Liquid Filling Machine

| Product Name | High Precision Liquid Filling Machine |

| Precision | ± 0.1ml |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

In modern industrial production, the efficiency, precision, and stability of the liquid filling process directly affect product quality and enterprise production efficiency. Rich Packing liquid filling machine, with its excellent performance, has become an ideal choice for liquid filling production in various industries such as pharmaceuticals, health products, food, and chemicals, providing efficient, accurate, and reliable solutions for the filling of various liquid materials.

Strong Compatibility, Adapting to Diversified Production

One of the most prominent advantages of Rich Packing liquid filling bottling machine is its strong compatibility. It can easily meet the filling needs of different types of liquid materials in various industries, and at the same time, it is compatible with multiple containers, showing broad application potential in diversified production scenarios.

From the perspective of liquid materials, it can perfectly adapt to various liquids such as syrup, eye drops, and oral liquids. In the pharmaceutical industry, the filling liquid machine can operate stably for liquid medicines with different compositions and concentrations, ensuring the safety and hygiene of the filling process. In the health product industry, Rich Packing liquid packing filling machine can also handle various nutritional liquids, health syrups, etc., which have different characteristics such as viscosity and acidity. In the food industry, fruit juices, sauces, edible oils, etc., and in the chemical industry, various liquid reagents, lubricants, etc., can also be efficiently filled by this filling machine.

In terms of container adaptation, its performance is also excellent. By replacing the filling system, it can fill a variety of containers, whether it is small-caliber bottles, such as the narrow-mouth bottles for eye drops and small glass bottles for oral liquids, or bottles of ordinary caliber sizes, such as cough syrup in medicines, it can accurately match. This strong compatibility enables enterprises to avoid purchasing separate equipment for different materials and containers, greatly reducing the equipment investment cost of enterprises, and at the same time reducing production caused by equipment replacement, improving the continuity and flexibility of production.

It is this excellent compatibility that allows liquid bottling machine to play a significant role in industries such as pharmaceuticals, health products, food, and chemicals, meeting the diversified filling needs of different industries and becoming a powerful assistant in the production lines of many enterprises.

Precise Filling with Minimal Error

In liquid filling production, precision is one of the key indicators to measure equipment performance, especially in industries with extremely high dosage requirements, even a tiny error may cause serious consequences. Rich Packing liquid oil filling machine performs excellently in precise filling, fully meeting the strict requirements of various industries for filling precision.

The filling machine adopts a servo motor to drive the feeding pump, and this advanced driving method provides a solid technical guarantee for high-precision filling. Servo motors have the characteristics of fast response speed, high control precision, and stable operation, which can accurately control the rotation speed and running time of the feeding pump, thereby realizing precise control of the filling volume. In practical applications, the filling error is ≤±0.1ml, and such high precision is in a leading level among similar equipment.

In the pharmaceutical industry with high precision requirements, this high-precision performance is particularly important. For example, in the filling of eye drops, the dosage of each drop has strict regulations, and excessive error may affect the efficacy of the medicine and even pose a risk to the patient's eye health. Automatic liquid filling machine can ensure that the dosage of each bottle of eye drops is accurate, providing a strong guarantee for the quality of medicines. In the production of oral liquids, precise dosage control is also required to ensure that patients can take the correct dosage to achieve the therapeutic effect.

Moreover, in the health product industry, for some high-value nutritional liquids, the accuracy of their dosage is directly related to the efficacy of the product and cost control. Precise filling can avoid cost waste caused by excessive dosage, and also prevent the decline in product efficacy caused by insufficient dosage. In the chemical industry, for the filling of some chemical reagents, precise dosage is an important prerequisite for ensuring the accuracy of experimental results and production safety. The high-precision filling of Rich Packing liquid filling machine undoubtedly provides reliable support for the production of these industries.

Unique Filling Methods to Reduce Liquid Loss

CE liquid filling machine adopts two unique filling methods, which effectively reduce liquid loss while ensuring the quality of filling.

Bottom diving filling is one of its major features. During the filling process, the filling head is always kept below the liquid level. This design cleverly solves the problem of liquid foaming and splashing. For some easy-to-foam liquids, such as liquids containing surfactants and certain oral liquids, the traditional filling method is easy to fill above the liquid level, causing violent contact between the liquid and air, resulting in a large number of bubbles. These bubbles not only occupy the container space, affect the accuracy of the filling volume, but also may overflow the container, causing liquid waste and equipment pollution. However, with bottom diving filling, since the filling head goes deep below the liquid level, the liquid can be smoothly injected into the container, greatly reducing contact with air, and fundamentally inhibiting the generation of bubbles. At the same time, it also avoids the liquid splashing out of the container due to impact, further reducing liquid loss.

