High precision Checkweigher

| Product Name | High Precision Checkweigher |

| Precision | ± 0.01g |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

High Precision Checkweigher Overview

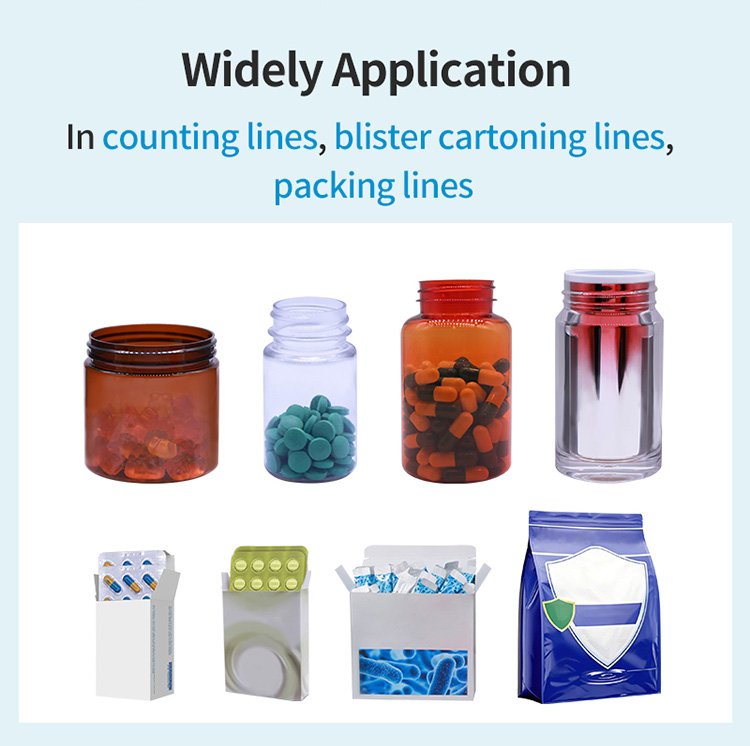

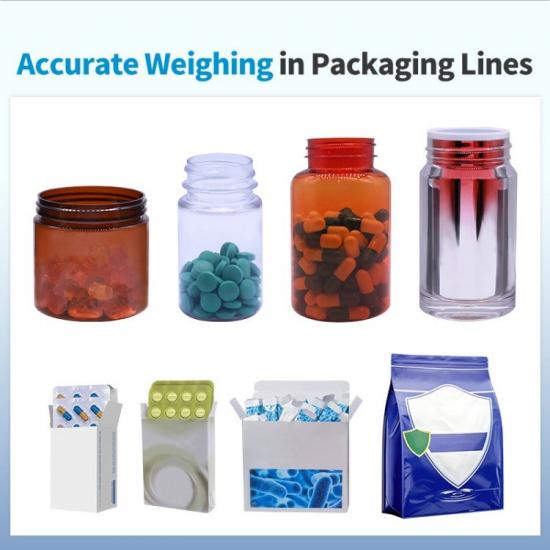

A check weigher is a high-speed dynamic weighing device widely used in industrial production. It utilizes high-precision sensors to measure product weight in real-time and automatically sorts out non-compliant products, ensuring product quality meets standards. Our primary application areas include:

Pharmaceutical and Health Product Industries: Integrated at the end of tablet capsule bottling production lines, it packages products such as tablets, capsules, and gummies, providing higher counting accuracy and ensuring the accurate quantity in each bottle.

Food Industry: Connected to the end of blister cartoning packaging lines, it checks the net weight of boxed and bagged products to ensure compliance with standards and prevent shortfalls.

Chemical Industry: Linked to powder filling lines, it provides real-time feedback on powder filling volume deviations, ensuring consistent weight in each bag or bottle.

Beverage Industry: Linked to liquid filling lines, it provides real-time feedback on liquid filling volume deviations, ensuring the precise volume of each bottle.

How a High Speed Checkweigher Works

A sensor converts the force of gravity acting on a product into an electrical signal, which is then digitally processed for dynamic weighing. The check weigher's workflow is as follows:

1. Dynamic Weighing: As products pass over the load cell, the sensor converts the weight signal into an electrical signal. After amplification and filtering, this signal is converted into a digital signal for high-precision weighing. Its accuracy range reaches ±0.01 g, and its maximum processing speed can reach 300 pcs/min.

2. Automatic Sorting and Rejection: The system rejects overweight, underweight, or missing products in real-time based on preset weight thresholds. It also supports multi-level sorting, such as grading products by weight range.

3. Data Statistics and Analysis: The system records parameters such as pass rate, average weight, and standard deviation, and generates trend reports (e.g., batch pass rate statistics) to help companies monitor production quality in real-time.

4. Packaging Integrity Testing: High-precision weighing can identify missing components (such as drug inserts) or missing items (such as accessories in snack bags), ensuring packaging integrity.

Checkweigher Technical Specifications

Accuracy Range

The accuracy range is one of the core performance indicators of a high accuracy checkweigher, directly impacting the precision of product quality control. According to industry standards, the accuracy range of a checkweigher is typically within ±1 g. Our machine achieves a detection accuracy of up to ±0.01 g.

