DPP-270max High Speed Packing Blister Machine

*** Technical parameter

| model | DPP-270MAX |

| production capacity | 11,200 blisters/h |

| total power | 7.0kW |

| power supply | 380V/220V/50Hz |

| machine weight | 2600 kg |

| Dimensions | 3500*740*1680 mm |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Blister Packing Machine: 5 Advantages of Rich Packing’s DPP-Max Series to End Maintenance Frustration

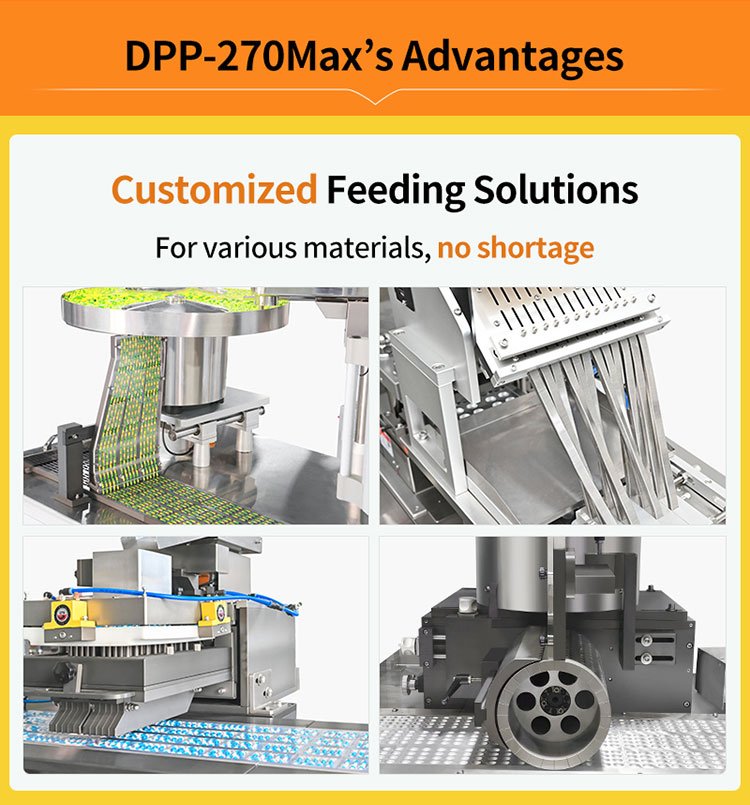

For pharmaceutical and nutraceutical manufacturers, a unreliable packing blister machine can turn daily operations into a cycle of frustration: hours wasted on cleaning hard-to-reach corners, half a day lost to mold changes, and endless adjustments just to align forming and sealing working station. Traditional blister packaging machine designs often prioritize speed over usability, leaving teams stuck with cumbersome maintenance, frequent downtime, and rising labor costs. If you’re tired of letting your capsule tablet packing machine dictate production schedules, Rich Packing’s newly upgraded DPP-Max series is engineered to solve these pain points—redefining efficiency, ease of use, and reliability for modern pharmaceutical packaging.

Backed by Rich Packing’s 32 years of expertise in pharmaceutical machinery, the DPP-Max series (including the high-performance DPP-270Max model) has quickly become a standout at industry expos and customer sites worldwide. Its science-driven design addresses the root causes of maintenance headaches, making it a top choice for manufacturers seeking a tablet blister packing machine or capsule packing machine that balances speed (up to 11,200 plates/h) with hassle-free operation. Below, we break down the 5 key features that make this machine a game-changer.

1. Balcony-Style Large Platform Design: No More Cleaning Dead Zones

The first challenge with most traditional models is inaccessible workspace—narrow gaps, uneven surfaces, and hidden corners trap powder and residue, turning cleaning into a 2-hour daily chore. The DPP-Max series solves this with an ergonomically optimized balcony-style large platform:

• Scientific Design Principle: The platform’s 3500×740mm flat, unobstructed surface follows human engineering guidelines, allowing operators to reach every area with one hand. Unlike recessed or segmented platforms, there are no gaps between components where powder can accumulate.

• Practical Impact: Cleaning time is reduced by 60%—from 2 hours to just 48 minutes for a full sanitization. For a manufacturer running 3 shifts daily, this saves 144 hours of labor annually.

This design isn’t just about convenience—it also supports GMP compliance by minimizing cross-contamination risks, a critical requirement for any pharmaceutical blister machine.

