Metal Detector Machine

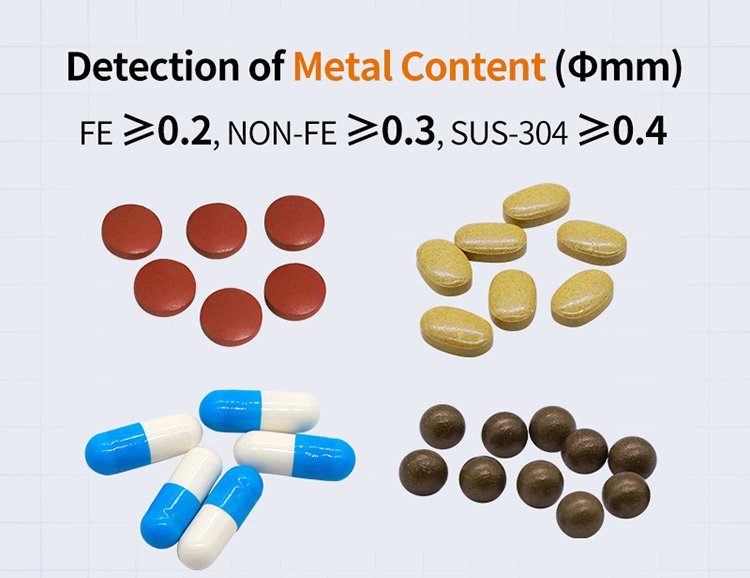

| Product Name | Automatic Metal Detector |

| Precision | Fe <0.2mm, Non-Fe <0.3mm, SUS <0.4mm |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Basic Principle and Function of Metal Detector

Metal detector are automated inspection devices based on the principle of electromagnetic induction, primarily used to identify and remove metal contaminants from products. Their core principle involves detecting the presence of metal through changes in an electromagnetic field. When metal contaminants pass through the detection zone, they disturb the electromagnetic field, which is captured by the detection system. Depending on the type and size of metal in the material, the device can detect ferrous metals ≥ 0.4 mm, non-ferrous metals ≥ 0.8 mm, and stainless steel ≥ 1.0 mm, and reject non-conforming products via saturated rejection.

This high sensitivity detection capability is particularly crucial in the pharmaceutical and food industries. For instance, during the production of tablets and capsules, tiny metal particles may be inadvertently mixed in. Metal detectors pharmaceutical can detect and remove these contaminants, ensuring product purity and safety.

Application Fields and Importance of Metal Detector Machine

Automatic Metal detectors are widely used across numerous industries, including pharmaceuticals, food, and chemicals, particularly when integrated with equipment such as capsule filling machine, rotary tablet press, and counting and packaging production line. In the pharmaceutical medicine industry, metal detectors are critical equipment for ensuring drug safety. For example, during capsule filling, a metal detector can detect potential metal contaminants within the capsules, preventing metal contamination and thereby meeting stringent pharmaceutical safety standards.

With advancements in intelligence and multi-technology integration, the depth and breadth of metal detector applications will continue to expand, providing stronger safeguards for product safety across diverse industries.

Technical Advantages of Metal Detectors

High Sensitivity and Accuracy

The high sensitivity of metal detectors is one of their core advantages. They can detect extremely small metal particles, such as ferrous ≥ 0.4 mm, non-ferrous ≥ 0.8 mm, and stainless steel ≥ 1.0 mm. This capability enables excellent performance when inspecting small-sized products like tablets and capsules. In the pharmaceutical industry, tablets and capsules are typically small with complex internal structures; the presence of metal contaminants can severely impact product quality and safety. Metal detectors accurately detect these minute metal particles, ensuring drug safety and efficacy.

Automation Integration Capability

The automation integration capability of metal detectors allows them to seamlessly integrate with production lines, meeting the demands of high-speed production. Their detection speed ranges from 28 to 98 meters per minute (m/min), accommodating varying production speed requirements. In modern pharmaceutical and food production lines, where speeds are typically high, traditional inspection equipment may fail to keep pace, leading to production interruptions or reduced quality. The high detection speed and automated integration capabilities of metal detectors enable them to work perfectly in concert with other line equipment (e.g., capsule filling machines, rotary tablet presses, counting and packaging lines), facilitating continuous and efficient production.

