Tablet Deduster

| Product Name | Automatic Tablet Deduster |

| Output | 500,000 pcs/h |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Pharmaceutical Tablet Deduster Introduction and Selection Guide

Tablet deduster machine introduction and application scenarios

Tablet dust removal machines are critical equipment in the final stages of tablet production. They are primarily used to remove dust and fine powder from the tablet surface after compression. They also physically remove burrs and other burrs from the edges, ensuring the tablets' appearance is neat and clean. Their core function lies in the quality control link between the tablet press and packaging machine, directly impacting the appearance qualification rate (typically required to be ≥99.5%) and the risk of dust contamination during subsequent packaging.

Application scenarios cover all tablet production fields: ordinary tablets can use the equipment to remove excess lubricant dust (such as magnesium stearate residue) generated during the tablet pressing process; sustained-release tablets need to use it to remove particle debris on the surface of the tablet before coating; in the production of effervescent tablets, the equipment can prevent packaging seal failure caused by dust; Chinese medicine tablets can use the equipment to solve the problem of extract powder easily adhering to the surface.

Core structure of Automatic Tablet Deduster

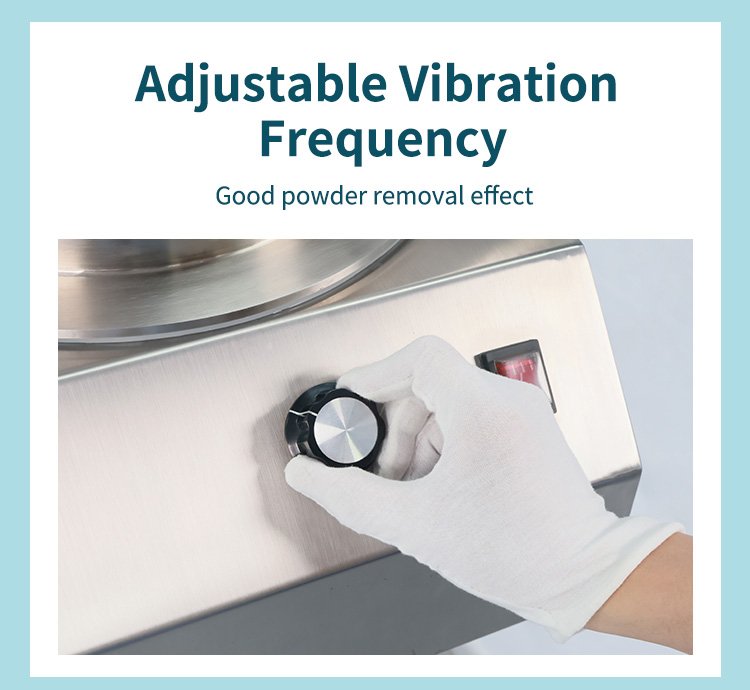

1. Feeding System : A tilted buffer hopper design and an adjustable-speed vibrating feeder (frequency 50-300Hz) ensure uniform tablet delivery into the processing chamber, preventing damage caused by accumulation and squeezing. High-end models feature a magnetically controlled feed valve, enabling production linkage with the upstream rotary tablet press.

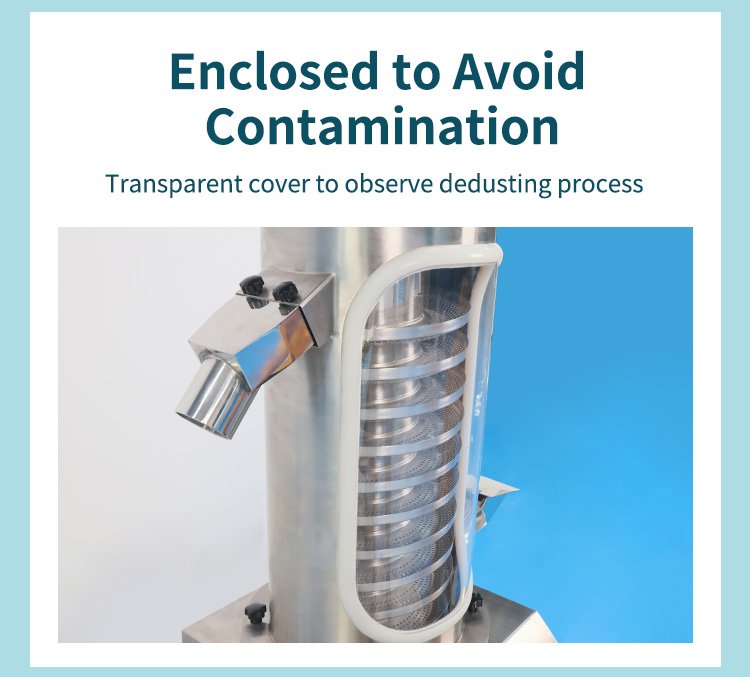

2. The processing chamber's core consists of a removable spiral track or vibrating screen. The spiral track is injection-molded from Celanex FDA-approved material, with a surface roughness of Ra ≤ 0.4μm. It uses vertical lifting motion to achieve tablet rotation and friction. The vibrating chamber utilizes a 316L stainless steel screen (pore size 0.5-1mm) with an adjustable screen angle (5-15°).

