NJP 800C Capsule Filling Machine

*** Technical parameter

|

Production capacity |

48,000 pcs/h |

|

Power |

380/220V 50Hz |

|

Vacuum |

120m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule 99.9% Full capsule 99.8% |

|

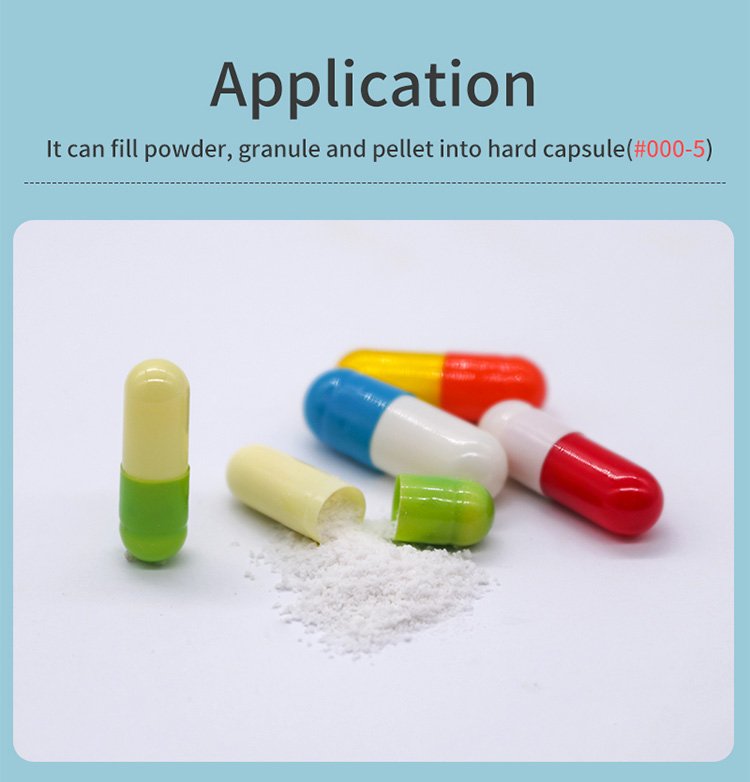

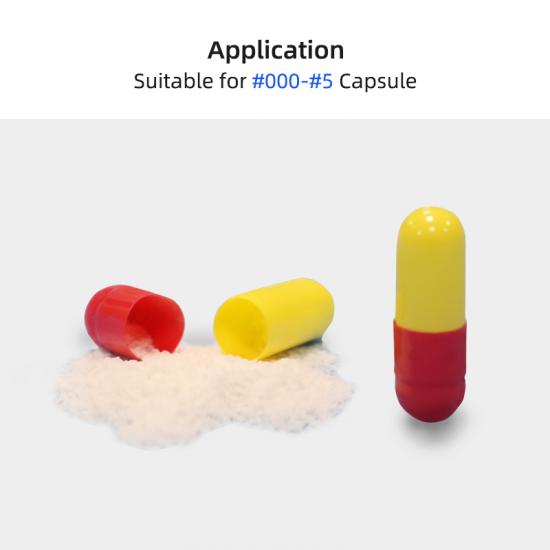

Applicable capsule |

000,00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Auto Capsule Filling Machine: The Definitive Guide to Maximizing Efficiency with the NJP-800C

Introduction: The Critical Role of Mid-Sized Automation in Modern Pharma

In the highly regulated world of pharmaceutical and nutraceutical manufacturing, efficiency, precision, and compliance are non-negotiable. This balance is precisely where the auto capsule filling machine shines. Specifically, the RICH PACKING NJP-800C model is engineered to be the workhorse of a cGMP-compliant facility, offering a compelling blend of advanced technology and cost-effective operation.

This NJP-800C guide serves as an essential resource for the production managers, quality assurance personnel, and procurement teams. We will deep-dive into the technical advantages, operational benefits, and long-term value of choosing the NJP 800 capsuling machine for your high-quality, mid-to-high volume capsule production needs.

