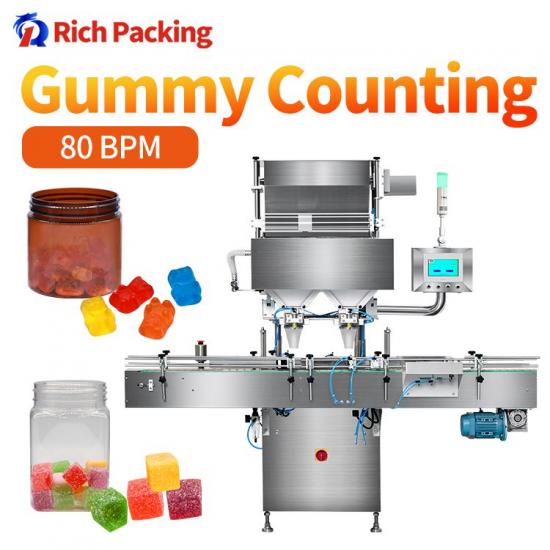

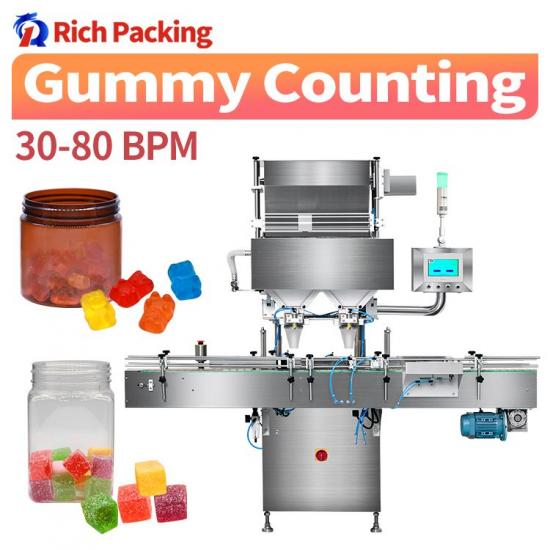

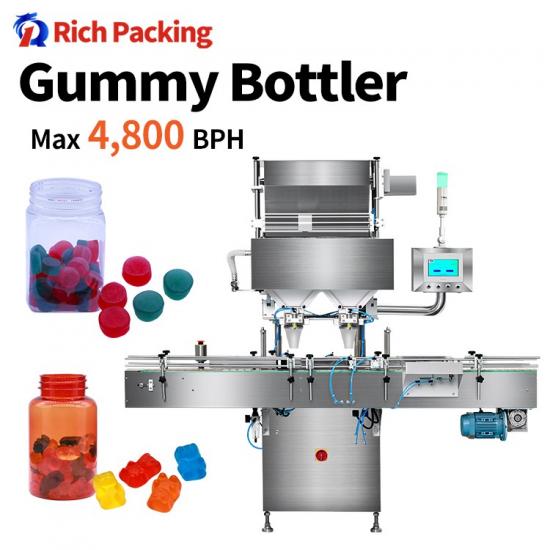

Spercial Gummy Candy Counting Machine By Rich Packing

*** Technical parameter

|

Model |

RQ-DSL-8D |

|

vibration groove tracks |

8 lane |

|

Production capacity |

15-55 bottles/min, base on 60 gummies/bottle |

|

accuracy rate |

>99.97% |

|

Applicable bottle type |

Φ25~75 mm round and square bottle, height ≤240 mm |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

