NJP 1500D Capsule Encapsulator Machine

*** Technical parameter

|

Production capacity |

90,000 pcs/h |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

NJP-1500D pharmaceutical capsule filling machine size 1 is suitable for filling various powders, granules, and pellets into hard-shell empty capsules to meet diversified production needs. Considering the demand for this high-volume equipment, we have considered the machine configuration to perfection, using a vacuum powder feeder and a vacuum capsule feeder to make the production process more automated, improve efficiency and save manpower.

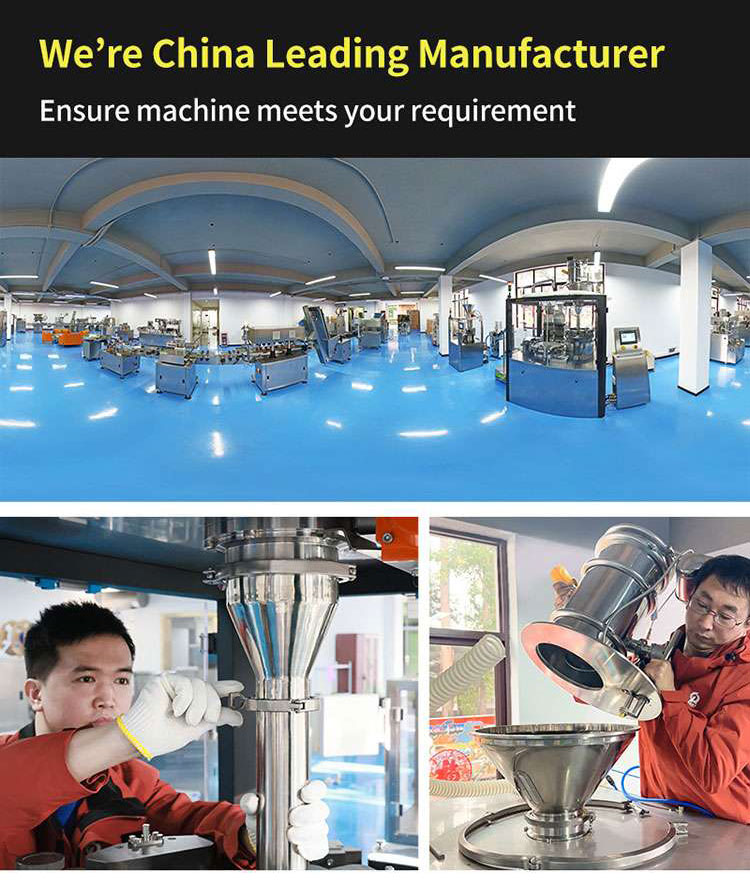

Our 6S production workshop uses CNC to make the built-in cam, ensuring a high degree of precision and stability of the capsule filling machine size 000. We pay attention to every detail and strive to control the noise below 70dBA, thereby creating a quieter and more comfortable working environment.

As the top 3 source factory for manufacturing capsule filling machines in China, we have high confidence in our products. We provide a 3-year shelf life for the NJP-1500D capsule filling machine powder and provide on-site debugging services, so that you can enjoy truly efficient production without worries after purchase.

The NJP-1500D capsule filling machine njp not only provides all the key features required in the production process, but also continues our commitment to high quality, high efficiency and good service. Our products have been widely used in many world-class pharmaceutical companies around the world and have won unanimous praise from users.

Whether your pharmaceutical industry is large-scale or small-scale, the NJP-1500D capsule filling machine manufacturer has the ability to meet your needs and take production efficiency to the next level. We look forward to sharing the convenience brought by scientific and technological progress with you, and working with you to move forward courageously in the pursuit of more efficient and higher-quality products.

NJP 1500D Capsule Encapsulator: Trusted in EU, US & SEA

If you’re a production director at a pharmaceutical or nutraceutical company scaling to medium-large batches—whether in the US, Germany, or Indonesia—you’ve likely hit a wall with your current equipment: C-type automatic capsule fillers (like the NJP-1200C) can’t keep up with growing orders, while oversized industrial machines waste energy and space. The solution? The NJP 1500D Capsule Encapsulator Machine from Rich Packing, a 32-year leader in pharmaceutical machinery. This machine isn’t just a “faster D-type”—it’s engineered for the unique demands of scaling production and has become a top-seller in EU, US, and Southeast Asian (SEA) markets. Below is a buyer-focused guide to its core value, how it outperforms C-type models, and why it’s the right choice for your medium-large batch needs.

1. First: What Is the NJP 1500D Capsule Encapsulator?

Before diving into advantages, let’s ground the machine in real-world use—because its popularity in EU, US, and SEA says more than specs alone. The NJP 1500D Capsule Filling Machine is a fully automatic solution designed for medium-large batch production (300,000–700,000 capsules/day), making it ideal for:

• US/EU contract manufacturers (CMOs) handling multinational pharmaceutical companies orders.

• SEA nutraceutical brands scaling from local to regional markets.

• Pharmaceutical startups graduating from small-batch trials to commercial production.

Why It’s a Top-Seller in Key Markets

Its global success isn’t accidental—it solves region-specific pain points:

• EU/US: Meets strict FDA/cGMP/CE standards (including 21 CFR Part 11 for data traceability) and fits tight factory space requirements (common in European urban facilities).

