V Type Mixer

| Product Name | V type Mixer Machine |

| Capacity | 10-50 kg/batch |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

V type mixer selection guide: a complete analysis from parameters to industry adaptation

V type mixers, as core equipment for mixing powders and granular materials, are widely used in the pharmaceutical, food, chemical, and new energy industries. Their unique V-shaped barrel design achieves three-dimensional material movement through asymmetrical rotation, resulting in highly uniform mixing and minimal dead zones. However, improper selection can lead to problems such as low mixing efficiency, material contamination, and equipment loss. This article will provide scientific selection recommendations based on key parameters, industry compatibility, and avoiding selection pitfalls, helping companies accurately match production needs.

Core parameters of model selection: first clarify the 6 key indicators of the V type mixer

Before selecting a model, you need to determine the following core parameters based on material properties and production requirements. This is the basis for ensuring the adaptability of the equipment.

Effective volume: Match production batch

The effective volume of a V type powder mixer is usually 40%-60% of the total volume of the equipment (for special materials such as materials that are prone to agglomeration, the effective volume needs to be reduced to 30%). When selecting a model, the feed amount of each batch of materials must be taken into consideration.

For example: If 80L of material needs to be mixed in each batch, the effective volume needs to meet 80L / 50% which is 160L. You should choose equipment with a total volume of 200L (reserving a safety margin).

Common specifications recommended:

· Laboratory /pilot production : 10L-50L (such as prescription verification in pharmaceutical R&D)

· Pilot / small-scale production: 100L-300L (e.g. small batch mixing of food additives)

· Large-scale production: 500L-2000L (such as large pharmaceutical factories or large-scale production )

Mixing uniformity: select the structure configuration according to the material requirements

Different industries have significantly different requirements for mixing uniformity, which needs to be achieved through equipment structure optimization:

· High-demand scenarios (such as pharmaceutical powder materials): Choose a V type powder mixing machine equipped with a forced stirring device and install a stirring paddle in the barrel to improve the uniformity to over 99.5%, avoiding stratification of materials with large density differences.

· For common demanding scenarios (such as plastic pellets and feed), a standard V-shaped structure can meet the requirements, and the uniformity can reach 95%-98%.

Material characteristics: Targeted solutions to problems of viscosity, corrosiveness, flammability and explosion

The physical and chemical properties of the material directly determine the material and structural design of the automatic V shape mixer:

|

Material properties |

Adaptation Solution |

|

sticky materials |

Choose inner wall polishing (roughness Ra ≤ 0.8μm) + detachable stirring paddle to avoid material adhesion; add air hammer device to assist material shedding. |

|

Corrosive materials |

The contact material is 316L stainless steel (acid and alkali resistant), and the seal is made of fluororubber (chemical corrosion resistant). |

|

Flammable and explosive materials |

It adopts explosion-proof motor + electrostatic grounding device, and the barrel body avoids sharp angle design to reduce the generation of friction static electricity. |

|

Heat-sensitive materials |

An optional V-shaped barrel with a jacket can be used to pass cold water or low-temperature medium to control the temperature and avoid material temperature rise and deterioration during the mixing process. |

Speed and power: balancing efficiency and energy consumption

· Speed Selection : The main shaft speed of a standard pharmaceutical V type mixer is 15-30 rpm. Too high a speed can easily cause centrifugal separation (especially for materials with large density differences), while too low a speed can prolong mixing time. A variable frequency motor can be used to adjust the speed to suit different materials.

· Power matching : Estimated based on equipment volume. For example, a 100L unit has a power of approximately 1.5-2.2kW, a 500L unit has a power of approximately 4-5.5kW, and a 1000L unit has a power of approximately 7.5-11kW. Note: For viscous materials or high fill rates, the power may need to be increased appropriately (allowing a 20%-30% margin).

