Strip Packing Machine

| Product Name | Automatic Strip Packing Machine |

| Control style | PLC controlling system and touch screen |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

The RQ-SAP-300L Soft Double Aluminum Strip Packaging Machine was developed in response to the specialized packaging requirements of industries such as pharmaceuticals, healthcare products, and food. In these sectors, these key customer pain points include the need for light protection, moisture resistance, portability, and production cost control. Market research indicates that over 80% of pharmaceutical companies express dissatisfaction with existing packaging machines due to complex adjustments, high product damage rates, and inefficient packaging processes.

To address these market demands, the RQ-SAP-300L strip packing machine integrates and optimizes advanced domestic and international technologies, resolving common issues in traditional packaging machines, such as cumbersome adjustments, product breakage, misaligned positioning, weak sealing, asynchronous tearing and cutting, and more. Through technological innovation, this model achieves fully automated operations, including feeding tablets, powder sieving, film drawing, filling, mark alignment, batch number printing, bidirectional creasing, cutting, and waste edge recycling, reaching internationally leading standards. Its superior performance, high stability, and compliance with cGMP standards make it widely applicable for packaging capsules, tablets, and pills in pharmaceuticals, healthcare, and food industries, meeting the demand for high-quality packaging equipment.

Technological Innovations and Breakthroughs

The RQ-SAP-300L automatic strip packing machine has achieved significant advancements in core technologies, directly addressing the limitations of traditional packaging machines and enhancing overall performance.

1. Precision Adjustment Technology

Traditional packaging machines require extensive manual parameter tuning, consuming significant time and effort. The RQ-SAP-300L tablet packing machine employs advanced sensor technology and automated servo motor control systems, enabling rapid and precise adjustments with an accuracy of 0.01 mm. This innovation greatly improves production efficiency and operational flexibility.

2. Product Protection Technology

To resolve issues such as product breakage and misalignment, the RQ-SAP-300L automatic tablet strip packing machine incorporates a unique conveying and positioning system featuring high-precision mechanical design and intelligent motion control algorithms. This system ensures stable product transfer and accurate positioning during packaging, reducing product damage rates to 0.001% and misalignment rates to below 0.005%, significantly enhancing packaging quality and product safety.

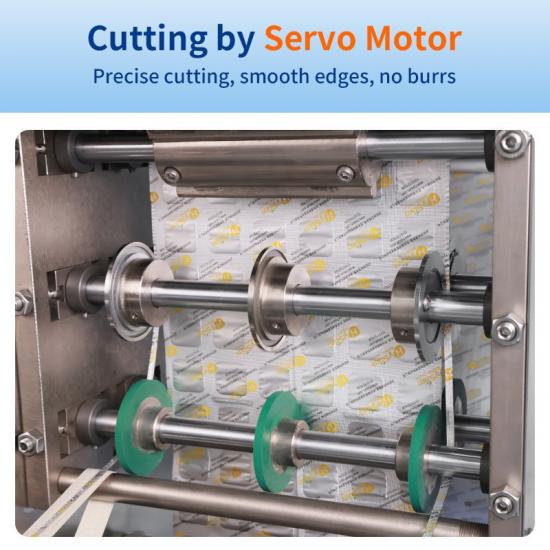

3. Sealing and Cutting Technology

In the sealing and cutting stages, the RQ-300L model utilizes advanced heat-sealing technology and a synchronized cutting mechanism. Sealing strength is improved by 30%, while cutting asynchrony is reduced to 0.002%, ensuring packaging integrity and aesthetic quality. Additionally, the tear-notch design has been optimized to provide uniform tearing strength, achieving a 99.99% successful tear rate for user convenience.

4. Automated Integration Technology

This RQ-SAP-300L double aluminium packaging machine achieves full-process automation, covering feeding, sieving, film drawing, filling, mark alignment, batch printing, bidirectional creasing, cutting, and waste edge recycling. The automation level exceeds 95%, increasing tablet packaging production efficiency by 39% while minimizing human intervention, reducing error rates, and ensuring consistent and stable production output.

