Blister Card Packing Machine

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

| Name | RQ-500G Blister Card Packing Machine |

| Capacity | 5,400 cards/h |

| Max heat sealing size | 500 x 230 mm |

| Max card size | 510 x 230 mm |

| Power supply | 5.4 kW |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

The RQ-BCP-500G Blister Card Sealing Machine: Revolutionizing Packaging Efficiency and Quality

In the ever-changing packaging industry, blister card sealers have become the cornerstone of modern packaging solutions. Blister card sealers are special packaging equipment used to firmly seal capsule or tablet blister sheet products between the front and back of the paperboard, and can accurately align each blister with the hole of the paper card, ensuring that the buyer can clearly see the product and the exquisite appearance of the paper card packaging. With the growing demand for safe, efficient and beautiful packaging in all walks of life, BCP-500G stands out and becomes the first choice for companies seeking to improve packaging operations.

Next, I will talk about the advantages that paper card machines bring to packaging.

Advantages of Blister Card Machine

1. Small footprint and high efficiency: This flat plate blister packing card machine has a smaller footprint than the turntable model, and is a better machine choice, especially when upgrading small factories or old factories. Its advanced functions and high-speed operation capabilities significantly shorten the packaging time compared to manual models, providing a guarantee for high-speed production capacity.

2. Enhanced product protection: RQ-500G solves the problem of blister board fragility and provides it with sturdy and safe paper card packaging, ensuring that the product is protected during transportation and storage, reducing the risk of damage. At the same time, hanging holes can be added to the paper card to facilitate the sale of paper cards in retail stores.

3. Improve aesthetics: A single blister package cannot add merchant information and promotional slogans on the aluminum foil. By blister card packaging, the merchant design that can be clearly printed and customized on the paper card makes the product display more attractive, enhancing consumer appeal and market competitiveness.

Application of RQ-BCP-500G blister card sealer

The 500G developed by our company is specially developed for the blister sheet packaging paper feeding card of the pharmaceutical industry, aiming to solve the problems of easy bending and tearing of blister packaging. It is also an ideal solution for convenient carrying of medicines or health care products packaging, and meets the production standards of cGMP, Europe, the United States, UL, FDA, and etc.

Blister card sealing machines are powerful and widely used. In addition to being widely used in the pharmaceutical industry to package tablets, capsules and medical devices, our company's other paper card machine models can also be used in consumer electronics, cosmetics and personal care, food and beverage industry, hardware and DIY products, toys and games and other fields.

Key Features of the RQ-BCP-500G

The RQ-BCP-500G is equipped with a range of advanced features that set it apart from other packaging machines in the market.These features not only enhance operational efficiency but also ensure the highest quality packaging.

1. Full servo drive motor, precise adjustment

The RQ-BCP-500G blister card sealing machine uses a full servo drive motor to ensure precise and smooth stroke adjustment. This function allows the machine to achieve fast and precise adjustment. When changing different product sizes and packaging requirements, the adjustment can be completed with one click on the touch screen HMI, thereby improving operating efficiency.

2. Fully enclosed design to ensure operator safety

The blister card packaging machine adopts a fully enclosed architecture. When designing, we put safety as the first design factor, and do our best to reduce the exposure of the machine's moving parts, reduce the operator's contact with these parts, and thus reduce the risk of workplace accidents. At the same time, this design also improves the convenience of operation and maintenance.

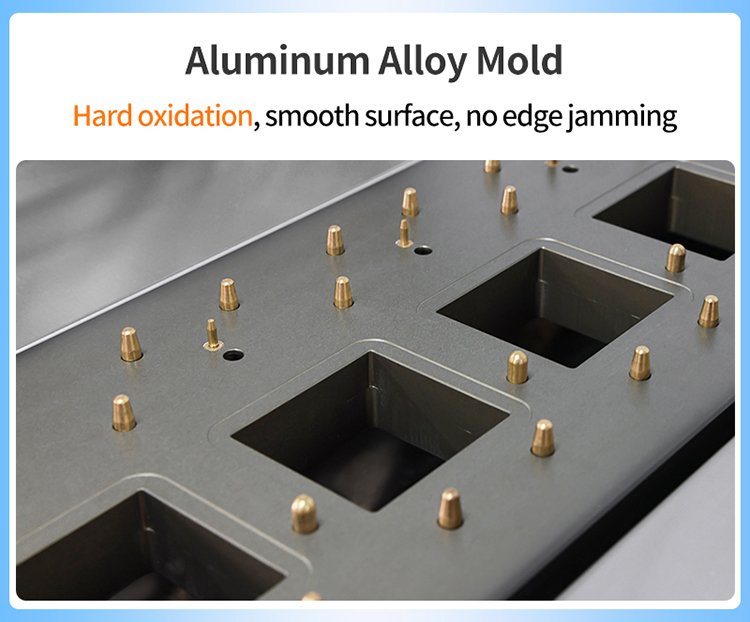

3. High-strength aluminum alloy mold

Durability is essential for high-speed packaging operations. The 500G uses aluminum alloy molds, which have higher hardness and wear resistance than traditional materials, ensuring long-lasting durability even under continuous use.

4. Quick mold change system for enhanced flexibility

Switching between different packaging specifications can be very time-consuming. However, this high speed blister card sealing machine is equipped with a quick-change mold system, which allows operators to change molds in seconds without special tools. This feature significantly reduces downtime and improves production efficiency.

