Powder Filling Machine

| Product Name | Powder Filling Machine |

| Precision | ± 0.2g |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Rich Packing Powder Filling Machine Overview

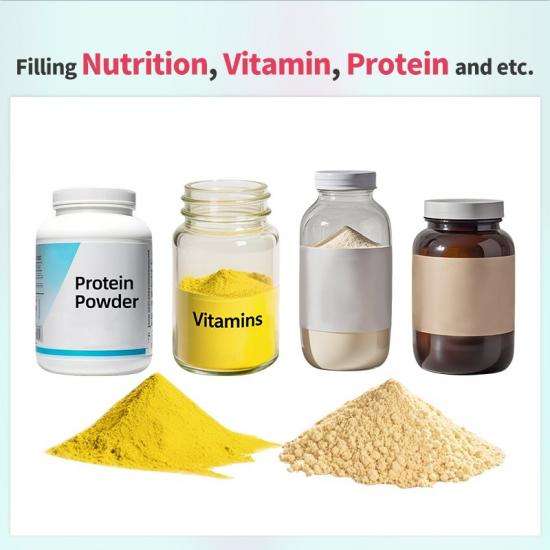

A automatic powder filling machine is an automated device specifically designed for the quantitative filling of powders and granular materials into containers. Utilizing a proprietary PLC system, it achieves high-precision packaging. Its core operating principle involves manually setting the desired powder fill volume, after which the PLC intelligently controls the servo motor to drive the screw feeding mechanism, completing the filling process. It is suitable for a wide variety of materials, including common powders, sticky powders with poor flow properties, hygroscopic powders, and highly soluble granules, such as pharmaceutical powders, protein powders, vitamin powders, and milk powder.

Advantages of Rich Packing Powder Filling Machines

Proprietary PLC System Control

The core operation of Rich Packing's fully automatic powder filling machine is governed by its proprietary PLC system. The PLC (Programmable Logic Controller) is central to achieving high-precision filling, precisely managing the entire filling sequence. The operator sets the target fill weight, and the PLC intelligently controls the servo motor that drives the screw feeder. This highly automated control system ensures stable and repeatable filling performance, with an accuracy error of ≤±0.01g, across a filling range from 2g to 1000g. This level of precision control is critically important in industries such as food, pharmaceutical, and chemical, as it guarantees consistent product quality, minimizes material waste, and enhances production efficiency.

High Accuracy Screw Metering Technology

The screw metering technology employed in Rich Packing's pharmaceutical powder filling machine is a core strength. By using the proprietary PLC system to precisely control the speed and rotation count of the servo motor-driven screw, the equipment achieves exceptional filling accuracy, with an error margin of ≤±0.01g. This industry-leading accuracy level accommodates filling ranges from 2g to 1000g, meeting diverse industry needs from food to pharmaceuticals. For instance, in pharmaceutical applications requiring extremely precise filling of medicinal powders, Rich Packing's high-precision screw metering ensures each bottle of powdered medicine is accurately dosed, meeting stringent production standards.

Servo Motor Automatic Compensation System

The servo motor automatic compensation system is another key feature of Rich Packing's granule powder packing filling machines. This system continuously monitors changes in material specific gravity and level, automatically correcting metering errors using precision Siemens® servo motors. This real-time compensation ensures stable filling accuracy even when material properties fluctuate during operation. For example, in the chemical industry, where powder specific gravity might vary due to humidity, the Rich Packing machine's automatic compensation system adjusts instantly to maintain uncompromised filling accuracy.

Furthermore, the high precision, rapid response, and exceptional reliability of the servo motors significantly enhance the overall stability and dependability of the machine. Application data demonstrates that this system effectively minimizes metering errors to very low levels, offering superior performance compared to similar products and providing users with highly reliable production assurance.

High-Speed Filling and Customization

Rich Packing packing powder filling machines offer significant competitive advantages through high-speed filling capabilities. A single filling head can achieve packaging speeds of 30-100 bottles per minute, an industry-leading rate that substantially boosts production efficiency for large-scale operations. In sectors like food and pharmaceuticals, this high-speed capability effectively shortens production cycles, reduces costs, and improves market responsiveness. Furthermore, Rich Packing supports the customization of additional filling heads to meet diverse production demands, enabling continuous operation at even higher speeds. This flexible customization service allows companies to select the optimal number and configuration of filling heads based on their specific production scale and product characteristics, achieving peak efficiency and cost-effectiveness.

