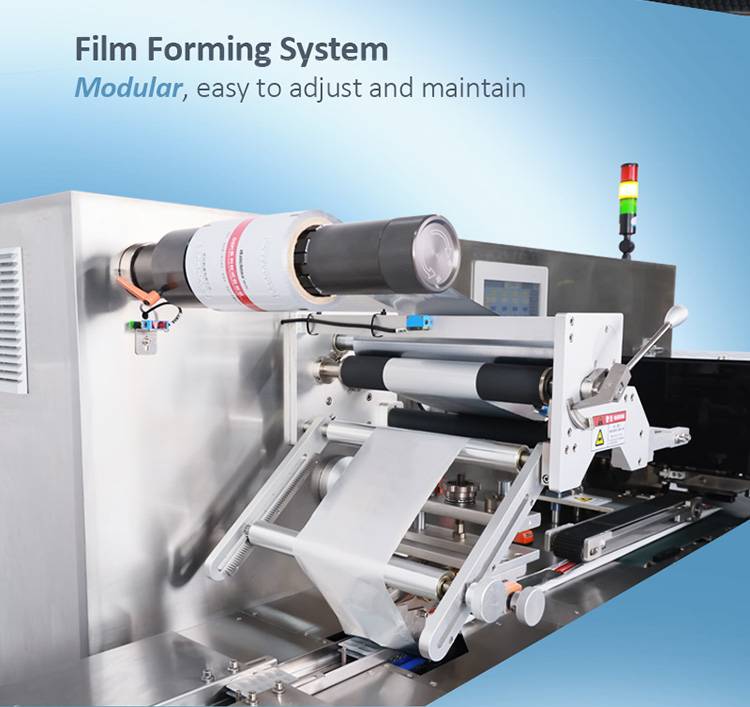

The flow wrap machine is a mechanical device used to wrap products in pre-formed plastic film or composite film and seal them. The flow wrap machine can achieve high-speed continuous operation and automatically complete the feeding of packaging materials, film forming, product discharge, multi-side sealing, front and rear end cutting and output.

RQ-HPP-180 pillow packing machine has many advantages over similar products.

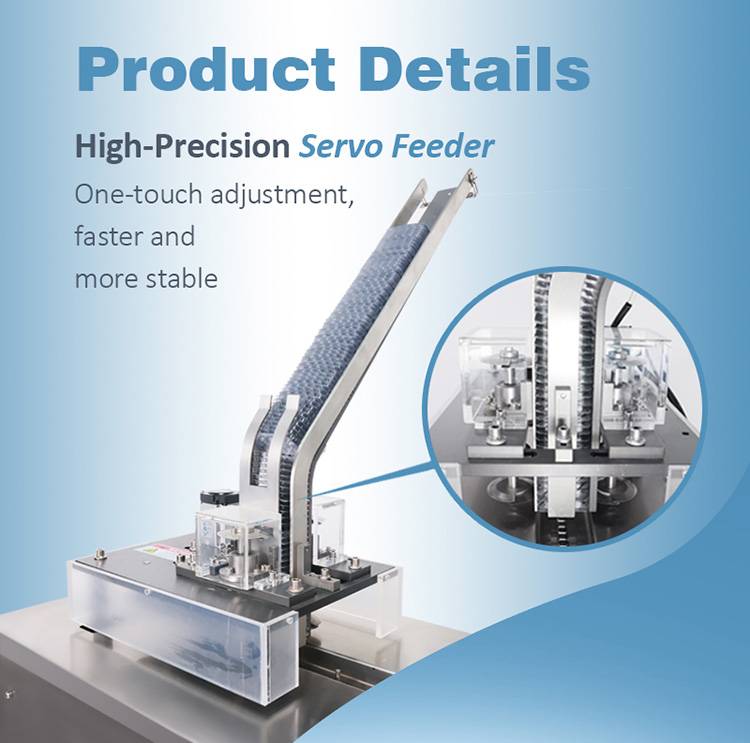

High Automation: The machine uses five servo motors, distributed across the feeding, conveying, film unwinding, middle sealing, and cutting stations.

N+0 Motion Control and PLC Servo Dual-Control System. This flow wrapper features fast speeds and multiple actions, with motion control and servo control seamlessly integrated.