Pharmaceutical and Health Supplement Industries: Due to the relatively light weight of products and extremely high precision requirements, checkweighers typically achieve an accuracy of ±0.01 g, ensuring each tablet or capsule meets the standard weight.

Health Supplement and Food Industry: For heavier packaged products, such as large food bags, the accuracy range may be relaxed to ±1 g while still meeting basic quality control requirements.

Based on actual application data, our US customer, US-Pharma, utilized an RQ checkweigher on a pharmaceutical packaging production line. Test results showed that within an accuracy range of ±0.01 g, the RQ checkweigher achieved a 99.99% acceptance rate for compliant products and a 99.9% rejection rate for non-compliant products. This demonstrates that our high-precision checkweighers effectively enhance customers' product quality control and address their pain points.

Processing Speed

Processing speed is a key parameter measuring a checkweigher's efficiency, determining the number of products the device can process per unit time. Typically, checkweighers operate at speeds between 100 and 300 items/minute, depending on the device's design and application. For example, in high-speed production lines such as capsule/tablet counting lines and powder filling lines, checkweighers typically achieve processing speeds of up to 300 items/minute to meet large-scale production demands.

Production Line Types Suitable for High Precision Checkweighers

Compatibility with Counting and Filling Lines

The application of dynamic conveyor checkweigher in counting and bottle filling lines is crucial, particularly in the pharmaceutical and health supplement industries.

High-Precision Counting: In packaging small-particle products like tablets and capsules, checkweighers use high-precision dynamic weighing to accurately count products with an accuracy of ±0.01 g, ensuring the precise quantity in each bottle. For example, after implementing a checkweigher, US pharmaceutical company Robinson Pharma increased its tablet counting accuracy from 95% (using traditional methods) to 99.99%, significantly reducing defective products due to miscounting.

Seamless Integration with Packaging Lines: Checkweighers integrate seamlessly at the back-end of pill-counting and packaging lines, enabling fully automated production processes. Their automatic sorting and rejection function instantly removes overweight or underweight products, preventing non-compliant products from reaching the market. In practice, a health supplement company increased its rejection efficiency by 40% using checkweighers, while also reducing manual sampling and labor costs.

Data Statistics Assist Quality Monitoring: The checkweigher records data such as pass rate, average weight, and standard deviation, which can be used to generate trend reports, helping companies monitor production quality in real-time. On pill-counting and bottling lines, this data helps companies promptly identify abnormal fluctuations in the production process, enabling timely adjustments to ensure consistent product quality. For example, our Algerian client, MEDEC, a pharmaceutical manufacturer, analyzed checkweigher-generated trend reports and discovered a decline in product acceptance rates over a specific period. Investigation revealed a malfunction in the filling equipment. Prompt repair restored the acceptance rate to normal.

Packaging Line Adaptation

Checkweighers are widely used and highly effective in packaging lines, particularly in the pharmaceutical and food industries.

Net Weight Measurement and Quality Control: Connected to the end of packaging lines, checkweighers measure the net weight of boxed and bagged products in real-time to ensure compliance with weight standards. Their accuracy range spans from ±0.01 g to ±1 g, depending on the product type and packaging specifications. For example, on a food packaging line, a company using a checkweigher with ±0.05 g accuracy increased its product acceptance rate from 90% to 98%, effectively preventing underweight products and reducing customer complaints.

Automatic Sorting and Efficiency Improvement: The checkweigher's automatic sorting and rejection function instantly rejects overweight, underweight, or missing products, supporting multi-level sorting such as grading by weight range. In real-world applications, a food company utilized this function to increase rejection efficiency for non-compliant products by 50%, while reducing manual intervention and lowering error rates.

Packaging Integrity Inspection: Checkweighers employ high-precision weighing to identify missing components or items, such as absent drug inserts or missing parts in snack bags. On a pharmaceutical packaging line, a company increased the acceptance rate for packaging with missing inserts from 85% to 99%, significantly improving packaging integrity and product quality.

Powder Filling Line Adaptation

Powder filling lines place high demands on checkweighers, particularly regarding accuracy and real-time feedback.

Real-time Feedback on Filling Volume Deviation: Linked to powder filling machines, checkweighers provide real-time feedback on powder filling volume deviations, ensuring consistent weight in every bag or bottle. Their high-precision weighing capability (up to ±0.01 g) effectively detects minute deviations during the powder filling process. For example, on a chemical company's powder filling line, the checkweigher's real-time feedback function reduced fill volume deviation from ±0.5 g to ±0.05 g, significantly improving product quality and consistency.

Intelligent Linkage and Process Optimization: The checkweigher connects to the MES system via RS485/Ethernet, enabling real-time adjustments to upstream filling equipment parameters, such as fill volume. This intelligent linkage improves production efficiency and reduces defect rates caused by equipment failures or process fluctuations. In practice, a chemical company, by integrating the checkweigher with the MES system, reduced its defect rate from 10% to 2% and increased production efficiency by 15%.

Durability and Adaptability: Featuring a stainless steel body with an IP65/IP69K protection rating, the checkweigher is designed to withstand the humid and corrosive environments typical of powder filling lines. Its brushless motor design enhances durability while reducing energy consumption by 20%, saving on operating costs.

IPv6 network supported

IPv6 network supported