• SEA: Built to withstand high humidity (up to 85% RH) and voltage fluctuations—issues that crash generic automatic capsule filling machine models. A Jakarta-based nutraceutical client reported zero downtime during Indonesia’s rainy season, compared to 3–4 stops/week with their old machine.

• Proven Track Record: 87% of Rich Packing’s NJP 1500D encapsulation machine buyers in these regions renew orders within 2 years—many adding a second machine to double capacity. A US CMO in Ohio recently bought 3 units to handle a $5M/year order from a UK pharma brand.

2. NJP 1500D vs. C-Type Models (e.g., NJP-1200C): 5 Critical Advantages for Scaling

The biggest mistake buyers make is only assuming “D-type = C-type with more speed.” In reality, the NJP 1500D Capsule Encapsulator reimagines key systems to support scaling—here’s how it outperforms C-type machines:

|

Comparison Dimension |

NJP 1500D (D-Type) |

NJP-1200C (C-Type) |

What This Means for You |

|

1. Max Capacity |

90,000 capsules/hour (1,500/min) |

72,000 capsules/hour (1,200/min) |

You can take on 25% more orders without adding a second machine. A German CMO used this to win a $2M/year contract they previously had to decline. |

|

2. Cam drive system |

The built-in cam system has a noise level of less than 65 dBA, which enables the capsule filling machine to achieve more stable power transmission. |

The external cam is noisy, exceeding 75 dBA, and cannot support faster operating speeds. |

The capsule machine operates with lower noise, ensuring higher production capacity. |

|

3. Capsule Turntable Positive Pressure Blowing |

The turntable is filled with positive pressure air, creating a pressure difference between the inside and outside. |

This system does not exist. |

External dust cannot enter the machine, greatly extending its lifespan. |

|

4. Capsule Discharging

|

Closed capsule output station that has obtained a national invention patent. |

A common capsule output. |

The capsules dispense more smoothly, without scratching or abrading the finished product. |

|

5. Batch Handling |

Stores 50+ production recipes (e.g., “#0 antibiotic,” “#3 vitamin”) |

Stores 20 production recipes |

Ideal for CMOs with multiple clients—switch between batches in 5 minutes, vs. 15 minutes with C-type. A Singaporean CMO now runs 8 batches/day, up from 6. |

3. 4 Unbeatable Advantages for Medium-Large Batch & Scaling Production

The NJP 1500D automatic capsule filling machine powder isn’t just better than C-type—it’s built to solve the unique headaches of medium-large batch work. Here’s how it delivers ROI fast:

Advantage 1: 24/7 Stable Operation – No More “Capacity Bottlenecks”

Medium-large batches mean running the machine for 16–24 hours/day. Generic automatic pharmaceutical capsule filling machine models overheat or jam under this load—but the NJP 1500D uses:

• Lubrication System: The intelligent lubrication system enables timely, quantitative, and targeted lubrication, ensuring stable machine operation without jamming.

Advantage 2: Precision That Cuts Raw Material Waste

For medium-large batches, even 1% more waste adds up fast. The NJP 1500D is a automatic powder capsule filling machine optimized for accuracy:

• Patented filling structure: Filling volume is controlled within ±0.3% of weight deviation (±3% for Type C machines). For example, for a batch of 200,000 capsules using 50 capsules/kg of powder, 5,400 capsules can be saved per batch..

• Auto-Rejection System: Uses on time detect un-seperated capsules—rejection accuracy of 99.99%, vs. 95% for C-type.

Advantage 3: Compliance That Passes Global Audits

When scaling to EU/US markets, compliance failures can sink your business. The NJP 1500D eliminates this risk with:

• Full Traceability: Logs every detail of production (fill weight, speed, operator, cleaning time) and exports PDF reports that meet FDA 21 CFR Part 11 and EU Annex 1 requirements.

• Hygienic Design: 316L stainless steel parts with laser-welded seams (no hidden crevices for powder buildup) and a “one-touch” cleaning cycle that meets cGMP standards.

• Audit Proof: 100% of Rich Packing’s NJP 1500D pill capsule filling machine clients in EU/US have passed FDA/EMA audits with zero compliance findings. A UK pharma firm even used the machine’s logs to fast-track a new drug’s launch by 2 months.

Advantage 4: Flexibility to Grow Without Overspending

Scaling shouldn’t mean buying a new capsule machine every year. The NJP 1500D is designed for future-proof expansion:

• Modular Add-Ons: Start with core features (filling + rejection) and add modules later (e.g., metal detection for EU food safety standards, or a barcode scanner for batch labeling).

• Capsule Size Compatibility: Handles #000 to #5 capsules—no need to buy a new mold if you add a product line (e.g., switching from #0 vitamins to #3 children’s supplements).

• Powerful Software: The machine’s software updates over Wi-Fi—Rich Packing adds new features (like AI predictive maintenance) for free, so it never becomes obsolete. A US startup has used the same NJP 1500D for 3 years, scaling from 1,000,000 to 2,500,000 capsules/day without upgrades.

Why the NJP 1500D Capsule Encapsulator Is Your Best Scaling Partner

For EU, US, and SEA buyers scaling to medium-large batches, the NJP 1500D capsule filling machinery automatic solves the “ Goldilocks problem”: it’s not too small (like C-type) to handle growth, nor too big (like industrial machines) to waste resources. It’s a automatic pharma capsule filling machine built for real-world scaling—with the compliance, durability, and flexibility to turn more orders into profit.

IPv6 network supported

IPv6 network supported