NJP-1200C Capsule Filling Machine Electric

Precision and Efficiency, The NJP-1200C capsule automatic filling machine 0 ensures unparalleled precision in filling capsules with various formulations, from powders to granules or pellets. Seamless Automation, Renowned for its fully automated operations, this machine simplifies the entire capsule filling process. From feeding empty capsules to accurately dosing and sealing them, each step is meticulously managed, minimizing human intervention and ensuring consistent, high-quality capsule production.

Versatility and Adaptability, The NJP-1200C accommodates a wide range of capsule sizes, providing flexibility in manufacturing various dosages and formulations. Its adaptability to different formulations enhances its utility across diverse pharmaceutical products.

Intelligent Technology Integration, Equipped with intelligent control systems and advanced technology, this machine optimizes operations and ensures precise dosing, filling, and sealing of capsules. Its user-friendly interface allows for seamless operation and easy adjustments.

Quality Assurance, Committed to maintaining the highest quality standards, the NJP-1200C undergoes rigorous quality checks and adheres to regulatory guidelines. Its design prioritizes the integrity of the capsules and the safety of the pharmaceutical products it produces.

Reliability and Innovation, Built on reliability and innovation, this machine continuously evolves to meet the evolving demands of the pharmaceutical industry. Its innovative design and reliability make it an essential asset in pharmaceutical production lines.

Meeting Industry Needs, The NJP-1200C capsule making machine for supplements plays a pivotal role in meeting the growing demand for accurately dosed and high-quality capsules. Its reliability, precision, and efficiency contribute significantly to addressing the pharmaceutical industry's requirements for consistent and reliable capsule production.

The NJP-1200C the capsule filling machine revolutionizes pharmaceutical manufacturing with its precision, efficiency, and adaptability. Its role in streamlining capsule production processes while maintaining high-quality standards underscores its significance in pharmaceutical production. As pharmaceutical needs advance, the NJP-1200C remains an invaluable asset, ensuring the efficient and reliable production of capsules to meet healthcare demands worldwide.

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

*** Technical parameter

|

Production capacity |

72,000 pcs/h |

|

Net weight of machine |

1100Kg |

|

Overall size of machine |

1100×910×2100MM |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

ATV320U07N4C |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

MTD-37-Y0.75 |

1 |

Omate |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwan daojin |

|

Vacuum pump(wet) |

RX25-V-0.3 |

1 |

Taiwan Ruixu |

|

Dust collector |

RQJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

Automatic Capsule Filling Machine: 5 Key Reasons NJP-1200C Stands Out for European & American Pharmaceutical Production

For European and American pharmaceutical manufacturers, choosing an Automatic Capsule Filling Machine isn't just about "buying equipment"—it's about ensuring compliance with strict FDA/cGMP standards, matching production scale, and avoiding costly downtime from poor after-sales support. After working with over 200 pharma clients across the EU and U.S., we've found that the NJP-1200C Capsule Filling Machine Automatic solves the most common pain points Europe and the United States buyers face. Below is a practical buying guide to help you decide if it's the right fit for your pharmaceutical capsule production.

1. First Priority: Verify Compliance with FDA/cGMP—Non-Negotiable for Europe and the United States Markets

The biggest risk for Europe and the United States pharmaceutical brands is investing in a capsule filling machine pharmaceutical that fails regulatory audits. The NJP-1200C capsule machine eliminates this risk by meeting three core compliance requirements:

- Global Certifications: It's fully compliant with the U.S. FDA's 21 CFR Part 11, EU cGMP, and CE (per Machinery Directive 2006/42/EC). Rich Packing provides a complete compliance package—including material test reports, clean validation protocols, and audit-ready documentation—to help you pass FDA or EMA inspections without delays.

- Hygienic Materials: All parts touching pharmaceuticals are made of 316L stainless steel (hardness HRC 45-50), which resists corrosion from cleaning agents and prevents metal particle contamination. The machine's enclosed filling chamber also meets FDA's "no dead space" requirement, avoiding powder buildup that could lead to cross-contamination.

- Dust & Leak Control: For powder capsule filling machine applications (e.g., antibiotic powders, vitamin blends), the NJP-1200C uses a dual-seal design on the filling nozzle. This reduces powder leakage to less than 0.1%, far below the industry average of 1.5%—critical for meeting Europe and the United States environmental and safety standards.