2. Modular Workstations + Integrated Aluminum Alloy Rails: Simplify Maintenance & Reduce Wear

Traditional machine models often have fixed station that require disassembling half the machine for maintenance. The DPP-Max series adopts a fully modular design paired with high-grade aluminum alloy rails, addressing both usability and durability:

• Modular Advantage: Each core workstation (forming, heat sealing, creasing, punching) is a independent module that can be pulled out along the aluminum rails. This means replacing a heat sealing component takes 15 minutes instead of 2 hours, as operators don’t need to disconnect adjacent parts.

• Aluminum Alloy Benefits: The rails are made of 6061-T6 aluminum alloy, which offers 200% higher corrosion resistance than steel and a friction coefficient of just 0.15. This reduces wear from repeated module movement, extending the pharmacy blister packing machine’s lifespan by 30%.

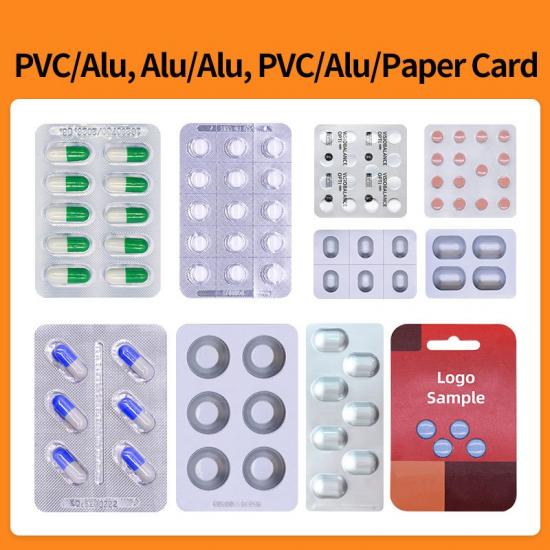

This modularity also makes the DPP-Max series a flexible high speed blister packaging machine—switching between Alu-PVC and Alu-Alu materials only requires swapping the forming module, no major reconfiguration needed.

3. Drawer-Type Mold Installation: 15-Minute Changes to End Production Downtime

Mold replacement is one of the biggest pain points for any automatic blister packaging machine user. Traditional models require aligning bolts, calibrating positions, and testing for hours—often taking 1–2 hours per change. The DPP-Max series’ drawer-type mold design revolutionizes this process:

• Mechanical Innovation: The mold uses a precision draw-out slot system with built-in positioning pins (tolerance ±0.1mm). Operators simply pull out the old mold, slide in the new one, and lock it—no tools required.

• Efficiency Breakthrough: Mold change time is reduced to 15 minutes, a 750% improvement over traditional models. For a manufacturer switching between 3 product molds weekly, this saves 35 hours of downtime annually.

• Error Reduction: The built-in positioning pins eliminate human error in alignment, ensuring consistent blister quality (e.g., seal tightness, punch accuracy) from the first run.

This feature is especially valuable for small-batch pharmaceutical production, where frequent mold changes are common—turning a frustrating delay into a quick, seamless process.

4. Spindle Positioning for 4 Workstations + External Handwheel: Precision Adjustment Without Guesswork

Aligning forming, heat sealing, creasing, and punching working station is a nightmare for most flat plate blister machine operators—traditional models rely on trial-and-error, with no clear feedback on position. The DPP-Max series solves this with spindle positioning and an external handwheel:

• Precision Engineering: All 4 workstations use a hardened steel spindle (surface hardness HRC 55) for positioning, ensuring accuracy within ±0.1mm. This is critical for heat sealing—even a 0.2mm misalignment can cause seal defects (e.g., air leakage, uneven edges).

• User-Friendly Control: An external handwheel with digital position display lets operators adjust each workstation independently. Unlike hidden controls, the handwheel is intuitive to use, and the digital readout (resolution 0.01mm) eliminates guesswork.

This design turns a 105-minute adjustment process into a 5-minute task, reducing setup time and improving product consistency.

5. Siemens Servo System + Global Brand Components: Reliability & Worldwide Support

A blister packing machine is only as good as its core components. The DPP-Max series uses industry-leading technology to ensure long-term reliability and global after-sales support:

• Siemens Servo Motor & PLC: The machine’s traction system is driven by a Siemens servo motor (model 1FL6064) with a positioning accuracy of <0.1‰—ensuring blister film moves smoothly without slippage. The Siemens PLC (S7-1200) and touchscreen allow one-click parameter adjustment (e.g., temperature, speed), eliminating manual calibration errors.

• Global Brand Partners: Key components include Omron sensors (for defect detection), Schneider electrical components (for safety compliance), and IDEC switches—all brands with a global presence. This means operators in the US, EU, or Southeast Asia can easily source replacement parts and access local technical support.

• Durability Data: The mean time between failures (MTBF) of the DPP-Max series is 35,000 hours—2x longer than average models. This reduces unplanned downtime by 40% for manufacturers.

