NJP 1500D Automatic Capsule Filler Capsule Filling Machine of Rich Packing

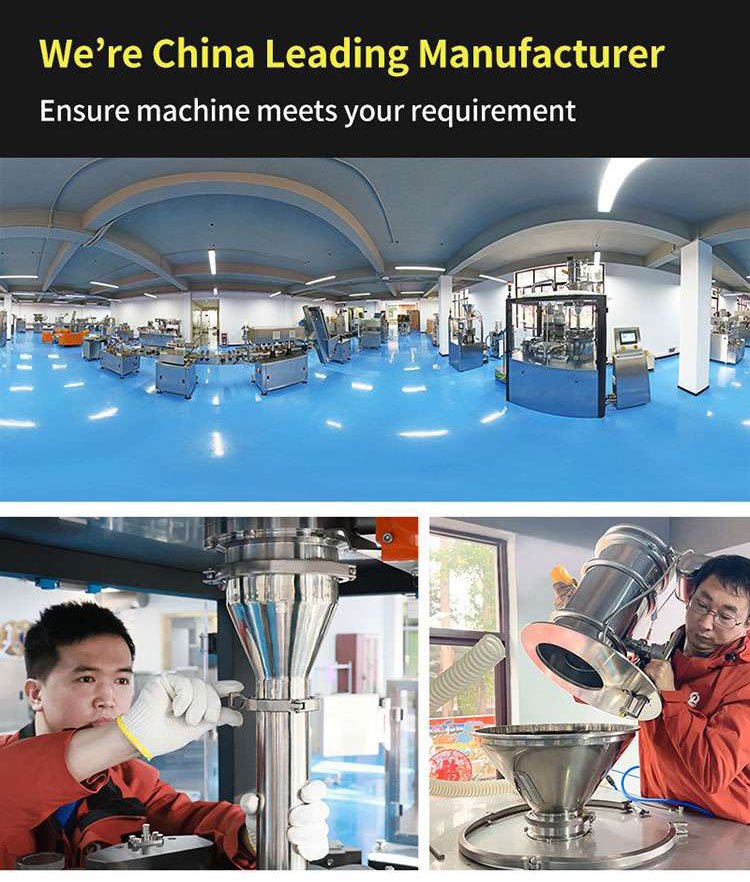

This type of 1500D capsule filling machine can be widely used in many pharmaceutical enterprises, such as the Chinese, Western medicine making enterprise, health care product enterprise,and etc. This kind of capsule making machine can rapidly improve the production efficiency, and the whole process of the capsule filling working can be completed automatically. It in accord with the related rules of GMP standards, totally meets the needs of the clients, it has zero harmful to human, all parts of the 1500D equipment that people can touch are totally safe.

This 1500D Capsule filling machine is straight forward to use, convenient to cleaning, quick to replace the mold of the machine. It can working continuously for a very long time,in 24 hours and 7 days, don’t need to shut off it, just let it running, it is an ideal for mass capsule making production.It can run as rapidly as it can, at a very high speed of 90,000 pieces in a hour, and it consumes less energy, creates a high output at the same time, very economic and beneficial.

*** Why choose us? Capsule filling machine has high degree of the filling precision rate, the making rate of empty capsule is up to 99.9%, and the full capsule is up to 99.8%, and it is clean working without any dirt, making very environmental. Zero noise can be heard during the working process of capsule filling, zero damage to the finished capsules, zero stick of the pharmacy material, zero stick with the filling rods mold, moisture can be absorbed by this capsule filler machine. In addition, the Teflon coating processing service can be provided by us according to the needs of the customers and the material natures.