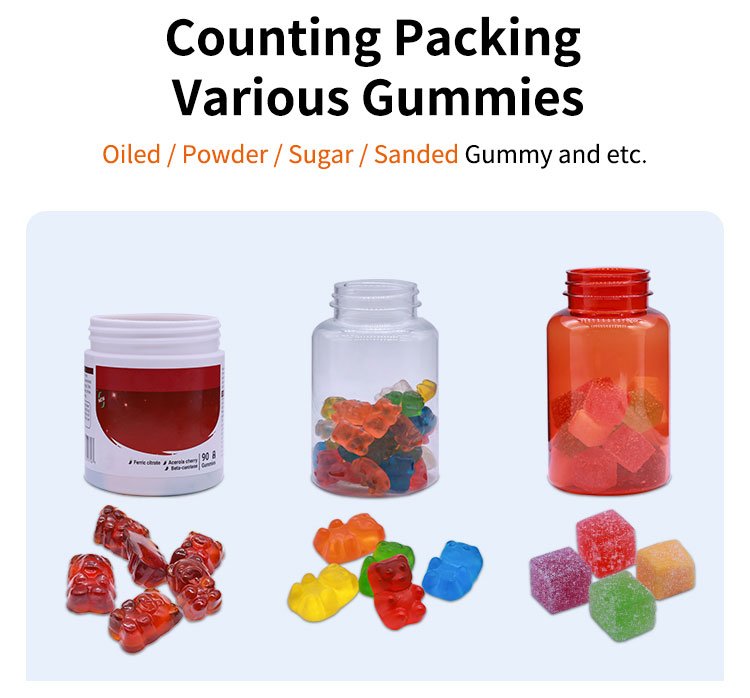

For the continuous innovation of automatic gummies counting machines, the common materials that are hard to count have become a very complete solution mechanically. Since into 2021, the demands for automatic counting machines for sweets candy, and the especially soft candy is growing.

The hardness of this type of soft candy material counting machine is mainly for the viscosity of the material surface, so there is no clear cube shape on the swing hopper. Instead of it often appears in such the way that it may stick in such a way that, once put into the counting ways, it cannot count accurately.

The quantity of counted materials that fall into the counting vibration channel is mostly two or three and or more, but due to the limitation of the counting progress. In this case, the ordinary counting machine automatic will only record it at once. Counting errors are formed, that seriously affects the accuracy of counting cubes and the subsequent production process. The dispensers developed by Rich Packing is a solution for the sticky materials such as the sticky candy and sweets. We Rich Packing specially added the push claws that can be moved horizontally and will move left and right under the hopper, which can break down the stuck materials when moving left and right. The vibrating claw uses the Teflon coating, that is 10 times smoother than the ordinary stainless steel. So our RICH PACKING candy counter machinery will not have these problems, please contact us to purchase.

1. Analysis of Common Problems of Gummy Counting Machine

1.1 Causes of Blockage Caused by Candy Viscosity

During the operation of the gummy counting machine, the viscosity of the candy is one of the key factors that cause the discharge port to be blocked. The viscosity of candy mainly comes from its ingredients and the processing methods during the production process. For example, candies with high sugar and colloid content are more likely to stick together when the temperature and humidity change or when squeezed with other candies. Studies have found that in an environment with a relative humidity of 60%, the viscosity of ordinary hard candies will increase by more than 30%, which makes it easy for candies to accumulate in the silo and discharge port, leading to blockage.

In addition, the shape and size of the gummies will also affect the blockage. Irregularly shaped candies are more likely to get stuck or accumulate with each other when passing through the counting machine. For example, when some special-shaped candies pass through the oscillation channel, their edges and protruding parts are easy to contact with other candies or equipment, and the probability of blockage is about 40% higher than that of round candies. Candy size differences can also cause blockage. Candies that are too large are difficult to pass through the standard size discharge port smoothly, while candies that are too small are easy to accumulate in the gaps of the equipment.

From the perspective of equipment, the materials and designs of the silo, oscillation channel and discharge port of the traditional counting machine are also insufficient. The silo and channel made of ordinary stainless steel are easy to adhere to the candy and difficult to clean. In addition, the discharge port size of the traditional counting machine is fixed and cannot be adjusted according to the size of the candy, which is also one of the common causes of blockage. According to industry statistics, the blockage failure rate of the traditional counting machine due to the stickiness of the candy is as high as more than 20%, which seriously affects the production efficiency and equipment life.