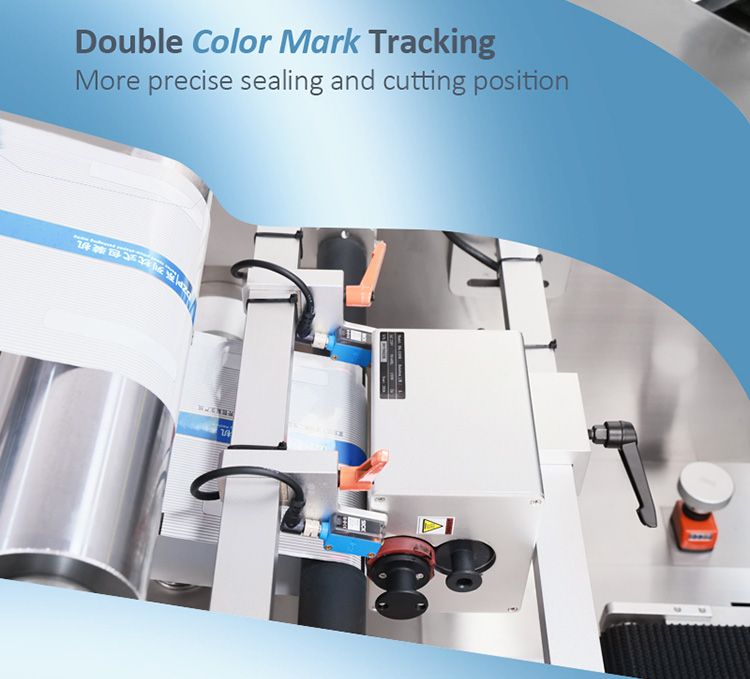

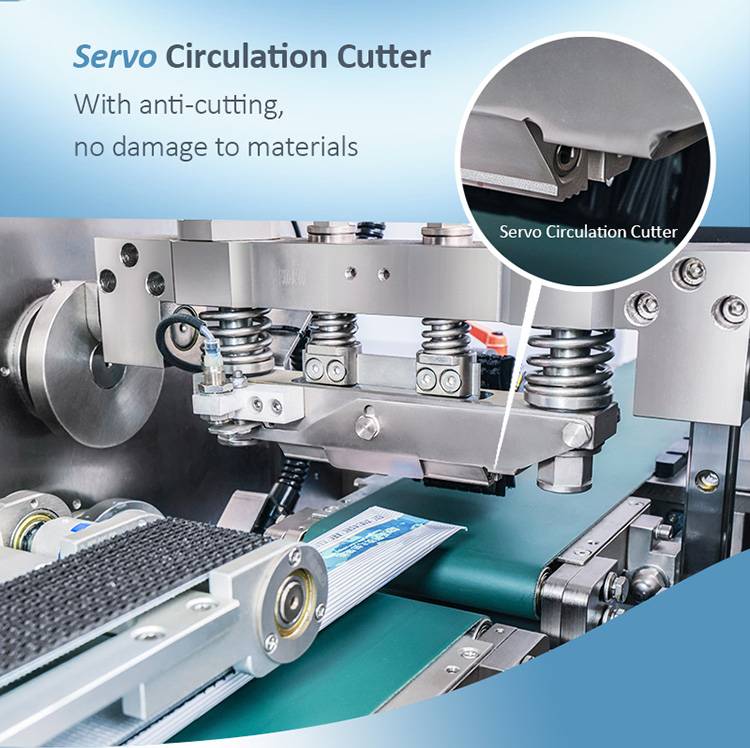

Exclusive Bidirectional Circular Cutter Design: The integrated cutter design creatively combines sealing and cutting into one process. The cutting blade is placed inside the heat-sealing mold, and its bidirectional movement synchronizes with the sealing process. This design extends the heat-sealing duration, ensuring excellent sealing quality, achieving high speeds with a maximum rate of up to 180 bags per minute.

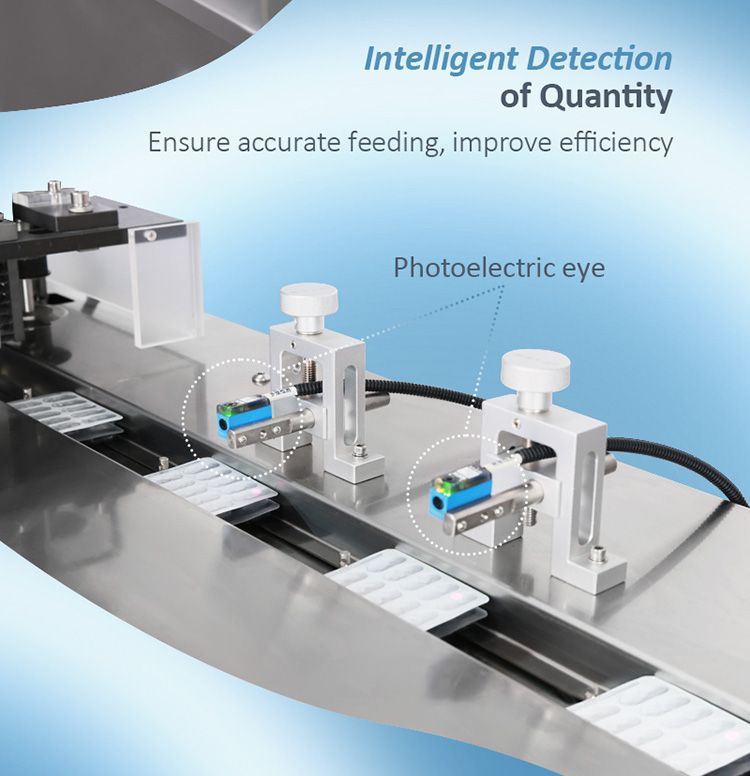

Front and Rear Data Sharing: The system eliminates empty packaging with a 100% success rate. When there is no material, the machine automatically stops film pulling, and the cutter also halts, ensuring no empty bags are produced. This highlights the machine's operational efficiency and economic advantages.

Precise Servo-Controlled Operations: The system utilizes servo mechanisms for feeding, film pulling, film unwinding, and cutting. The bag length is accurately controlled by servo motors, and adjustments to feeding speed, film unwinding, and cutting are automated, providing excellent stability.

The RQ-180 high-speed pillow packaging machine has been significantly improved in terms of stability, continuity, durability, sealing performance, and overall efficiency, ensuring the safety and reliability of pharmaceutical packaging. It can also be used with blister packaging machines and cartoning machines. Machines are seamlessly connected to achieve flexible and efficient production.

| Machine Type | Flow Wrapper |

| Model | RQ-HPP-180 |

| Production | 90-180 bags/min |

IPv6 network supported

IPv6 network supported