Blister Packing Cartoning Machine Line

| Name | Rich Packing DPH270max ZH320W Blister Cartoning Line |

| Capacity | 320 cards/h |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Blister Packaging and Cartoning Production Line Introduction

This is a highly automated and integrated continuous production system widely used in pharmaceuticals, food, medical devices, electronic components, and other fields. Its main function is to package products in blister packs, automatically load them into outer cartons, and complete a series of subsequent operations such as sealing, labeling, and coding. The core advantage of this production line lies in its high degree of automation and integration, which can significantly improve production efficiency, reduce labor costs, and ensure consistent product quality.

In the pharmaceutical industry, blister cartoning lines are essential equipment for achieving automated pill packaging. According to statistics, blister packaging accounts for approximately 30% of the global pharmaceutical packaging market, with a year-on-year growth trend. This packaging method not only effectively protects drugs but also meets strict regulatory requirements, such as drug serialization and traceability. In the food industry, blister cartoning production lines also play a crucial role, especially in packaging products like candies and health supplements, where their application rate exceeds 40%. Additionally, blister cartoning production lines are increasingly used in the medical device and electronic components industries, providing efficient and reliable packaging solutions.

Components of the Blister Cartoning Production Line

The intelligent blister cartoning system consists of multiple core functional modules, each responsible for specific tasks, working together to achieve automation and high efficiency throughout the entire production process.

Blister Packaging Machine

The blister packing machine is the starting point of the production line, responsible for sealing products into blister cavities.

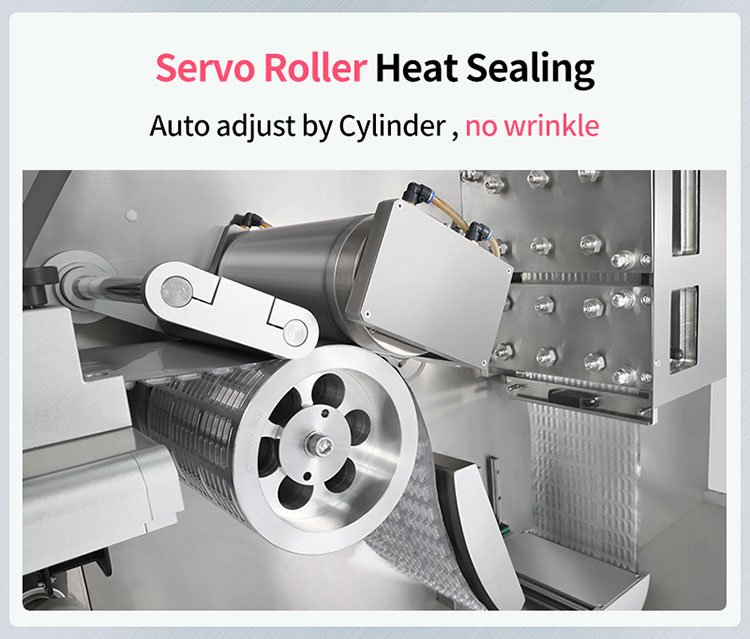

Its working principle involves heating and softening plastic film or cold-forming aluminum foil to form blister cavities on high-precision molds. The products are then automatically filled into the blister cavities and sealed through a heat-sealing process. This process is highly automated, ensuring the forming accuracy and sealing quality of each blister. According to statistics, modern automatic blister packaging machines achieve forming accuracy of over 99.5% and sealing pass rates exceeding 99%.

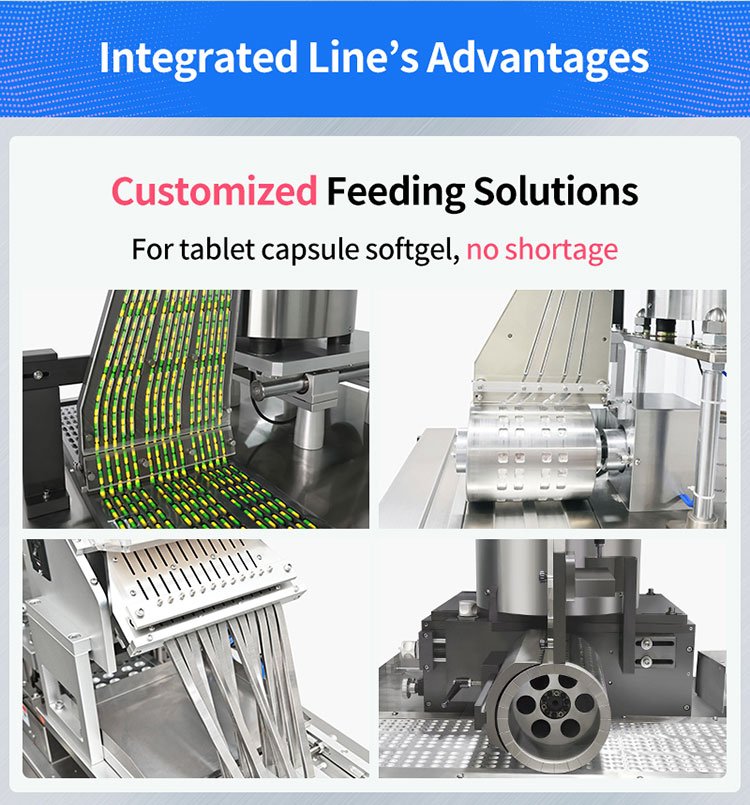

In the pharmaceutical blister machine, the filling and sealing process is a critical step for ensuring product quality. Products (such as tablets, capsules, etc.) are accurately filled into blister cavities via automatic filling devices. These devices typically use vibratory bowls or rail conveyors to ensure precision and consistency during filling. After filling, another roll of aluminum foil or other heat-sealable material covers the blister and is heat-sealed to the plastic base film under heat and pressure, sealing the product inside the blister. The sealing pass rate for this process exceeds 99%, effectively preventing contamination and damage during packaging.