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

*** Technical parameter

|

Production capacity |

90000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size of machine |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

|

No.of segment bores |

9 |

|

Vacuum |

40m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Noise |

<75DB(A) |

|

Making rate |

Empty capsule99.9% Full capsule99.8% |

|

Applicable capsule |

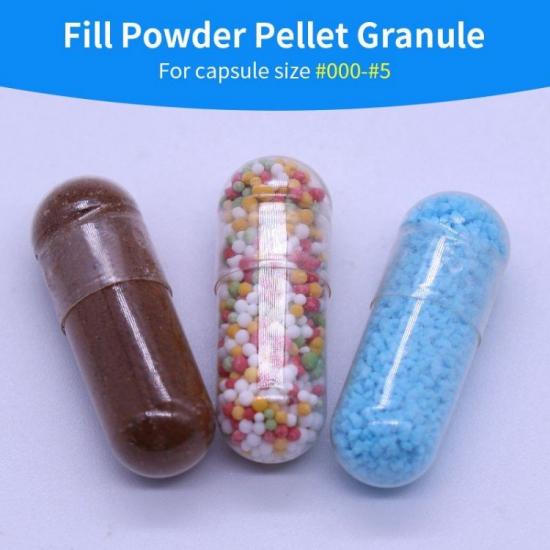

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Power、granule、pellet、tablet |

|

Packing size |

1490×1260×2150mm |

*** Configuration List

|

Item |

Specification |

Qty. |

Manufacturer |

|

Touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Germany Siemens |

|

PLC |

6ES7/288-1ST20-0AA0 |

1 |

Germany Siemens |

|

AC Contactor |

3TB42 |

4 |

Germany Siemens |

|

Frequency converter |

VFD015 B21A |

1 |

Taiwan Delta |

|

Thermal relay |

3UA59 |

3 |

Germany Siemens |

|

Button |

ZB2-BA3C |

3 |

Schneider |

|

Main Motor |

CH-30-1100W |

1 |

Dongli |

|

Cam |

RU-83DS-10 RU-83DS-6 |

2 |

Taiwandaojin |

|

Vacuum pump(wet) |

SK-0.5A |

1 |

Shanghai |

|

Dust collector |

XLJ Series |

1 |

Self-made |

|

Linear bearing |

LM10UU |

40 |

Korea SAMICK |

|

Linear bearing |

LM12UU |

48 |

Korea SAMICK |

|

Linear bearing |

LM20UU |

8 |

Korea SAMICK |

|

Linear bearing |

LM40UU |

4 |

Korea SAMICK |

|

Roller bearing |

CF6B |

10 |

Japan IKO |

|

Roller bearing |

CF12B |

5 |

Japan IKO |

|

Roller bearing |

CF18B |

1 |

Japan IKO |

|

Deep groove ball bearing |

6200 |

10 |

JapanNSK |

How Fully Automatic Capsule Filling Machines Precisely Control Capsule Filling Dosage

I. Introduction: Precise Filling - A Core Technical Requirement for Capsule Formulation Production

For capsule formulations, the precision of filling dosage is a core element ensuring drug efficacy and safety. Precise filling dosage guarantees that the drug content in each capsule meets therapeutic requirements, enabling patients to achieve stable and effective treatment outcomes. Conversely, dosage deviations may lead to insufficient efficacy, delayed treatment, or even adverse reactions, posing serious threats to patients' health.

As the core equipment for achieving precise capsule filling, capsule filling machines fully automatic are of paramount importance. Through the coordinated operation of mechanical structures, control systems, and process parameters, automatic capsule machines accurately fill drugs into capsules. How to further enhance their ability to precisely control capsule filling dosage and meet the increasingly stringent production demands of pharmaceutical enterprises has become a topic requiring in-depth research. This article will analyze, from multiple dimensions including technical principles, key influencing factors, innovative technologies, and quality control standards, how fully automatic capsule filling machines achieve the target of controlling dosage variation within ±3%, providing professional and detailed reference for pharmaceutical enterprises in equipment selection and process optimization.