The anti-drip filling technology of the high precision liquid filling machine is another important innovation. After the filling is completed, the traditional filling valve is prone to dripping. The dripping liquid not only affects the measurement accuracy of the product, leading to inconsistent actual content of each bottle of product, but also pollutes the machine surface and production environment, increasing cleaning costs. The anti-drip filling of Rich Packing liquid filling machine adopts servo motor micro-reversal and vacuum suction technology. At the moment when filling stops, the residual liquid in the filling tube can be quickly sucked back, effectively preventing liquid dripping. This technology not only ensures the further improvement of feeding precision, ensures that the dosage of each bottle of product is accurately controllable, but also keeps the machine clean at all times, reduces the workload of cleaning and maintenance, and improves production efficiency.

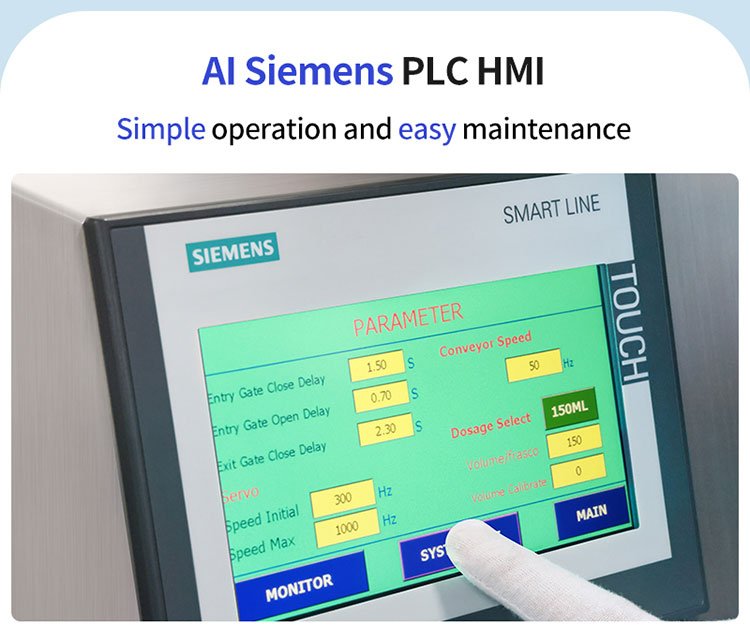

Intelligent Control, Convenient and Efficient

In today's increasingly popular automated production, the convenience of equipment operation and the level of intelligence have become important factors affecting production efficiency. Pharmaceutical liquid filling machine adopts the operation mode of PLC program control + touch screen man-machine interface, realizing intelligent control and bringing enterprises a convenient and efficient production experience.

PLC program control is the core of equipment intelligence. PLC (Programmable Logic Controller) has strong logical operation and control capabilities, and can accurately control various actions of the filling machine according to preset programs, such as the movement of the filling head, the start and stop of the feeding pump, and the adjustment of the filling volume. By writing different programs, the syrup bottling filling machine can adapt to different production processes and parameter requirements, realizing the automation and standardization of the production process. This control method not only greatly reduces the intervention of manual operations, reduces production errors caused by human factors, but also improves the stability and reliability of equipment operation, ensuring the continuous progress of production.

This intelligent control method enables syrup filling machine to quickly adjust parameters when dealing with the production of products of different batches and specifications, realizing flexible production. Whether it is small-batch and multi-variety production or large-batch continuous production, it can maintain an efficient operation state, significantly improving the production efficiency and market response speed of enterprises.

Rich Packing Liquid Filling Machine: An Ideal Choice for Filling in Multiple Industries

To sum up, Rich Packing liquid filling machine, with its strong compatibility, precise filling accuracy, unique anti-loss design, and intelligent and convenient control method, has shown excellent performance and broad application prospects in multiple industries such as pharmaceuticals, health products, food, and chemicals. It can not only meet the various needs of enterprises for liquid filling production, but also help enterprises reduce costs, improve efficiency, and ensure product quality, making it an ideal choice for modern liquid filling production.

IPv6 network supported

IPv6 network supported