2. Features of Guangdong Rich Packing Candy Counting Machine

2.1 Advantages of the silo stirring system

The silo stirring system of Guangdong Rich Packing Candy Counting Machine is one of the key innovations to solve the problem of candy stickiness. By setting a stirring rod in the silo, the candies that stick together can be effectively broken up. The design of this system is based on an in-depth study of the physical properties of candy. The speed and angle of the stirring rod are accurately calculated to ensure that the candy is not damaged. Under the premise of achieving efficient separation, the experimental data shows that the stirring system can make the candy separation rate reach more than 95%, significantly reducing the risk of blockage caused by the stickiness of the candy. Compared with traditional counting machines, the Guangdong Rich Packing candy counting machine with a silo mixing system has a blockage failure rate reduced by about 70% under the same working conditions. In addition, the system also has an automatic sensing function, which can automatically adjust the mixing speed according to the flow and viscosity of the candy, further improving the intelligence level and adaptability of the equipment.

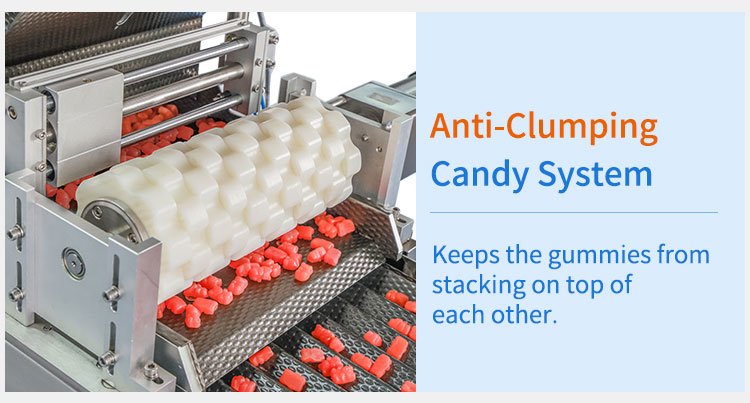

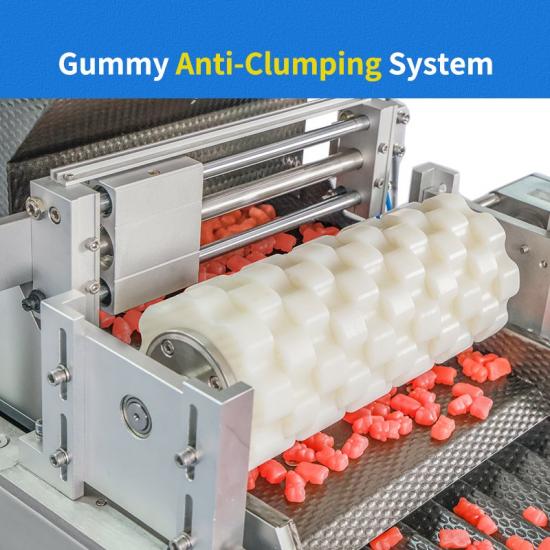

2.2 Function of the anti-stacking system

The anti-stacking system of the Guangdong Rich Packing candy counting machine is optimized for the shape and size characteristics of the candy. The system uses customized rollers to accurately match the size and shape of the candy, effectively preventing the candy from stacking when entering the counting oscillation channel. Studies have found that the stacking of candies in the oscillation channel is one of the important causes of blockage, especially when dealing with irregular-shaped candies, the probability of stacking is higher. Guangdong Ruiqi's anti-stacking system reduces the stacking rate of candies to less than 5% through precise roller design and layout, greatly improving the operating efficiency and stability of the counting machine. Compared with ordinary counting machines, this system not only reduces the occurrence of blockage failures, but also improves the counting accuracy of candies, ensuring the quality and consistency of the products. In addition, the anti-stacking system also has good adjustability and can adapt to different types and specifications of candies to meet diverse production needs.

3. Gummy counter material and design improvement

3.1 Application of Teflon raindrop plate

Guangdong Rich Packing candy counting machine has made important innovations in equipment materials and adopted Teflon raindrop plate. Teflon has extremely low surface energy, and it is difficult for candies to adhere to its surface. Experiments show that the amount of candy adhesion is reduced by more than 90% compared with ordinary stainless steel parts using Teflon-coated parts. The application of this material not only effectively solves the problem of inaccurate counting of candies due to stickiness on the equipment, but also greatly facilitates the cleaning of the equipment. After processing sticky candies, the traditional counting machine takes an average of more than 30 minutes to clean, while Guangdong Ruiqi's Teflon raindrop plate design shortens the cleaning time to less than 5 minutes, significantly improving the equipment's use efficiency and production continuity.

