ZH-320W High Speed Cartoning Machine

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

*** Technical parameter

|

Model |

RQ-ZH-320W Cartoner Machine |

|

Speed |

150-320 cartonS/min |

|

Powersupply |

220/380V 50/60Hz |

|

Requirements of instructions |

range of folding times of instructions:1-4 fold |

|

instructions weight: 60-70g/㎡ |

Guangdong Rich Packing has successfully developed the RQ-ZH-320W horizontal cartoning machine by deeply integrating foreign cutting-edge technologies and accumulating its own scientific research results. This model is a model of the new generation of fast cartoning machines, and its various performance indicators meet the cGMP production standards. In terms of key technologies such as pushing materials and carton forming, the 320W automatic cartoning machine has reached the international advanced level of Europe and the United States, and is comparable to it. This series of cartoner machines is mainly aimed at companies in the pharmaceutical, chemical, food, health care products, medical equipment and other industries that have high requirements for high-speed cartoning.

The 320 series cartoning machine launched by Rich Packing has a wide range of applicable packaging materials. The packaging specifications can be easily changed by fine-tuning a few parts, which greatly improves the flexibility of production. The machine is highly intelligent, and can achieve fully automated operation from material unloading, carton adsorption and forming, track transmission, to manual and material detection, tongue insertion, box sealing, and waste removal.

1. The ZH-320W cartoner machine automatic’s body is made of high-quality stainless steel or carbon steel to create industrial-grade durability

As the core structure of the high-speed cartoning machine, the body of the RQ-ZH-320W is made of medical-grade stainless steel (SUS 304) and industrial carbon steel (Q235B). Compared with other models of the same industry, our company's machine service life is increased by 3 times, and the maintenance cost is reduced by 40%, ensuring the long-term stability of the equipment in harsh environments. The body has high-strength corrosion resistance. The machine will undergo a strict 72-hour salt spray test before leaving the factory, and it can withstand detergents with a pH of 2-12, perfectly matching the high-frequency disinfection needs of the pharmaceutical industry. The integrated cartoning machine body structure, the carbon steel frame is strengthened by heat treatment, the static load capacity is 5000kg, and the vibration amplitude is controlled within ±0.05mm. All contact surfaces are mirror polished (Ra≤0.8μm), there is no sanitary dead corner, and it meets the FDA 21 CFR Part 177.2600 material standard.

2. Intelligent filling quantity monitoring system, redefining packaging accuracy

By integrating the dual technologies of quantity detection sensor + AI algorithm, millimeter-level control of the cartoning process is achieved. The system monitors in real time, and each packaging step will be detected by the infrared monitoring point to detect the product status, including before entering the box, during the box filling and after the box sealing. Combined with the waste rejection system at the back end, the product compliance rate reaches 100%. According to production requirements, the data traceability function can be selected to record every process of packaging in real time and upload it to the server cloud for recording. The data records the filling weight, quantity, timestamp and operator ID of each box in detail, generates an electronic report that meets the requirements of EU GMP Annex 11, and combines with the QR code system to achieve full-link supervision of drugs.