II. Technical Principles and Core Components of Precise Filling in Fully Automatic Capsule Filling Machines

(I) Dosage Control Logic in the Workflow

Based on an intermittent rotary design, pharmaceutical capsule filling machines complete the entire process - including directional arrangement, body-cap separation, drug filling, locking, and rejection - through a 12-station indexing mechanism. At the filling station, the dosage disc and filling plungers form the core metering unit: the precision holes on the dosage disc have apertures matching capsule sizes (e.g., 6.3mm for 0 capsules). After materials are evenly distributed into the holes by a vibrator, the filling plungers perform progressive compaction through 5 stations (total preset position depth ≤ 0.35% of the dosage disc thickness), pressing the powder column into the capsule body. By controlling the matching degree between the volume of the dosage hole (V = πD²h/4) and the bulk density of the material (ρ), precise calculation of the theoretical filling volume (W = kρV, where k is the preset coefficient) is achieved.

(II) Precision Design of Core Components

1. Material and Process of Dosage Discs and Filling Plungers: The NJP capsule filling machines adopt SUS316L stainless steel for manufacturing dosage discs and filling plungers, with a surface roughness ≤ Ra 0.8μm to reduce material adhesion and residue. The thickness tolerance of the dosage disc is controlled within ±0.01mm, and the hole perpendicularity error is < 0.05°, ensuring consistent filling volume across all stations. Rich Packing's NJP series capsule machines increase the diameter of the dosage disc to improve powder flow uniformity, reducing the filling volume variation between the first and last stations to ±2.5%.

2. Synergistic Effect of Vibration and Vacuum Systems: The automatic filling powder capsule machine is equipped with a second vibration motor (with adjustable frequency of 50-100Hz) in the hopper and dosage disc, which works with an electromagnetic vibration feeder to stabilize the void fraction of material particles between 30% and 40%, avoiding filling deviations caused by fluctuations in bulk density. The vacuum system uses negative pressure suction of 0.04-0.08MPa, ensuring a capsule body-cap separation rate > 99.9% and laying the foundation for precise filling.

III. Key Factors Affecting Filling Dosage Precision of Fully Automatic Capsule Machines and Control Strategies

(I) Optimal Design of Mechanical Structure Parameters

1. Dynamic Adjustment of Filling Plunger Preset Coefficient: During capsule filling, the preset coefficient (k) of the filling plunger in capsule filling machine pharmaceutical plays a key role in dosage precision. It can be precisely adjusted according to the properties of different materials using the formula k = 1 + Σ△hi/5.5h (where △hi is the pressing depth of the filling plunger at each station). For example, powders with poor flowability may lead to insufficient filling volume under the same filling conditions. In such cases, the k value can be appropriately increased manually or via an automatic control system. Take hygroscopic cephalosporin drug powders as an example: they tend to adhere to the filling plungers and dosage discs during filling, reducing the actual filling volume. By adjusting the k value from 1.0 to 1.03, the insufficient filling volume caused by material adhesion is effectively compensated. Practical tests show that the filling volume variation is significantly reduced from ±4% to ±2.8%, greatly improving filling dosage precision.

2. Matching Technology Between Dosage Holes and Capsule Specifications: Establishing a comprehensive database of capsule models and dosage hole parameters is essential for precise filling of automatic capsule filler. For instance, 1 capsules correspond to a 5.65mm aperture, and the theoretical filling volume is 25.06mg calculated based on material bulk density and relevant formulas. To meet the needs of small-batch, multi-variety production, the equipment adopts a modular dosage module design. When changing capsule models, operators only need to quickly replace the corresponding dosage module to achieve rapid switching between 00-5 capsules, with the entire switching process completed within 30 minutes. Moreover, due to the high-precision modular design, the filling precision does not require recalibration after switching, ensuring production continuity and stability while effectively improving production efficiency and product quality.

