Plastic Ampoule Filling Sealing Machine

| Product Name | Plastic Ampoule Filling and Sealing Machine |

| Precision | ± 0.1ml |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

The Ultimate Guide to Plastic Ampoule Filling and Sealing Machine: Application, Workflow, and Precision

Plastic ampoules, due to their lightweight, drop-resistant design, strong barrier properties (some materials include a barrier layer), and ease of aseptic packaging, have become a key choice for packaging small-dose materials in the pharmaceutical, cosmetics, and food industries. These ampoules typically range in volume from 0.2 to 10 ml and must precisely contain liquids, semi-fluids, or lyophilized powders. Because plastic ampoules undergo an integrated process of "plastic molding - precision filling - hermetic sealing," and the packaging materials often have stringent requirements for sterility, dosage accuracy, and sealing (such as vaccines in the pharmaceutical industry and active essences in the cosmetics industry), filling and sealing equipment presents a dual challenge: ensuring dimensional accuracy after molding (e.g., volume deviation ≤1%) while maintaining a tolerance of within ±2% of the filled dose. Furthermore, ensuring no leakage or deformation at the seal ensures safe storage and use of the material.

Suppository Packing Machine Packageable Materials and Industry Applications

The compatibility of plastic ampoules (e.g., PP, PETG, COP, etc.) and their barrier properties allow them to package a wide variety of materials, resulting in widespread application across multiple industries. Specifically:

In the pharmaceutical and healthcare industry, these materials encompass a wide range of forms by liquid blister packing machine: liquids include vaccines, biologics, antibiotic solutions, eye drops, and oral drops (e.g., vitamin D3 drops); semi-fluids include ointments and wound repair gels; and freeze-dried powders include protein drugs and stem cell preparations. The core requirements for plastic ampoules in this industry are sterility, absolute dosage accuracy, and a seal to prevent microbial contamination. Some materials also require an inert gas atmosphere to prevent oxidation. In the cosmetics, beauty, and daily necessities industries, plastic ampoules are suitable for a variety of highly active or low-dose materials. Liquids include hyaluronic acid concentrate, retinol concentrate, car perfume, and ampoule toners and rose oil. Semi-fluids include face cream samples and mask essences. Freeze-dried powders include freeze-dried mask active ingredients and anti-aging freeze-dried powders. Key requirements for this industry are preventing ingredient oxidation (relying on the ampoule's oxygen barrier properties) and contamination (to meet single-use requirements). Furthermore, the ampoule's appearance must be pristine, free of scratches or seal deformation.

In the food and health industry, plastic ampoules made by automatic plastic ampoule packing machine are used to package concentrated nutrient solutions such as probiotic drops, DHA algae oil, and vitamin B12 oral solution; semi-fluids include honey samples and jam concentrates; and powders include nutritional supplements such as infant lactoferrin powder. Core requirements for this industry are that the materials used meet food safety standards (such as FDA and GB 4806), exhibit moisture barrier properties, and enable controlled dosage to meet single-use requirements.

Plastic Ampoule Filling and Sealing Packaging Machine Workflow

The core process is the integrated "forming - filling - sealing" process, which must be adapted to the thermal processing characteristics of the plastic material. The complete process chain is as follows:

Mold Preparation:

Preheat the mold (mostly multi-cavity) to 80-120°C to ensure uniform molding of the plastic film upon contact with the mold. Plastic Ampoule Forming:

Plastic film is squeezed into the preheated mold cavity through the extruder head. A blow molding device (low-pressure air blowing, 0.3-0.5 MPa) forces the melt to adhere to the mold walls, forming the ampoule prototype (including the bottle body and neck structure).

Cooling water (15-25°C) is introduced to cool the mold, allowing the plastic to quickly cool and set (cooling time 10-30 seconds, adjusted according to bottle thickness), ensuring a stable bottle shape and precise volume.

Ampoule Positioning and Aseptic Processing (optional):

After forming, the empty ampoule is transported via a conveyor to an aseptic station (for the pharmaceutical and food industries) for disinfection with ultraviolet light or hydrogen peroxide spray to ensure sterility.

A mechanical positioning device (such as a servo motor-driven gripper) secures the ampoule, ensuring precise alignment of the neck with the filling head and sealing device (positioning error ≤ 0.1mm), preventing subsequent leakage or misalignment during filling. Quantitative Filling:

Select the appropriate filling system based on the material form (liquid/semi-fluid/powder): liquids use a peristaltic pump or servo plunger pump (minimum filling volume 0.1ml, accuracy ±0.5%), semi-fluids use a screw pump (to prevent wall buildup), and powders use a negative pressure suction powder filling device.