Why the DPP-Max Series Stands Out

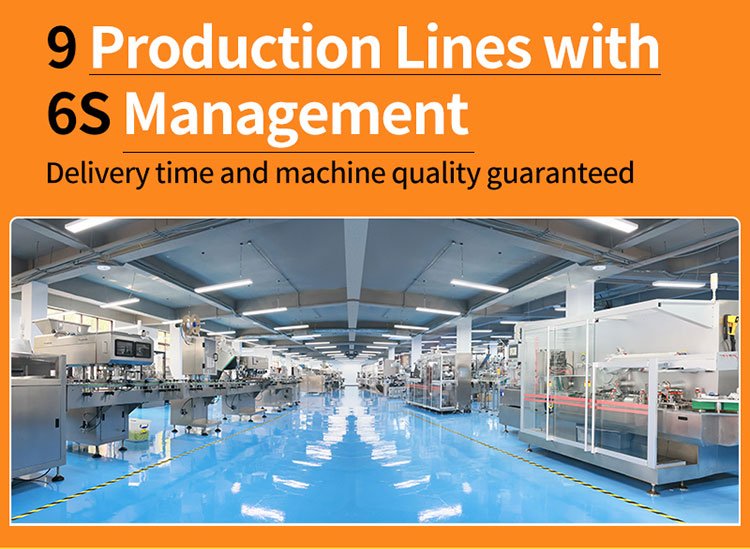

The DPP-Max series isn’t just a high speed blister packaging machine—it’s a testament to Rich Packing’s expertise in solving real-world manufacturing challenges:

• Expertise: 32 years of pharmaceutical machinery R&D, with feedback from 4,200+ global customers shaping the DPP-Max design.

• Authoritativeness: The series holds CE, cGMP, and ISO certifications, meeting strict pharmaceutical standards worldwide.

• Trustworthiness: 3-year component warranty, 1-year free wearing parts, and global on-site installation/training—ensuring customers get long-term value.

At industry expos like CPhI Shanghai, the DPP-Max series has drawn praise from pharmaceutical manufacturers: “We used to spend 2 hours daily cleaning our old blister packing machine,” said a representative from a Southeast Asian nutraceutical company. “With the DPP-Max, cleaning takes 45 minutes, and mold changes are done in 15—our production efficiency is up 25%.”

Conclusion: End Maintenance Frustration with the Right pharmaceutical Blister Machine

For pharmaceutical and nutraceutical manufacturers tired of maintenance delays, inconsistent adjustments, and costly downtime, Rich Packing’s DPP-Max series is the solution. Its 5 game-changing features—balcony-style platform, modular workstations, drawer-type mold, spindle positioning, and global-grade components—turn a frustrating blister packing machine experience into a seamless one.

Whether you need a blister tablet packing machine, packing capsule blister machine, or a high speed blister packaging machine for large-scale production, the DPP-Max series delivers speed, precision, and ease of use. To learn more about customizing the DPP-Max series for your production needs, contact Rich Packing.

In terms of meeting large-scale production needs, the DPP rapid blister packaging machine takes the lead with its speed and efficiency. Its maximum output can reach 11,200 blister sheets per hour, pushing tablet and capsule packaging to unexplored heights. Irrespective of how niche or unique your requirements are, they can be fulfilled through precise machine operation, ensuring each pharmaceutical product is packaged with superior quality.

But that's not all, the DPP-270max capsule packing machine goes the extra mile by incorporating a dual-cylinder heat sealing structure for precise and in-depth control of sealing pressure. Owing to this creative design, the DPP-270max affords consistent heat sealing regardless of pressure variation. Consequently, the completed blister retains a smooth, wrinkle-free appearance, providing users with superior unboxing experience, and reinforcing product quality.

Our meticulous attention to detail reverberates through more than 30-years of manufacturing and overseas commissioning experience. As one of China's top ten original pharmaceutical blister packaging machine factories, we have catered to over 4,210 customers. We adhere to comprehensive, stringent process standards and a persistence in technology optimization, earning credibility and appreciation from customers worldwide.

In conclusion, the DPP-270max fully automatic tablet packaging machine presents a new blueprint for the future of pharmaceutical packaging. Whether it's its peerless speed, remarkable function, or innovative dual-cylinder heat-sealing design, all these factors conclusively affirm that it is simultaneously progressive and practical. Adopting the DPP-270max marks the advent of industry leadership, enhancement in product quality and user experience, and further attainment of a balance between production efficiency and cost. DPP-270max is not just a machine, but a synonym for solutions that will not only keep you ahead of the competition but also spearhead a new era in pharmaceutical packaging."

IPv6 network supported

IPv6 network supported