(II) Adaptive Control of Material Properties

1. Real-Time Monitoring of Bulk Density and Filling Coefficient: The bulk density and filling coefficient of materials are important factors affecting filling dosage precision. The capsule machine automatic uses an online density sensor (with a precision of ±0.5%) to accurately monitor material bulk density (ρ) in real time. Meanwhile, a correction model for the filling coefficient (φ) (φ = measured W / 0.785kD²h) is established based on historical production data. During production, if the coefficient of variation (CV) of the mixed material exceeds 5% (indicating fluctuations in material uniformity that may cause unstable filling dosage), the system automatically triggers a vibration frequency adjustment mechanism. By changing the vibration frequency, materials are distributed more evenly in the dosage disc, controlling the fluctuation of the φ value within ±1.5% and ensuring consistent filling of materials across different batches, thus effectively improving product quality stability.

2. Special Treatment for Materials with Poor Flowability: For viscous drug powders (e.g., traditional Chinese medicine extract powders), poor flowability and easy adhesion to equipment components pose significant challenges to filling. To address this, Rich Packing coats the bottom of the filling plungers of its NJP encapsulation machines with an anti-static coating (surface resistance ≤ 10⁶Ω) and a fluorocarbon coating (contact angle > 110°). The anti-static coating reduces material adhesion caused by electrostatic effects, while the fluorocarbon coating, with its high contact angle, prevents materials from adhering to the surface of the filling plungers. Additionally, a first vibration motor (with an adjustable amplitude of 0.1-0.3mm) is built into the filling mechanism; through micro-amplitude vibration, the material adhesion rate is further reduced to < 0.5%. Furthermore, a forced feeding device (with an adjustable rotation speed of 5-15rpm) is adopted, and the rotation speed is adjusted according to material properties to ensure smoother material entry into the dosage holes. This increases filling efficiency by 20% and stabilizes the filling volume variation within the ±3% standard range, meeting production requirements for precision and efficiency.

(III) Precise Regulation of Intelligent Control Systems

1. Closed-Loop Control with PLC and Sensors: The capsule filling machine filler integrates a high-precision weight sensor (precision ±0.1mg) and a displacement sensor (resolution 0.01mm) via a PLC controller, forming an efficient and precise closed-loop control system. During capsule filling, the sensors collect filling volume data in real time and compare it with the preset value. If the deviation exceeds ±2%, the system responds quickly, automatically adjusting the filling plunger pressure (adjustable 0.5-2kN) and the rotation speed of the dosage disc (10-30rpm). The response time of the entire "detection-feedback-adjustment" closed loop is < 0.2 seconds, ensuring that the filling dosage quickly and accurately returns to the preset range, significantly improving filling precision and production stability.

2. Parameter Visualization Management via HMI: The Siemens touchscreen interface of the powder capsule filling machine serves as a key human-machine interaction window, displaying real-time key indicators such as filling volume standard deviation (σ) and CPK process capability index (target ≥ 1.33). Operators can intuitively monitor data fluctuations during production and identify potential issues in a timely manner. Meanwhile, the interface supports historical data traceability with a storage period of ≥ 180 days, facilitating operators to review and analyze production data to identify patterns and problems in the production process. In addition, through hierarchical password permission settings, only authorized personnel can modify key parameters, effectively preventing interference from unauthorized operations on the production process and ensuring the traceability and compliance of the production process, thus providing strong support for product quality.

IV. Conclusion: Precise Filling Technology Empowers High-Quality Development of the Pharmaceutical Industry

The dosage control precision of fully automatic capsule filling machines is an integrated manifestation of multi-disciplinary technologies including mechanical engineering, materials science, and intelligent control. Through the precision design of metering units, adaptive control of material properties, and closed-loop adjustment of intelligent systems, most current pharmaceutical capsule machines have achieved dosage variation control within ±3%, meeting the production requirements of most drugs. Rich Packing's NJP fully automatic capsule filling machines continue to make breakthroughs in precision, flexibility, and energy efficiency, achieving dosage control of ±1% and providing more reliable support for the global pharmaceutical industry.

IPv6 network supported

IPv6 network supported