3.2 Enlarged discharge port design

In order to solve the problem that large candies are easily blocked at the discharge port, Guangdong Rich Packing adopted a design of enlarging the polytetrafluoroethylene discharge port. The polytetrafluoroethylene material itself has good anti-stickiness, and increasing the size of the feed port can better adapt to candies of different sizes. After actual testing, the enlarged feed port can smoothly pass large candies with a diameter of more than 3 cm, and the probability of clogging is reduced to less than 1%. In addition, the design of the feed port also takes into account the flow characteristics of gummies. By optimizing the shape and angle of the feed port, the passing efficiency of candies is further improved, ensuring the stable operation of the counting machine. This improvement not only solves the common clogging problem of traditional counting machines, but also improves the overall performance of the equipment, enabling it to better meet the diversified needs of candy production.

4. Supporting services and after-sales support

4.1 Configuration and technical information

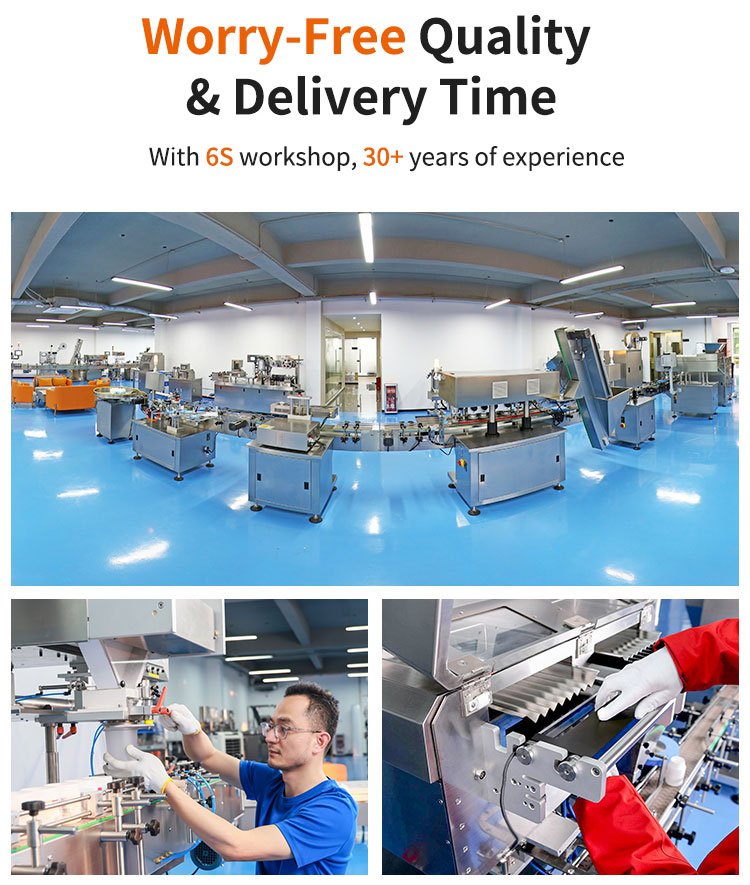

Guangdong Rich Packing provides comprehensive and high-quality supporting configurations and technical information for candy counting machines to ensure that users can use the equipment efficiently and safely and give full play to its performance. First of all, the machine configuration is all world-famous brand electrical appliances. These electrical appliance brands have a good reputation and reliable performance in the industry, with low failure rate and long service life, which can effectively guarantee the stable operation of the counting machine. Like as, the well-known brand motors used have the characteristics of high efficiency and low energy consumption. Compared with ordinary motors, they can save about 15% of energy consumption. At the same time, their durability extends the average trouble-free operation time of the equipment by more than 30%, greatly reducing the downtime and maintenance costs caused by equipment failure.

