiveness.

The high-precision, high-speed capabilities of the NJP 1200 capsule filling machine, combined with its quick changeover design, directly address the industry's critical need for flexibility and efficiency. When partnered with a reliable manufacturer like RICH PACKING, offering crucial global support, comprehensive warranties, and complete validation documents, you secure a powerful competitive advantage.

Invest in a machine that is built for today's diverse formulations and tomorrow's scaling demands. The NJP capsule filling machine is more than equipment; it is the engine of your supplement business growth.

This is not just an equipment but also as a good assistant and good experts, and this automatic capsule filler machine even can be good in dealing with the poor flow ability things. This 1200C equipment is sure to be a surprising equipment to make anyone, who meets it just see its error rate is extremely low almost fully no mistake at all. Don’t be afraid of using 1200C with difficulty, because its usage is far too easy to be unbelievable and of course the design of the capsule machine in everything is logical. *** Applications

*** Gelatin hard capsule filling machine can be added once to keep smooth of drive mechanism, so it has no maintenance sophistication when the maintenance of its is needed and it meets GMP standard laws.

*** No lubricant oil will be leaked from this machine and this machine is not noisy but it is very very quiet during the whole running of capsule filling.

*** No powder will be allowed to fall into the inside environment body of turntable, and people can see these sealing performance is very good.

*** Why choose ours NJP-1200C model? No dust performance of this fully automatic capsule filling machine doesn’t have any dust flow, and the turntable doesn’t need any lubricant oil so 1200C doesn’t need to be maintained.

Molds of this capsule filling machine automatic big scale can be replaced within a very very short time of 15 min, and it has nothing pollution but very clean on the upper and the lower dies.

The whole cleaning system is good to make this equipment clean nothing dirty, but very clean and this machine will not hurt any capsule but to show all people good quality of capsules.

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

ATV320U07N4C |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

MTD-37-Y0.75 |

1 |

Omate |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwan daojin |

|

Vacuum pump(wet) |

RX25-V-0.3 |

1 |

Taiwan Ruixu |

|

Dust collector |

RQJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

IPv6 network supported

IPv6 network supported