Section 1: The Strategic Advantage of the NJP-800C in the Mid-Market

The NJP 800 filling capsule machine is strategically positioned to serve businesses that require consistent, high-quality output without the prohibitive cost and space requirements of top-tier mega-machines.

1.1 Optimizing Capacity: The Sweet Spot of Production

While "high-speed" often implies 150,000+ capsules/hour, the NJP-800C provides a robust and reliable output—typically around 48,000 capsules per hour—which is the "sweet spot" for many applications:

For CMOs: This capacity is ideal for running multiple customer batches per shift, maximizing the revenue potential of the line without sacrificing quality or requiring overly complex material handling.

For Specialty Pharma: It efficiently handles high-value, niche products where raw material cost dictates a focus on yield and precision over sheer volume.

For Market Entry: It serves as a perfect stepping stone for companies transitioning from semi-automatic systems, offering a major leap in automation and precision without overcapitalizing.

1.2 The Power of the Fully Automatic Capsule Filling Machine

The NJP-800C operates as a capsule filler fully automatic, meaning it handles every stage of the encapsulation process with minimal operator intervention:

1. Capsule Feeding and Separation: Automatic orientation and vacuum separation of empty capsules.

2. Powder Dosing: Precise tamping and filling.

3. Capsule Sealing and Ejection: Locking the filled capsules and ejecting the finished product.

4. Rejecting: Automatic detection and removal of un-separated or unfilled capsules.

Section 2: Technical Excellence: Achieving Impeccable Dosing Precision

The core value of any auto capsule filling machine lies in its ability to deliver an exact dosage consistently. The NJP-800C excels through its advanced engineering focused on precision.

2.1 The Tamping Pin Dosing Principle

The NJP series utilizes the time-tested and reliable tamping pin dosing principle.

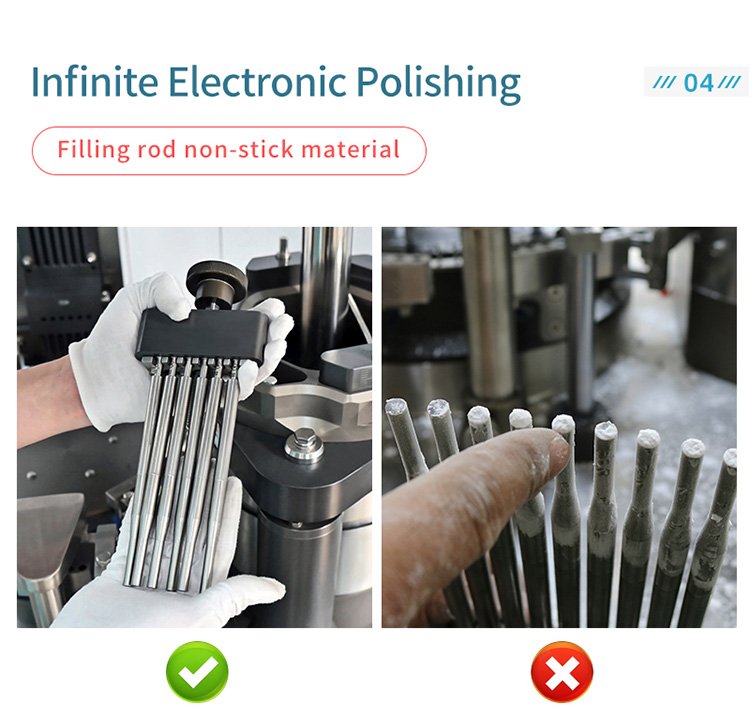

How it Works: The system uses a multi-stage process where powder is collected in a dosing disc (metering plate) and then gently compressed by a set of tamping pins. This creates a highly uniform "powder plug" which is subsequently ejected into the empty capsule body.

Precision Advantage: This method is far superior to simple volumetric filling for pharmaceuticals. It ensures a stable, consistent powder bulk density within the plug, allowing the powder capsule filling machine to maintain a weight variation (Relative Standard Deviation) often below 3%. This high precision is crucial for products with narrow therapeutic indices.