Cutting and output are the final steps of the roller blister packing machine. The main function is to cut the formed and sealed blister sheets or strips into individual packaging units and stably transfer them to the next process. Cutting devices typically use high-precision blades to ensure cutting accuracy and quality.

Inspection and Rejection System

The inspection and rejection system is a critical component for ensuring product quality. It uses vision inspection systems and sensors to monitor products in real-time during production. Inspection items include empty blisters, missing products, broken blisters, poor sealing, as well as missing leaflets, missing blisters, unopened cartons, and improperly sealed cartons during cartoning. If defective products are detected, the system automatically rejects them. In some high-end production lines, the inspection accuracy of the inspection and rejection system can reach 0.01 mm, with a rejection accuracy rate exceeding 99.99%, effectively guaranteeing the quality of the final product.

Conveying System in blister packing cartoning line

The conveying system is a key part connecting various modules, responsible for transferring blister sheets from the capsule blister packaging machine to the cartoner entrance. Its main function is to ensure the correct orientation, smooth movement, and damage-free transfer of blisters during transportation. The conveying system typically includes inline rejection, linear conveyors, directional turners, and buffer storage devices.

The conveying system consists of several key components, each playing an important role in ensuring transfer stability:

Linear Conveyor: This is the core component of the conveying system, responsible for transferring blister sheets from one end to the other. Modern linear conveyors often feature modular designs for easy installation and maintenance, with adjustable speeds based on production needs.

Directional Turner: Used to adjust the transfer direction of blister sheets, ensuring smooth entry into the cartoner. Directional turners are typically driven by high-precision servo motors, enabling fast and accurate directional adjustments.

Buffer storage device: During the production process, the buffer storage device can temporarily store a certain number of blister sheets to adjust the production rhythm. It can effectively alleviate short shutdowns caused by equipment failure or production fluctuations and ensure the continuous operation of the production line.

Automatic Cartoning machine

The automatic cartoner is the core equipment of the production line, responsible for loading blister sheets into cartons and completing operations such as carton sealing and labeling. Its main functions include automatically picking up and opening cartons, inserting leaflets, precisely grabbing blister sheets and loading them into cartons, sealing carton lids, and applying labels and codes. Our automatic cartoners use full servo motor systems and motion control systems, achieving cartoning speeds of 100–300 cartons per minute with a cartoning pass rate exceeding 99.98%. Additionally, some high-end cartoners integrate weight inspection and rejection units, enabling real-time detection and rejection of defective products, further improving product quality.

Control System

The control system is the brain of the entire blister cartoner production line, responsible for coordinating and controlling the operating parameters of all equipment, such as speed, temperature, vacuum level, and position. It uses a human-machine interface (HMI) to achieve parameter setting, operational status monitoring, production data recording, fault diagnosis, and recipe management. Modern control systems typically comply with Industry 4.0 standards and can integrate with SCADA/MES systems for data acquisition and monitoring. According to statistics, blister cartoning production lines equipped with advanced control systems can achieve an overall equipment effectiveness (OEE) of over 85%, significantly higher than traditional production lines.

Advantages of Blister Cartoning Production Lines

Blister cartoning lines demonstrate significant advantages in production efficiency and cost-effectiveness, making them indispensable equipment in modern manufacturing.

Reduced Packaging Material Waste

Precise control systems and excellent mechanical performance ensure accurate blister forming, stable material tension, and precise cartoning actions. According to statistics, production lines with advanced control systems can reduce packaging material waste to below 2%, significantly improving material utilization and saving substantial costs for enterprises compared to traditional production lines.

Lower Product Contamination Risk

Tablet capsule blister carton packing production lines are typically designed to be enclosed or minimize human-machine contact points, with controlled processes that comply with cGMP, FDA, UL, HACCP, and other requirements. This design effectively reduces the risk of product contamination during packaging, which is especially critical in the pharmaceutical and food industries. For example, in drug packaging, measures such as precise counting, in-carton inspection, leaflet insertion, serialization, and traceability ensure drug safety and compliance.

Excellent Production Flexibility

By replacing molds and adjusting parameters, a production line can adapt to products of different specifications and shapes and cartons of different sizes. For example, high-end production lines can partially adjust parameters online without stopping to change molds, greatly improving production flexibility and efficiency. This flexible production method can meet the diversified production needs of enterprises, quickly switch product specifications, and adapt to market changes.

Robust Data Tracking and Management

Modern control systems of tablet blister cartoning machine line provide detailed OEE (overall equipment effectiveness) data, production counts, downtime analysis, batch record reports, etc. These data not only provide strong support for blister cartoning production management, but also provide a strong data foundation for efficiency improvement and quality traceability. For example, by data analysis, pharmaceutical enterprises can optimize production plans, improve equipment utilization, and reduce production costs. In addition, data integration also supports remote monitoring and diagnosis. Technicians can view the operating status of the production line in real time through the network and provide timely technical support

IPv6 network supported

IPv6 network supported