Insert the filling head into the bottle mouth (or use non-contact filling to avoid contamination) and inject the material according to the preset dosage. A liquid level sensor monitors the filling volume in real time, and the system will be stopped and adjusted immediately if abnormalities occur. Sealing and Curing:

After filling, the ampoule is delivered to the sealing station, where heat sealing or ultrasonic sealing is used depending on the plastic material:

▪ Heat sealing: A heated seal head (180-220°C) presses against a pre-set sealing film (such as aluminum-plastic composite film) at the bottle neck for 2-5 seconds to achieve a seal. This is suitable for PP and PETG materials.

▪ Ultrasonic sealing: 20-40kHz ultrasonic vibrations melt the plastic at the bottle neck, eliminating the need for contact heating. This results in a smoother seal (seal strength ≥ 50N/15mm) and is suitable for applications requiring high precision.

After sealing, the bottle is rapidly cooled by a cooling fan (ambient air) to prevent deformation at the seal. Precision Control for Plastic Ampoule Filling and Sealing Packaging Machines

Through coordinated precision throughout the entire "molding-filling-sealing" process, this machine achieves filling and molding accuracy within ±2%. The core control features are as follows:

PLC + Servo Motor Dual Control System:

Suppository filling machine using an industrial-grade PLC (such as the Siemens S7-1200) as the core, parameters such as molding temperature, filling volume, and sealing pressure are preset. 10+ sensors (temperature, pressure, and displacement) simultaneously collect real-time data. For example, if the plastic melt temperature fluctuates by more than ±2°C, the heating power is automatically adjusted. If the filling pressure is abnormal, the pump valve opening is adjusted in real time to prevent dosage deviations.

Servo motors drive mold opening and closing, conveyor belt movement, and filling head movement, with speed control accuracy of 0.01 rpm. This ensures perfect synchronization of molding, filling, and sealing speeds, preventing underfilling or misaligned sealing caused by ampoule positioning deviations. Precision Molding and Filling Components:

Molding Molds of automatic ampoule forming filling sealing machine: Utilize P20 plastic mold steel, with cavity dimensional accuracy controlled to ±0.02mm (ensuring ampoule volume deviation ≤1%) and cavity surface roughness Ra ≤0.4μm to minimize plastic adhesion. The molds are also equipped with venting slots (0.1-0.2mm in diameter) to expel trapped air from the cavity and prevent bubbles in the bottle from affecting volume accuracy.

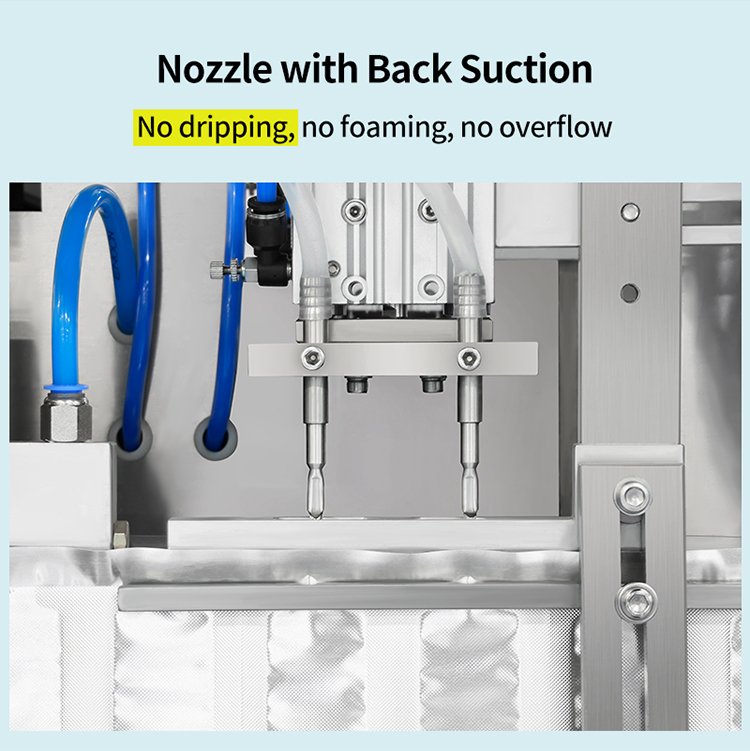

Filling Pumps and Valves: The pharmaceutical industry prefers peristaltic pumps (silicone tubing in contact with the material, eliminating cross-contamination and enabling easy replacement), with a minimum adjustment accuracy of 0.001ml. For high-viscosity materials, servo screw pumps (pitch error ≤0.01mm) are used to ensure stable delivery rates. Pump and valve outlets are equipped with anti-drip devices (such as solenoid-controlled stop valves) to prevent dripping after filling and excessive dosage.

Summary

High precision is the core value of the plastic ampoule filling and sealing packaging machine. It not only directly determines the dosage accuracy of small-dose materials, but also becomes a key equipment for small-dose material packaging in industries such as medicine, cosmetics, and food through full-process precision control and flexible material adaptability.

IPv6 network supported

IPv6 network supported