2.2 Handling Diverse Powder Characteristics

Not all pharmaceutical powders behave the same. Some are fine and highly fluid, others are coarse, and some are cohesive or hygroscopic.

Adaptability: The automatic NJP capsule machine can be optimized with specialized dosing units (e.g., vacuum feeders, augers) to handle difficult materials. The adjustable tamping depth allows operators to fine-tune the compression ratio, ensuring accurate filling for low-density or high-density powders alike.

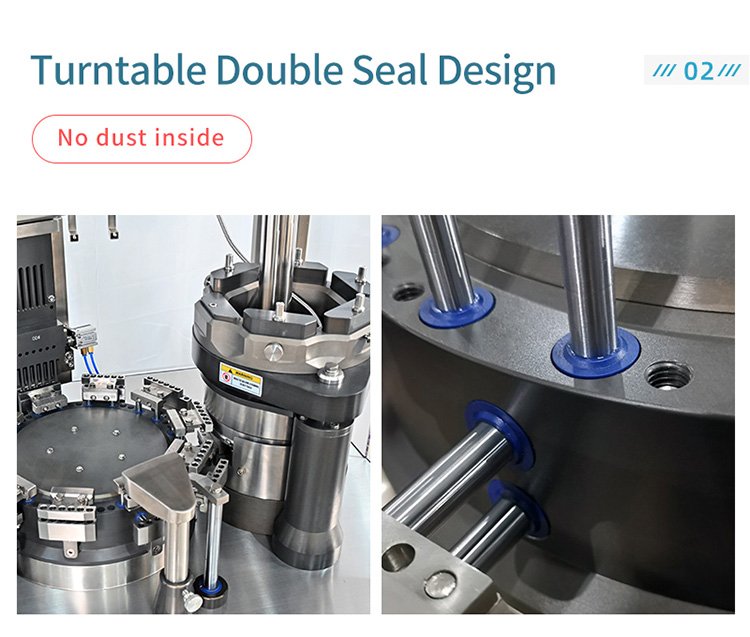

To prevent cross-contamination: The machine adopts a fully enclosed filling station design and an upgraded mold cleaning system to minimize dust escape. A low-dust environment is very important for cleanrooms in the pharmaceutical or nutritional supplement industries.

Section 3: Engineering for Compliance and Reliability (E-E-A-T Focus)

In the pharmaceutical sector, machine construction is inseparable from product quality and regulatory compliance. The NJP-800C is built to meet global cGMP standards.

3.1 cGMP-Compliant Design and Construction

Materials: All parts that come into contact with the product (contact parts) are manufactured from AISI 316L stainless steel, offering superior resistance to corrosion and chemical agents. Non-contact areas utilize $\text{304}$ stainless steel. This material selection ensures the machine adheres to the highest hygienic standards.

Modular design and ease of use: The modular design of the capsule dispensing, ingredient filling, and capsule locking stations facilitates quick cleaning and inspection. Tool-free, quick-release components minimize downtime during product changeovers, with mold changes for all of the above stations taking only 14 minutes.

3.2 The Importance of Validation (IQ/OQ/PQ)

Expertise (E) and Trustworthiness (T) in the pharma machinery domain are demonstrated through thorough validation support.

Documentation: RICH PACKING provides full Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) documentation packages. This crucial support significantly simplifies the customer's internal validation process, accelerating regulatory approval and minimizing time-to-market.

Control System: The machine's control system features a sophisticated HMI (Human-Machine Interface) that includes batch record printing, fault diagnostics, and multi-level password protection, adhering to FDA 21 CFR Part 11 principles of data integrity.

Section 4: Operational Benefits and Total Cost of Ownership (TCO)

Choosing the fully automatic capsule filling machine is an investment that must be justified by its TCO. The NJP-800C delivers exceptional value through efficiency and support.

4.1 Maximizing Yield and Minimizing Waste

Precision filling directly translates to raw material savings, especially with costly Active Pharmaceutical Ingredients (APIs).