In addition, Guangdong Rich Packing provides users with a full set of user technical manuals, which are detailed and cover key information such as the equipment's operating procedures, parameter settings, daily maintenance, and common troubleshooting. The technical manual uses pictures and texts to enable users to understand and master the use of the equipment more intuitively. For example, in the operation process section, through detailed step-by-step instructions and clear schematic diagrams, even operators who use the equipment for the first time can master the operating essentials in a short time, shortening the initial commissioning time of the equipment by about 40%. In terms of daily maintenance, the manual provides specific maintenance cycles and operating guidelines to help users establish a scientific equipment maintenance system, extend the service life of the equipment, and reduce the long-term use cost of the equipment.

In order to further enhance the user experience, Guangdong Rich Packing also provides video materials on daily maintenance, cleaning, and use. These videos show the various operation links and maintenance points of the equipment in a vivid and intuitive way, so that users can learn and master relevant skills more intuitively. For example, in the cleaning video, it is shown in detail how to properly disassemble and clean the key components of the equipment, including the Teflon raindrop plate and the feed port, to ensure that users can follow the correct steps to avoid equipment damage due to improper cleaning. By watching these videos, users' learning efficiency has increased by about 50%, and they can master the maintenance skills of the equipment more quickly, thereby better ensuring the normal operation of the equipment.

4.2 Global Service Network

Guangdong Rich Packing has established a complete global service network and is committed to providing timely, efficient and professional after-sales service to users around the world. Globally, Guangdong Rich Packing has multiple service centers and maintenance sites, which are widely distributed and can quickly respond to users' after-sales needs. For example, in major markets in Europe, America and Asia, Guangdong Rich Packing has established localized service centers, which are equipped with professional technicians and sufficient spare parts inventory. They can arrive at the site for maintenance services within 24 hours after receiving the user's repair report to ensure the shortest downtime of the equipment. This efficient response speed is at the leading level in the industry, greatly reducing the production losses suffered by users due to equipment failures.

In addition to the localized service center, Guangdong Rich Packing has also established a globally unified service standard and quality monitoring system. All service personnel have undergone rigorous professional training and have rich experience in equipment repair and maintenance. During the repair process, service personnel strictly follow the standardized operating procedures to ensure the quality of repair. For example, after the repair is completed, the service personnel will conduct a comprehensive inspection and debugging of the equipment to ensure that the various performance indicators of the equipment meet the factory standards. At the same time, Guangdong Rich Packing will also conduct quality return visits for maintenance services, collect user feedback, and continuously optimize service processes and quality. User satisfaction with after-sales service is as high as more than 98%, which fully reflects the efficiency and professionalism of Guangdong Ruiqi's global service network.

Guangdong Rich Packing also provides global local door-to-door services, and this service model further enhances the user experience. No matter where the user is, as long as the equipment fails or needs maintenance, Guangdong Rich Packing can arrange professional technicians to provide door-to-door services. This service method not only saves users' time and energy, but also avoids the risk of damage that may occur during equipment transportation. For example, for some large candy production companies, equipment downtime means huge economic losses. Guangdong Ruiqi's local door-to-door service can restore the normal operation of the equipment in the shortest time and help companies reduce losses. In addition, the door-to-door service can also provide users with on-site technical training and guidance to help users better master the use and maintenance skills of the equipment, improve users' independent maintenance capabilities, and further ensure the long-term stable operation of the equipment.

5. Summary

Guangdong Rich Packing has successfully developed an efficient and stable candy counting machine through a series of innovative designs and technical improvements to address the common stickiness-induced blockage problem of candy counting machines. Its silo mixing system, anti-stacking system, Teflon raindrop plate, and increased polytetrafluoroethylene feed port and other improvement measures have effectively solved the blockage problem of traditional counting machines from the perspectives of candy separation, stacking prevention, equipment anti-stickiness and adaptability, and significantly improved the operating efficiency and stability of the equipment. At the same time, it uses world-famous brand electrical configurations, provides detailed technical information and video tutorials, and establishes a complete global service network to provide users with all-round support and guarantee. The combination of these innovations and services not only improves the automation level and product quality of candy production, but also brings significant economic benefits and production convenience to candy manufacturers, demonstrating Guangdong Ruiqi's technical strength and market competitiveness in the field of candy counting machines.

IPv6 network supported

IPv6 network supported