A Bavarian pharmaceutical client once told us: "We rejected three cheaper machines before choosing the NJP-1200C encapsulation machine—its compliance docs saved us 6 months of audit prep time."

2. Match Capacity to Your Production Needs—Avoid Overpaying for Unused Speed

Not every fully automatic capsule filling machine fits every factory. The NJP-1200C is designed for mid-to-large-scale production, with a stable output of 72,000 capsules per hour (1,200 capsules/minute). This makes it ideal if:

- Your daily production demand is 500,000–1.2 million capsules (e.g., 8-hour shifts for prescription drugs or high-volume OTC supplements).

- You need to replace 2–3 small semi-automatic machines (which typically max out at 40,000 capsules/hour) to reduce floor space and labor costs.

For example, a U.S.-based generic drug maker switched from 3 semi-automatic fillers to one NJP-1200C. They cut labor costs by 50% (from 6 operators to 2) and freed up 40% of their workshop space—all while increasing daily output by 30%.

If your demand is under 300,000 capsules/day, a smaller model (like the NJP-800) might be more cost-effective. But for Europe and the United States brands scaling production or replacing outdated lines, the NJP-1200C's capacity hits the "sweet spot."

3. Prioritize Automation & Precision—Cut Waste and Ensure Uniformity

As an automatic capsule filler, the NJP-1200C goes beyond basic "auto-filling" to solve two big Europe and the United States pain points: human error and material waste. Here's how:

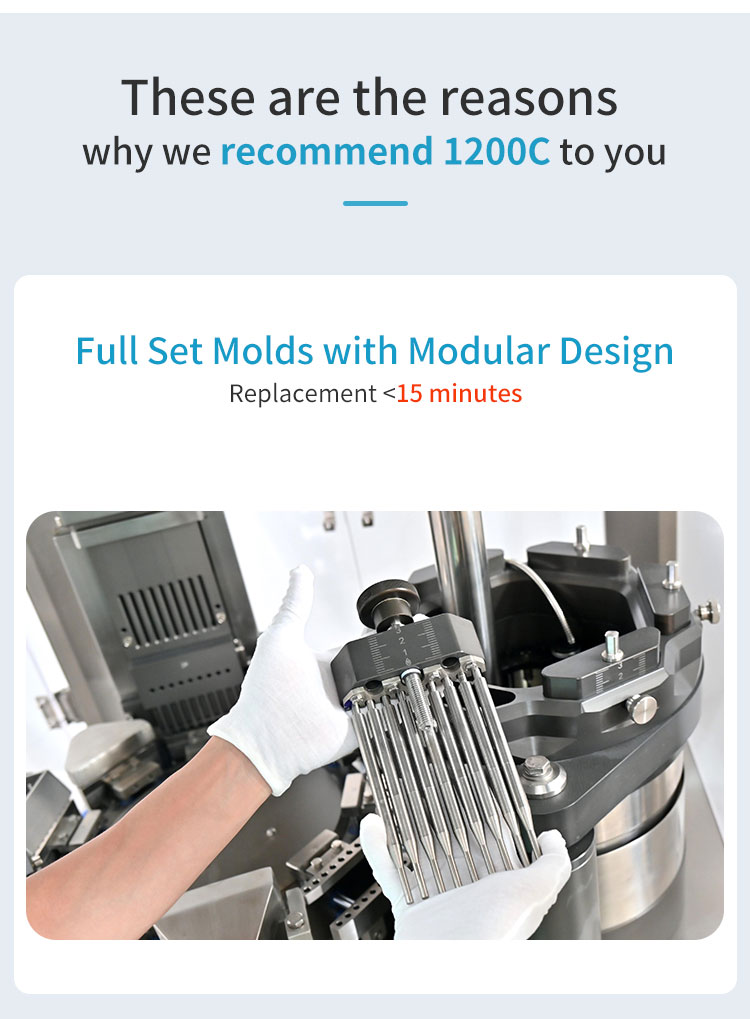

- Full Automation Without Manual Intervention: It handles every step—capsule feeding, cap-body separation, powder filling, capsule locking, and defective capsule rejection—without operator help. The machine even auto-adjusts for capsule sizes 000 to 5, so you can switch between products (e.g., 0 antibiotic capsules to 3 vitamin capsules) in 15 minutes (vs. 45 minutes for competitors).