Efficient Separation: The highly reliable vacuum separation system minimizes the rejection rate of split or unseparated capsules, ensuring that only quality product proceeds to the next stage.

Automatic Rejection: The machine automatically detects and ejects incomplete or faulty capsules, maintaining product integrity and maximizing the batch yield—a significant factor in profitability.

4.2 Comprehensive Global Support and Low Maintenance Burden

A high-quality auto capsule filling machine should come with world-class support. The manufacturer's commitment post-sale drastically affects the machine's uptime and long-term TCO.

Global On-Site Service: RICH PACKING's offering of global on-site service, including installation, commissioning, and training, ensures that the customer's team gains the necessary Experience (E) to run the machine optimally from day one.

Warranty and Parts: A 3-year warranty on components and free 1-year wearing parts significantly de-risks the initial investment, demonstrating the manufacturer's Trustworthiness (T) in their product quality.

Logistics Simplified: Services like DDP and DDU shipping streamline the procurement process for international buyers, reducing logistical headaches and ensuring predictable delivery timelines.

Section 5: Seamless Integration into the RICH PACKING Packaging Line

The NJP-800C is not a standalone unit; it is designed to be the central automation hub of a complete packaging line.

5.1 Capsule Production End-to-End Solutions

For ultimate efficiency, the automatic encapsulation machine must integrate perfectly with downstream equipment. RICH PACKING offers a full suite of complementary machinery:

Capsule Polishing and Dedusting: Connected directly after the filler to remove residual powder.

Automatic Capsule Counting Machine: For precise batch counting into bottles.

Blister Packing Machine and Cartoning Machine: For creating retail-ready packs.

This single-source supplier ensures full compatibility, simplified service, and maximum throughput across the entire production chain.

5.2 Future-Proofing Your Investment

Choosing a reliable platform like the capsule filler machine njp 800 guarantees scalability. As production volumes increase, the machine's design allows for potential upgrades and module additions, ensuring the initial investment remains viable for years to come.

Conclusion: The Smart Choice for Precision and Profitability

For any pharmaceutical or nutraceutical company seeking to upgrade its production capabilities with a reliable, cGMP-compliant, and cost-effective solution, the RICH PACKING NJP-800C auto capsule filling machine stands out as the definitive choice.

By offering high-speed automation (48,000 caps/hr), superior filling powder capsule machine precision, and comprehensive global support (3-year warranty, on-site service), the NJP-800C doesn't just fill capsules; it stabilizes your production workflow and secures your market advantage.

Traditional capsule filling machine often use mechanical or gravity discharge systems, which can present some challenges when handling materials with poor flow. Materials with poor fluidity are often prone to agglomeration, blockage or gaps during the unloading process, resulting in uneven filling and inaccurate medecine dosage, thus affecting product quality.

The NJP-800C capsule filling machine introduces pneumatic blanking technology, which uses air pressure to drive the material blanking process. This innovative technology brings multiple advantages:

1. Improve the filling effect of materials with poor fluidity: Pneumatic unloading can guide the material into the filling pipe more evenly and stably, ensuring uniform filling regardless of the difference in fluidity of the material. This is very beneficial for handling pharmaceuticals or nutraceuticals with different powder properties.

2. Reduce caking and clogging: Due to the pneumatic unloading method, the flow of materials in the unloading pipe is more continuous and smooth, reducing the risk of caking and clogging. This helps improve equipment stability and reduces the need for maintenance and cleaning.

3. Improve production efficiency: The filling process is more stable and controllable, reducing the scrap rate and improving production efficiency. This is especially important for pharmaceutical and nutraceutical companies, which need to efficiently meet market demands.

The NJP-800C capsule filler brings significant benefits to the pharmaceutical and health care products industries with its innovative pneumatic unloading technology. This technology improves the filling effect of materials with poor fluidity, reduces the scrap rate, improves production efficiency, and reduces drug waste. As a modern solution, the NJP-800C capsule filling machine will continue to play a key role in the pharmaceutical industry, ensuring high-quality capsule products.

IPv6 network supported

IPv6 network supported