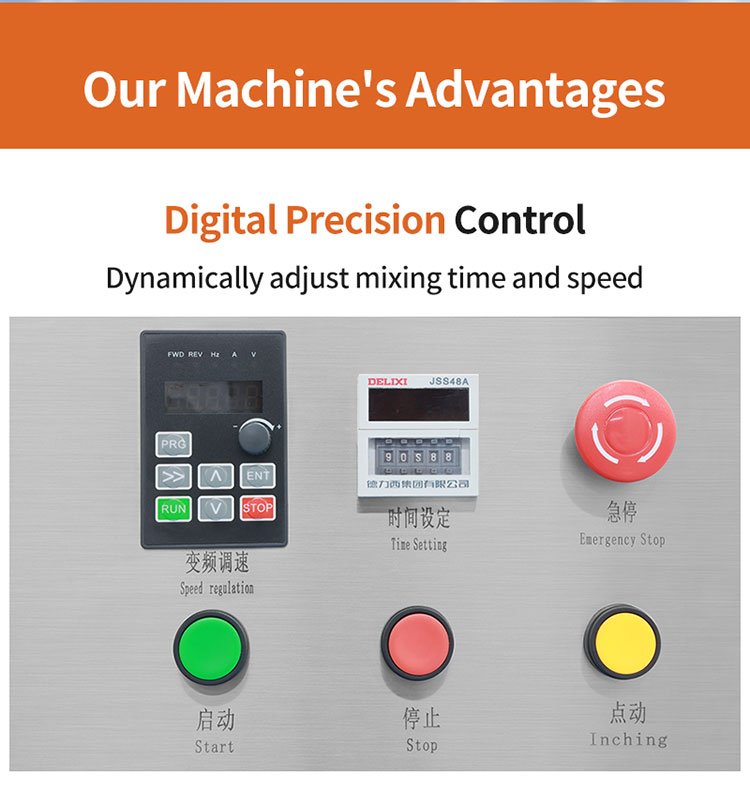

Automation level: From manual to intelligent

· Basic type : manual feeding / discharging, mechanical timer controls mixing time, suitable for small batches and simple material mixing (such as laboratories).

· Semi-automatic type : Pneumatic or electric control of the discharge valve, PLC control of mixing time and speed, can be connected to a loader for automatic feeding, suitable for medium-scale production (such as small and medium-sized pharmaceutical and health care product factories).

· Intelligent V mixer machine for powder: Equipped with a touch screen human-machine interface, it can store 100+ recipe parameters, monitor mixing temperature, speed, current and other data in real time, support MES system docking, and is suitable for high-precision, multi-variety production (such as large-scale pharmaceutical c GMP workshops).

Hygiene requirements: Special considerations for the pharmaceutical and food industries

If the automatic mixer purchased is used in the pharmaceutical, health care product, food and other industries, it must comply with cGMP, FDA and other regulatory requirements:

· Material: The part in contact with the material must be 316L stainless steel, with no dead angles and no threaded connections (using quick-release clamps) for easy cleaning.

· Cleaning function: An optional cleaning-in-place (CIP) system can automatically clean the inner wall of the barrel through a spray ball to avoid cross contamination.

· Verification support: Provide material certification, surface roughness test reports, and cleaning validation plans to meet the audit requirements of the pharmaceutical, health care, and food industries .

Industry-specific recommendations: The best solutions for different mixing scenarios

The production requirements and material properties of different industries vary greatly. The following are targeted automatic powder mixing machine selection suggestions:

Pharmaceutical industry: compliance and high precision first

· Core requirements: compliance with c GMP regulations, no cross contamination, and high mixing uniformity (RSD ≤ 2%).

· Recommended model: Pharmaceutical or food grade V type mixer

· Material: Contact part is 316L stainless steel, inner wall is electrolytically polished (Ra≤0.4μm), and the outer wall is 304 stainless steel wire drawing.

· Structure: detachable stirring paddle (easy to clean), quick-install inlet and outlet, and seals made of food-grade silicone rubber.

· Additional functions: Equipped with differential pressure level meter (to avoid overload), automatic recording of mixing process data (for easy traceability).

· Application case: A pharmaceutical company produces cephalosporin powders and uses a 200L sanitary V type mixer, equipped with a vacuum loader and a CIP system. The mixing uniformity RSD is 1.5%, meeting c GMP certification requirements.