Furthermore, the automation integration of metal detectors is also evident in their compatibility with other systems. They can integrate with the company's production management systems (such as MES, ERP, etc.), enabling real-time data transmission and sharing. Production managers can monitor the metal detector's operational status in real-time through these systems, access detection data and production reports, and thereby better manage production and control quality. This automation integration capability not only enhances production efficiency but also elevates the company's management level and competitiveness.

Hygienic and Durable Design

The hygienic and durable design of metal detectors enables them to withstand harsh production environments while meeting strict industry standards. The housing is constructed entirely of stainless steel (SUS304/316), offering excellent corrosion resistance and ease of cleaning. In the pharmaceutical and food industries, production environments are often humid with extremely high hygiene requirements. The all-stainless-steel housing prevents equipment rusting and corrosion and ensures surface cleanliness, avoiding product contamination from dirt or bacteria residing on the equipment surface.

Additionally, metal detectors boast a high protection rating of IP65-IP66, effectively preventing ingress of dust, water droplets, etc., into the equipment interior, further enhancing reliability and durability. Relevant test data indicates that metal detectors featuring all-stainless-steel construction and high IP ratings have a service life approximately 30% longer than standard equipment. This durability reduces equipment replacement costs and minimizes production interruptions and quality losses caused by equipment failure.

The design of metal detectors also complies with GMP/HACCP certification requirements, meeting the strict hygiene standards of the pharmaceutical and food industries. GMP (Good Manufacturing Practice) and HACCP (Hazard Analysis Critical Control Point) are vital certification standards in these sectors, imposing rigorous requirements on the hygiene, safety, and reliability of production equipment. Metal detectors are designed and manufactured in strict adherence to these standards, ensuring they effectively prevent product contamination and guarantee product quality and safety during production.

Application of Metal Detectors in Pharmaceutical and Packaging Equipment

Application with Capsule Filling Machine

Metal detectors play a vital role when used with automatic capsule filling machines. As a common pharmaceutical dosage form, capsule production imposes extremely stringent requirements for detecting metal contaminants. During capsule filling machine operation, metal contaminants may enter the capsules due to equipment wear or raw material contamination. The high-sensitivity detection capability of metal detectors effectively identifies ferrous particles ≥ 0.4 mm, non-ferrous particles ≥ 0.8 mm, and stainless steel particles ≥ 1.0 mm, ensuring the purity and safety of capsule products.

Application with Rotary Tablet Press Machine

Metal detectors also offer significant advantages when applied with rotary tablet presses. Rotary tablet press machines are commonly used in the pharmaceutical and food industry to compress powder blends into tablets. During the tablet pressing process, metal contaminants can cause tablet quality issues and potentially damage the press itself. The high-sensitivity detection capability of metal detectors effectively identifies metal contaminants within the tablets, ensuring tablet quality and safety.

Supporting Application in Tablet Capsule Counting Line

Metal detectors serve an important function within counting and packaging lines. These lines are critical in the pharmaceutical and food industries for accurately counting and packaging medicines or food items. During packaging, metal contaminants can cause product quality issues and pose health risks to consumers. The high-sensitivity detection capability of metal detectors effectively identifies metal contaminants in the packaged products, ensuring product quality and safety.

Development Trend of Metal Detectors

With continuous advancements in science and technology, metal detectors are rapidly evolving towards intelligence and multi-technology integration. Continuous upgrades to intelligent functions enable capsule metal detector to better adapt to complex and variable production environments and material characteristics. Integrated with Internet of Things (IoT) technology, metal detectors can achieve remote monitoring and real-time data transmission. Production managers can view equipment operating status and detection data anytime, anywhere via mobile phones or computers, enabling timely problem identification and resolution.

Due to their high sensitivity, accuracy, automated integration capabilities, hygienic and durable design, and intelligent features, metal detectors play an indispensable role in ensuring product safety within the pharmaceutical, food, and other critical industries.

IPv6 network supported

IPv6 network supported