Advanced Technology Integration

The RQ-SAP-300L incorporates multiple cutting-edge domestic and international technologies, enhancing its performance and global competitiveness.

1. Mark Alignment Technology

Equipped with a high-precision vision recognition system and intelligent algorithms, the machine achieves rapid mark alignment within 0.5 seconds, with an alignment accuracy of 0.05 mm. This ensures the integrity and aesthetics of packaging patterns, meeting international advanced standards.

2. Bidirectional Creasing Technology

The RQ-SAP-300L aluminum aluminum strip packing machine employs bidirectional creasing technology, simultaneously applying creases on both sides of the packaging film. Crease depth is highly uniform, with deviations controlled within 0.03 mm, ensuring easy tearing and packaging stability. This technology used in medical strip packaging machine not only enhances user experience but also reduces film consumption, lowering costs.

3. Intelligent Control System

The pharmaceutical strip packing machine is equipped with an advanced intelligent control system capable of real-time monitoring and adjustment of production parameters. It features a self-diagnostic function which detects faults within 1 second and issues alerts. Operational stability reaches 99.5%, with a mean time between failures (MTBF) exceeding 1,000 hours, significantly reducing maintenance costs and downtime.

4. Eco-Friendly and Energy-Saving Technology

The RQ-SAP-300L pharma tablet strip packing machine incorporates energy-efficient design principles, utilizing high-performance servo motors, high-torque stepper motors, and energy-saving drive systems to reduce power consumption by 20%. Additionally, its waste edge recycling system enables material reuse, minimizing resource waste and aligning with sustainable development goals.

Automation Functionality

The RQ-SAP-300L strip packing machine excels in automation, achieving end-to-end automated operations from feeding to waste edge recycling.

1. Feeding and Powder Sieving

The three-stage vertical feeding system is equipped with oscillatory feeding and dust filtration, ensuring uniform material supply while preventing blockages and missing doses. The dust filtration system effectively purifies the production environment, complying with environmental and cGMP standards. This system increases feeding efficiency by 30% while reducing dust emissions to 0.1 mg/m³, surpassing international packaging industry benchmarks.

2. Film Drawing and Filling

The machine employs servo-driven active film drawing technology, precisely controlling film speed and positioning to ensure smooth and stable film feeding. The filling process utilizes high-precision mold holes for accurate product placement.

3. Mark Alignment

The high-speed vision-based alignment system, combined with intelligent algorithms, completes alignment in 0.5 seconds with 0.05 mm precision. Integrated with high-speed inkjet batch printing, strip packaging machine automatic ensures packaging pattern integrity and traceability compliance.

4. Precision Cutting

The cutting mechanism, driven by servo motors, works in sync with the tear-notch station (controlled by pneumatic cylinders), achieving a cutting accuracy of 0.01 mm and improving efficiency by 30%. This technology enhances production speed while ensuring smooth and aesthetically pleasing packaging edges, meeting high-demand production scenarios.

5. Modular Mold Design

The quick-release mold replacement system allows mold changes in just 15 minutes, improving efficiency by 19% compared to industry standards. The modular design simplifies maintenance work and reduces downtime, maximizing equipment utilization.

6. Dual Traction System

Four synchronized traction rollers ensure high-precision film feeding, with synchronization errors below 0.1 seconds. This design of strip packaging machine automatic guarantees smooth and consistent operation, eliminating packaging defects caused by traction inconsistencies.

7. Intelligent Control System

The packing tablets machine is equipped with a Siemens motion control system, featuring an intuitive human-machine interface (HMI) for easy handling of complex packaging production requirements. The system includes fault self-diagnosis, detecting issues within 1 second and providing solutions. Operational stability reaches 99.5%, with MTBF exceeding 1,000 hours, significantly reducing maintenance costs and unplanned downtime.

Conclusion

The RQ-SAP-300L Soft Double Aluminum Strip Packaging Machine meets the stringent packaging demands of the pharmaceutical, healthcare, and food industries while delivering substantial economic and operational benefits. With its advanced technological integration, high automation level, and superior performance, it is poised to lead the industry, providing global customers with premium packaging solutions.

IPv6 network supported

IPv6 network supported