3. Deburring module : Built-in food-grade nylon brush or silicone scraper, with contact pressure of ≤0.5N on the tablet, removes edge burrs through flexible friction. The hardness of the brush is controlled at Shore 60-70A to balance the deburring effect and tablet protection.

4. Dust Removal System : Consisting of a negative pressure blower (1500-3000Pa), a HEPA filter (filtration efficiency ≥99.97% @ 0.3μm), and a dust collection box, this system creates a slightly negative pressure environment (-5 to -15Pa) within the chamber, effectively extracting any falling dust. Some models also feature an integrated metal detector to simultaneously remove tablets containing iron.

Common types and working principles of Tablet Dedusters

Tablet Deduster Machines are mainly divided into four categories, each with different working principles, core advantages, and applicable scenarios:

The first type is a vertical spiral type, which uses stepless vibration to drive the tablets up a spiral track, and uses gravity to flip the tablets and friction on the track to achieve dust and hair removal. Its core advantage is that it occupies a small area (≤0.5㎡) and processes the tablets evenly, making it suitable for small and medium-sized batch production (≤100,000 tablets/h).

The second type is the horizontal vibrating type, where the horizontal screen surface vibrates in three dimensions (amplitude 2-5mm). The tablets are released from dust during the bouncing process. This type has a large processing capacity (up to 300,000 tablets/hour) and is easy to clean, making it suitable for high-speed continuous production lines.

The third type is airflow-assisted, which combines vibration flipping with directional airflow (wind speed 10-15m/s) to enhance dust separation, with a dust removal efficiency exceeding 99.5%, and is mainly used for processing high-dust and sticky tablets;

The fourth type is a combination type, which integrates the triple functions of spiral pre-dust removal, brush finishing and metal detection, and can achieve one-stop quality control, which is suitable for high-end preparation production.

Core Guide to Tablet Deduster Selection

Material property adaptation principle

1. Tablet physical properties :

◦ In terms of hardness, brittle tablets with a hardness of ≤3kg (such as traditional Chinese medicine tablets) should choose a low-amplitude model (≤2mm) to avoid airflow-type fragmentation.

◦ In terms of shape, special-shaped pieces (such as elliptical and triangular) require customized track cross-sections to ensure sufficient flipping;

◦ In terms of surface properties, sugar-coated tablets should use silicone contact parts to avoid scratches, while plain tablets can use nylon brushes to improve the depilatory effect.

2. Dust characteristics :

◦ For sticky dust (such as those containing extract ingredients), a high-frequency vibration (≥200Hz) + hot air auxiliary (40-50℃) system is required;

◦ For ultrafine dust (<10μm), the HEPA filter grade needs to be confirmed, and it is recommended to use a filter element of H13 grade or above.

Matching production capacity and process

1. Processing capacity calculation : select the rotary tablet press machine based on 1.2 times of its maximum production capacity. For example, a tablet press with a capacity of 400,000 tablets/h needs to be equipped with a dust collector with a capacity of 480,000 tablets/h.

2. Space adaptation :

◦ For compact workshops, vertical spiral type is preferred (height ≤ 2.5m);

◦ The assembly line layout needs to confirm that the height of the inlet and outlet (usually 750-1000mm) matches the front and rear equipment.

3. Cleanliness level requirements:

◦ Class A/B clean area: A fully enclosed structure is required, the inner surface is electrolytically polished (Ra≤0.4μm), and SIP sterilization is supported;

◦ C/D grade clean area: Conventional 316L stainless steel models can be used, with CIP cleaning interface.

Key indicators of cGMP compliance

◦ Material: The parts in contact with drugs must be made of 316L stainless steel or FDA-certified engineering plastics. 304 stainless steel is prohibited.

◦ Design: No blind spots for cleaning (corner R ≥ 3mm), all parts can be disassembled and cleaned within 30 minutes;

◦ Verification support: Provide DQ/IQ/OQ documents, including dust residue detection methods (such as wiping method ≤ 0.1mg/㎡).

Common Misunderstandings and Key Points to Avoid in Tablet Screening Machine Selection

1. Misconception 1: Excessive pursuit of high speed to improve efficiency

Risk: A rotation speed exceeding 300Hz will cause the tablets to collide with each other and the breakage rate will increase to over 1%;

Solution: Increase productivity by increasing the contact area (e.g. by lengthening the spiral track) rather than increasing the rotational speed.

2. Misconception 2: Ignoring secondary pollution caused by dust collection

Risk: Ordinary bag filters can cause dust emissions to exceed the standard (>5mg/m³);

Verification method: Manufacturers are required to provide CNAS-certified dust emission test reports to ensure compliance with the new standard of 0.5mg/m³.

3. Myth 3: Clean design only depends on whether it is quick to disassemble

Key verification points: Check whether there is a powder-retaining structure at the joints of the spiral track, and require the sieving machine manufacturer to conduct a pigment residue test (residue after cleaning <0.01mg/㎡).

4. Misconception 4: Ignoring linkage with downstream equipment

Correct model selection: High-speed rotary tablet press production lines need to select models with Profinet/EtherCAT communication interfaces to achieve closed-loop speed control with the packaging machine.

IPv6 network supported

IPv6 network supported