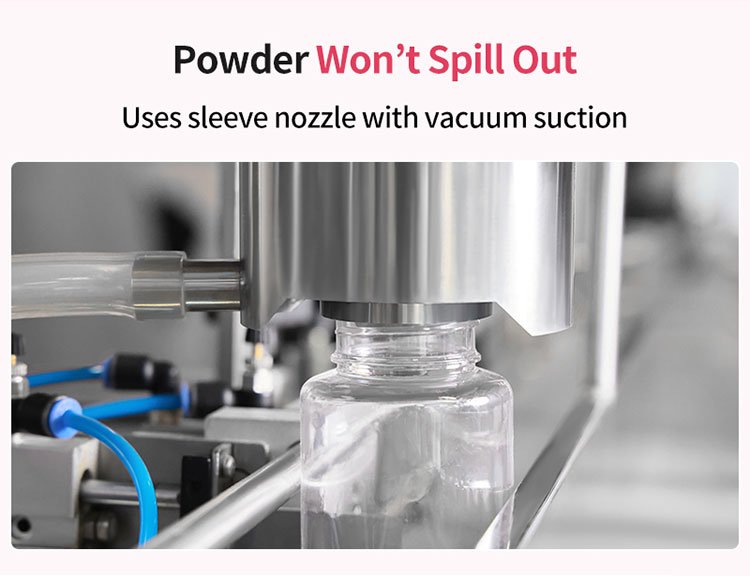

Dust Overflow Prevention

Rich Packing automatic packing filling machine for powder incorporate effective dust overflow prevention, a crucial feature for environmental control and operator safety. Utilizing a sleeve-type filling nozzle design equipped with a negative pressure dust re-suction device and employing a fast-initial/slow-final filling technique, the system minimizes the potential for powder spillage and dust generation during the filling process. This design not only significantly reduces airborne dust contamination, ensuring a cleaner and safer production environment, but also minimizes material waste and enhances overall production efficiency.

In practical applications, dust overflow prevention is particularly vital when handling hygroscopic powders or highly soluble granules. Rich Packing's dust control system effectively mitigates these issues, ensuring smooth and reliable production.

Integrated Packaging Production Lines

Rich Packing provides not only standalone dry powder filling machines but also comprehensive integrated powder packaging production line solutions. These lines incorporate various equipment, including bottle unscramblers, capping machines, and labeling systems, forming a complete, automated production flow. This integrated approach automates the entire process from raw material filling through to finished product packaging, significantly improving overall production efficiency and ensuring consistent product quality.

By offering complete powder packaging lines, Rich Packing delivers a one-stop solution, simplifying equipment procurement and installation, lowering operational costs, and enhancing both production efficiency and product quality. This holistic solution provides a significant competitive edge in the market and caters effectively to the diverse requirements of the food, pharmaceutical, and chemical industries.

Rich Packing's powder bottle filling machines, featuring advanced screw metering technology, servo motor automatic compensation, and dust overflow prevention, are widely applicable for filling both common and specialty powders. They deliver high-precision, high-efficiency, and high-safety filling solutions across food, pharmaceutical, and chemical sectors.

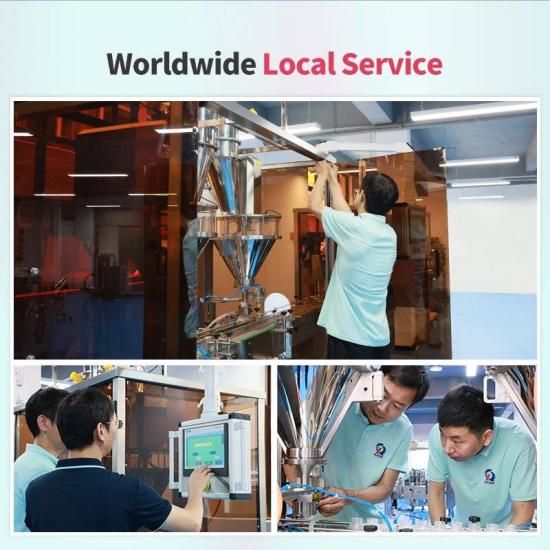

Rich Packing offers global sales and localized service support for its powder filling machines

Machine Installation and Commissioning

Rich Packing's global reach combined with localized service is a core strength. Our company provides professional powder filling packing mahine installation teams for customers worldwide. These teams possess extensive on-site experience and can efficiently install the equipment according to the customer's specific production environment and layout. Following installation, the team conducts thorough commissioning to ensure all equipment performance metrics are optimized, guaranteeing that filling accuracy and production speed meet or exceed design specifications.

Professional Operator Training

Rich Packing delivers comprehensive user training covering high speed filling powder packing machine operation, routine maintenance, and troubleshooting procedures. The training team comprises experienced engineers who are not only experts in the technical details of the equipment but also understand the production processes and operational standards of various industries. Training combines classroom instruction with practical, hands-on exercises, including on-site demonstrations and supervised operation, ensuring users gain proficiency. Rich Packing also supplies detailed training manuals and operational videos for ongoing reference after the training sessions.

Technical Support and User Manuals

Rich Packing provides users with an extensive suite of powder filling machine technical documentation, including Installation Manuals, Operation Manuals, Maintenance Guides, and Troubleshooting Tutorials. These materials thoroughly detail the equipment's structural principles, step-by-step operating procedures, critical maintenance points, and common fault resolution methods, serving as a comprehensive reference. For example:

The Installation Manual details processes such as foundation setup, electrical connections, and commissioning procedures, along with essential precautions.

The Operation Manual covers startup, operation, shutdown sequences, and parameter configuration details.

The Maintenance Guide provides schedules and methodologies for preventative maintenance, helping users maximize equipment lifespan and operational efficiency.

Rich Packing regularly updates these materials to reflect technical enhancements and evolving industry standards, ensuring users always have access to the latest and most accurate information.

IPv6 network supported

IPv6 network supported