5. One-piece frame, stable structure

A sturdy frame is essential for stable performance. The RQ-BCP-500G adopts an one-piece welded steel frame with excellent rigidity and shock resistance. This design ensures smooth operation even at high speeds.

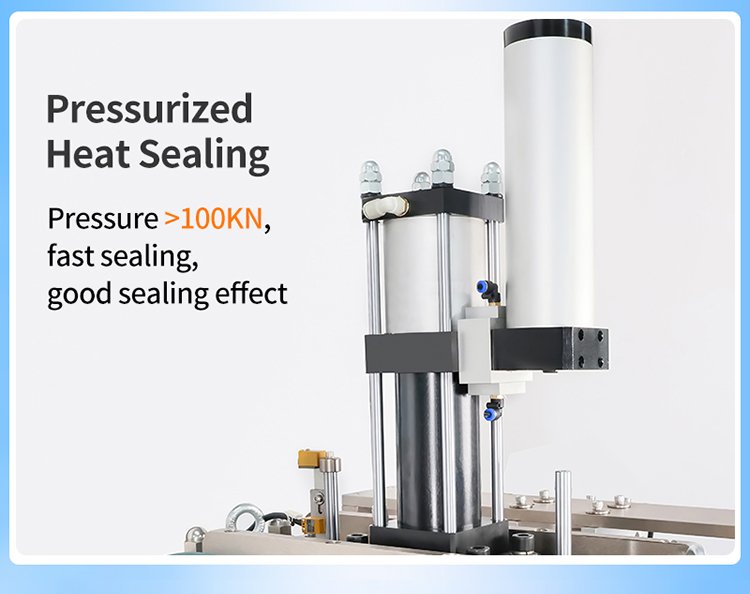

6. Strengthened heat sealing station, excellent pressure resistance

The heat sealing station is a key component of blister packaging. The RQ-BCP-500G blister card packaging machine is equipped with a strengthened sealing mechanism that can withstand high pressure without deformation. This ensures that a safe seal is achieved every time.

7. Safety detection and protection system

In order to prevent accidents and equipment damage, the blister card sealing machine is equipped with an advanced safety detection system. A motion proximity sensor is used to monitor the heat sealing process, and the machine will automatically stop running if an abnormality (such as product misalignment or excessive pressure) is detected. If the heat sealing station does not return to the heat sealing waiting position, the machine mold crawler will not move; the machine will only start to move when the heat sealing station does not understand the waiting time.

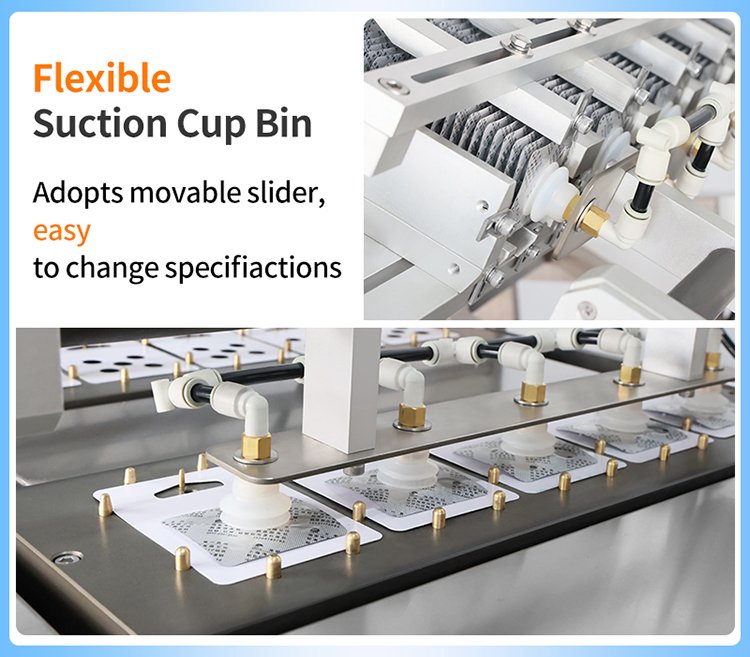

8. Customizable suction cups for various product handling

Different products require different handling mechanisms. BCP-500G can customize suction cup configurations to ensure optimal positioning and suction and placement in various blister card packaging applications.

9. Environmentally friendly materials and cGMP compliant

Sustainability and compliance are becoming increasingly important in the packaging field. This blister card sealing machine uses environmentally friendly materials, and all medicine contact parts are made of SUS 304. It can also be replaced with SUS 316L food-grade stainless steel according to customer customization requirements. It complies with cGMP (current good manufacturing practice) standards and is suitable for drug and food-grade packaging.

10. High-end configuration for unparalleled stability

500G series blister card packing sealing machine is manufactured with high-quality components, including high-precision servo motors, industrial-grade PLC controllers, and durable pneumatic systems. It ensures long-term stability, extremely low maintenance costs and consistent performance even in harsh production environments.

11.The paper blister card packaging machine has a high degree of integration. We have reserved enough I/O interfaces. According to actual customization needs, it is very convenient to connect with capsule filling machines, rotary tablet presses, pharmaceutical blister packaging machines, cartoning machines and other equipment.

IPv6 network supported

IPv6 network supported