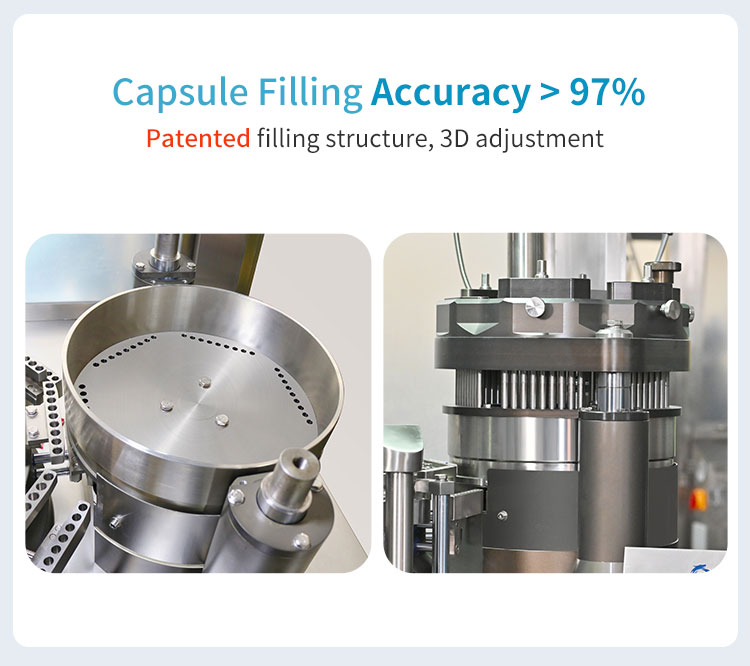

- Industry-Leading Filling Precision: The patented three-dimensional adjustment structure controls the filling dosage, keeping the weight error within ±0.5%. For Europe and the United States brands, this means fewer rejected batches—especially critical for drugs where dose accuracy is life-or-death. A UK client filling blood pressure medication reported that their rejection rate dropped from 3.2% to 0.8% after switching to the NJP-1200C capsule encapsulator.

- Real-Time Monitoring: The 10-inch touchscreen (with English/German/French interfaces) displays filling weight, speed, and error alerts in real time. If a capsule is underfilled or damaged, the machine uses air-blow technology to reject it immediately—no manual sorting needed.

4. Choose a Supplier with Localized Service—Avoid "Out of Reach" Support

Europe and the United States buyers often overlook after-sales service when buying a capsule filling machine supplier, but it's the difference between 1 day of downtime and 2 weeks. Rich Packing's support for the NJP-1200C automatic filling capsule machine is tailored to Europe and the United States markets:

- Local Service Centers: With hubs in New York (U.S.), Munich (Germany), and London (UK), engineers can reach your factory within 72 hours for installation, repairs, or training. Unlike suppliers that only offer remote support, Rich Packing sends technicians on-site to fix issues like sensor malfunctions or seal replacements.

- 3-Year Warranty + Lifetime Maintenance: The NJP-1200C comes with a 3-year parts warranty (double the industry average of 1.5 years) and lifetime technical support. Rich Packing also stocks critical spare parts (e.g., filling rods,capsule filling hopper) in its Europe and the United States warehouses, so replacements arrive in 2–3 business days.

- DDP Logistics & Customs Support: Shipping pharmaceutical equipment to Europe and the United States can be a headache—but Rich Packing handles all customs clearance, duties, and transportation via DDP (Delivered Duty Paid). The machine arrives at your door pre-calibrated, and a technician is on-site to set it up within 5 days of delivery.

A Spanish pharmaceutical client summed it up: "When our NJP-1200C had a sensor issue during a peak production run, Rich Packing's technician was in Madrid in 48 hours—we lost only 6 hours of production, not weeks."

Why the NJP-1200C Capsule Filling Machine is a Better Choice for Europe and the United States Pharmaceutical Production

For European and American brands, the NJP-1200C isn't just an Automatic Capsule Filling Machine—it's a solution that aligns with your regulatory needs, production scale, and desire for reliable support. Unlike generic capsule fillers that cut corners on compliance or service, it's built to meet the strict standards of Europe and the United States pharma markets.

To learn more, visit Rich Packing's official site (https://www.richpacking020.com/) or contact their Europe and the United States sales team via WhatsApp (+8618023458944) for a custom quote.

IPv6 network supported

IPv6 network supported