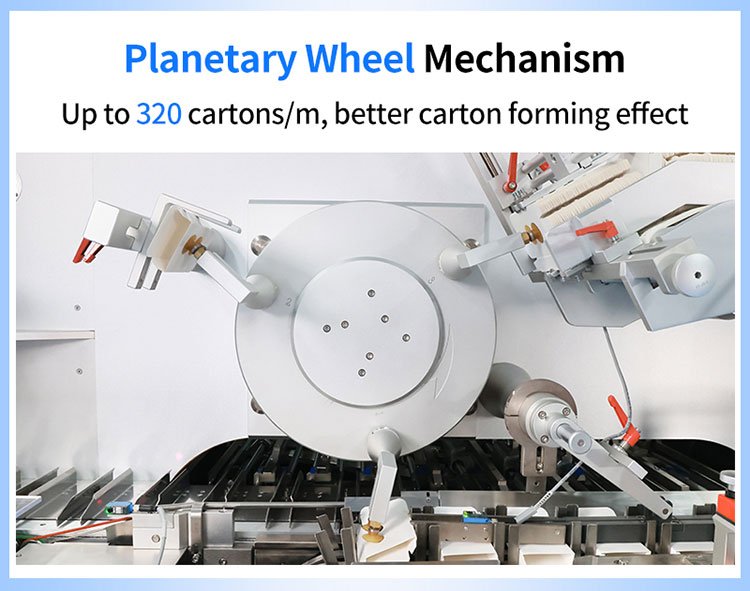

3. The 320W high-speed cartoning machine adopts a rotary four-equal-division double planetary gear box opening mechanism to break the speed bottleneck

Compared with the traditional linear box opening method, due to the inherent structure limited by mechanical inertia, the speed is usually difficult to exceed 200 boxes/minute. The planetary wheel cartoning technology of the RQ-ZH-320W horizontal cartoning machine has achieved a speed far exceeding that of the old models through the following innovations, achieving a stable output of 320 boxes/minute. The four-station cycle runs synchronously, and the four cartoning heads move along the planetary trajectory. Each head independently completes the actions of sucking the box, unfolding the carton, and positioning the carton, which improves efficiency by 160%. Zero-contact and lossless cartoning, using negative pressure adsorption + airflow assisted unfolding technology to avoid mechanical grippers scratching the carton surface (especially when used for high-end pharmaceutical packaging, the effect is more obvious).

4. Intelligent cartoning machine with full servo vibration blanking technology to solve the problem of product box entry

For products that are easy to get stuck, such as tablet blister boards, the RQ-320W uses a Siemens servo vibration feeding system. The multi-axis servo motor is combined with a self-developed PLC driver, and the amplitude is adjustable from 0.01 to 3mm through synchronous gears, and the frequency is programmable from 5 to 200Hz. Intelligent quantity algorithm: The motor controls the upper and lower layers of rotating blades to accurately control the addition of one product each time it rotates. When product stacking is detected (such as two blister plates overlapping), the vibration table automatically switches to high-frequency micro-amplitude mode (50Hz/0.5mm) for separation without jamming. Measured data: When processing 1.2mm thick PVC blister plates, the jam rate dropped from 0.5% of the old equipment to 0.001%. The 320W intelligent cartoning machine also uses a dynamic compensation algorithm: when it is detected that the connection volume is insufficient, the system automatically triggers the feeding mechanism, and the other feeding mechanism will work immediately, and the error compensation response time is only 50ms.

5. German GUK folding machine, high-speed blister plate cartoning machine is durable for 30 years

As a key component of carton packaging, the folding machine adopts German GUK high-end series products and has three core advantages. It has stronger versatility, and the number of folds can be freely set from 1 to 4 folds, achieving a crease position error of ≤±0.03mm. Excellent performance, stable operation is also guaranteed under high-speed cartoning packaging. After strict comparative tests under the same conditions: after 72 hours of continuous operation, the defective forming rate of the GUK folding machine is only 1/20 of that of other similar products.

6. The carton feeding is controlled by servo motor

The carton conveying system of the RQ-ZH-320W carton packaging machine adopts a full servo motor drive solution, which is a revolutionary breakthrough compared to traditional pneumatic/mechanical transmission, and achieves high dynamic response and flexible production. The Siemens synchronous servo control architecture is adopted to achieve a continuously variable speed of 0.2-3.5m/s for feeding the carton, and a repeated positioning accuracy of ±0.02mm (equivalent to an error of 1/4 of a hair), and the system automatically adjusts the center position of the carton. The ZH-320W cartoning machine adopts an intelligent adaptive function to automatically adjust the clamping force according to the weight of the carton (200-750g/m²) to avoid jamming or deformation. Measured data: When processing coated cartons, the servo system reduces the wrinkle rate by 87% compared with the traditional stepper motor solution.

IPv6 network supported

IPv6 network supported