Food industry: balancing hygiene and efficiency

· Core requirements: no material residue, easy to clean, and adaptable to a variety of materials (such as powders, granules, and pellets).

· Recommended model: Standard sanitary V type mixer

· Material: Contact part is 304 stainless steel (food grade), inner wall is polished (Ra≤0.8μm), and seal is food grade fluororubber.

· Structure: Large-diameter discharge valve (to avoid material blockage), jacket design can achieve heating (such as powder drying) or cooling (such as chocolate powder mixing).

· Application case: A baking company mixes flour and additives using a 300L jacketed V type mixer, controlling the temperature at 25°C and mixing time for 15 minutes. The uniformity reaches 98%, and there is no residue after cleaning.

V Type Mixer Selection Mistakes and Avoidance Strategies: 5 Key Points to Avoid Pitfalls

Misunderstanding 1: Only look at the price and ignore the material and craftsmanship

· Problem: Cheap V -type mixers may use 201 stainless steel (prone to rust) or inferior seals (prone to leak). This may seem to save costs in the short term, but may lead to greater losses in the long term due to equipment failure or material contamination.

· Avoidance: Prioritize material certification (such as 316L stainless steel spectrum test report) and surface treatment technology (such as polishing accuracy) rather than simply comparing prices.

Misunderstanding 2: Excessive pursuit of large volume and ignoring the actual feed amount

· Problem: Choosing a volume that far exceeds actual needs (e.g., choosing a 200L machine when the actual batch size is 50L) results in too much space for the material to move in the barrel, prolonging the mixing time and increasing energy consumption.

· Workaround: Calculate the effective volume by “actual feed amount÷50%”, then select equipment with the corresponding total volume, and reserve a 10%-20% margin.

Misunderstanding 3: Ignoring material fluidity and blindly choosing standard models

· Problem: For materials with poor fluidity (such as ultrafine powders and sticky materials), a standard granule mixer without a stirring paddle is used , resulting in uneven mixing and material agglomeration.

· Avoidance: Inform the manufacturer of the material's angle of repose in advance (angle of repose > 45° indicates poor fluidity) and request a forced stirring device or special inner wall design (such as a guide plate).

Misunderstanding 4: Neglecting after-sales service and spare parts supply

· Problem: Some small powder mixer manufacturers do not have a complete after-sales system, and cannot repair equipment in time after failure, affecting production progress; spare parts (such as seals and stirring paddles) are not supplied in time.

· Avoidance: Choose a manufacturer that has been established for more than 10 years and has industry case studies, confirm the after-sales response time (e.g., within 20 hours), and request a list of commonly used spare parts and prices.

Misconception 5: Skip the test phase and go straight to purchase

· Problem: If the mixing machine is not tested with actual materials and the suitability is judged based solely on parameters, problems such as substandard mixing uniformity and material sticking to the wall may occur.

· Avoidance: Ask the manufacturer to provide trial machine service (materials can be sent to the manufacturer for trial machine), shoot trial machine video or provide mixing uniformity test report, and purchase only after confirming that it meets your needs.

Selection Process Summary: 4 Steps to Quickly Determine the Suitable Powder Mixer Model

Clarify requirements : determine the amount of material per batch, mixing uniformity requirements, material properties (viscosity, corrosiveness, flammability and explosiveness, etc.), and industry compliance standards (such as cGMP and FDA).

Parameter calculation : Calculate the effective volume based on the feed amount , select the material and structure (such as whether a stirring paddle or jacket is required) based on the material characteristics , and determine the speed and power.

Industry matching : Refer to the above industry recommendations to select models that meet industry needs.

Verification and Communication : Require the manufacturer to provide a trial run, material certification, after-sales support, and clearly define delivery dates and installation and commissioning services. These steps ensure that the selected V type mixer not only meets current production needs but also offers flexibility (such as variable frequency drive and scalable automation) to allow for future capacity increases or material changes.

IPv6 network supported

IPv6 network supported