Pharmaceutical Blister Pack Machine

Technical parameter

|

Model |

DPP-270Max |

|

Production Capacity |

11,200 packs/hour |

|

Max. Shaping Dia. And Depth |

250*160*15mmMax. Depth26mm(custom-made) |

|

Blanking |

20~180blisters/min (aluminum plastic) 20~120 blisters/min (aluminum aluminum) |

|

Power of Main Motor |

1.5kW |

|

Total Power |

6.0kW |

|

Power supply |

380V/220V/50Hz |

|

Standard Travel Range |

40~160mm |

|

Standard Plate |

80*57mm |

|

Thickness and Width of PVC |

260×0.15~0.45mm |

|

Thickness and Width of PTP |

260×0.02~0.03mm |

|

Dialyzing Paper |

50~100g*260mm |

|

Vacuum |

0.4MPa-0.6MPa |

|

gas consumption |

≥0.2m3/min |

|

Noise |

<75dBA |

|

Mold Cooling |

Runing water or circulating water It is recommended to use constant temperature cold water 60L/H |

|

Weight |

Net weight 2600kg |

|

Overall Size of Machine |

3500×740×1680 mm(L*W*H) |

***Configuration List.

|

Name |

Spec./Model |

Qty |

Manufacturer |

|

Servo Motor |

ECMA-C20807RS |

1 |

Taiwan taida |

|

server Driver |

server Driver |

1 |

Taiwan taida |

|

PLC main module |

CP1L-M30DR-A |

1 |

Omron |

|

PLC temperature module |

CP1W-TSOO2 |

1 |

Omron |

|

PLC touch screen |

6AV6/648-0BC11-3AX0 |

1 |

Siemens |

|

Encoder |

ZSP3806-003G-1500BZ3-5-24F |

1 |

United States Rip Ann Waco |

|

Main motor |

RC series helical gear motor |

1 |

Suncheon |

|

Frequency converter |

VFD015B43A |

|

taiwantaida |

|

Stainless steel plate |

304 316 |

|

Korea,japan |

|

Switching power supply |

NES-100-24 |

|

Taiwan mingwei |

|

Positioning cylinder |

SDA32×10 |

|

AirTAC |

|

Double pressure reducing valve |

BFC4000-N |

|

AirTAC |

|

The electromagnetic valve |

4V210-08 |

|

AirTAC |

|

Pressure reducing valve |

AC2010-02 |

|

AirTAC |

|

emergency button |

XB2-BS542 |

|

Schneider |

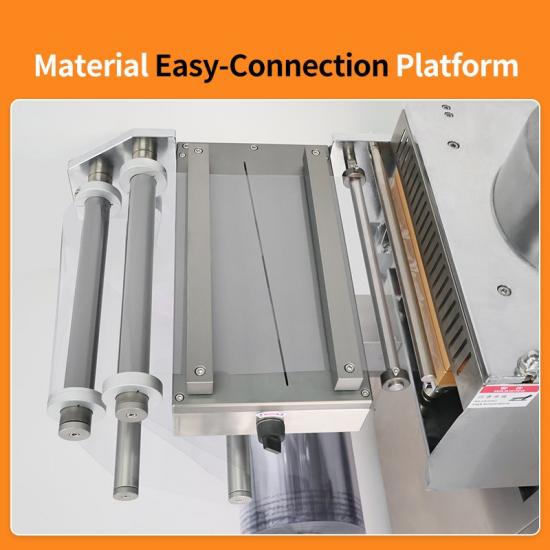

Blister packer machine 270Max uses a new type of servo motor roller press shaft traction, there are various features in 270Max, including 0 error traction accuracy, fast speed, no retreat in packaging material when 270Max stops. Utilizing a large platform design, the 270Max blister packaging machine is very good in the design. Built-in under the body, both the power transmission and cam box makes the blistering machine convenient to clean and maintain after using it.

Using blister packer machine with the function of PVC and the PTP fragments stop and automatic alarm, the waste can be dramatically reduced, the efficiency of raw material utilization can be dramatically improved, it is a quite convenient for people to use.

270Max blister pack machine uses the mould modular design, pull-out card slot rapid-connect installation, the straightforward and rapid to adjust the mould, sets of mould can be quickly installed within 18 minutes.

Using blister packing machine of the cam box mandrel can fix forming, heat-sealing and cutting stations, the horizontal positioning reference is unified, adjustment scale is unified, it is very convenient to change the alignment for people.

Equipped with for people safety covers, including forming heat-sealing and for people punching stations, it is very safe for people to operate the blister pack machine, safely protect people who use it.

Blister packing machine, high in accuracy, very excellent in integration, simple in operation, all the data programmed, frequency conversion speed control and so on.

Blister Packing Machine: 7 Expert Selection Tips for Pharmaceutical & Nutraceutical Manufacturers

For pharmaceutical and nutraceutical manufacturers, choosing the right Blister Packing Machine is a decision that impacts compliance, production efficiency, and product shelf life. A mismatched machine can lead to FDA/EMA audit failures, 10-15% product waste, or missed delivery deadlines. As a 32-year leader in pharmaceutical packaging machinery, Rich Packing has helped 4,320+ global clients select blister packaging machine solutions tailored to their needs. This guide takes a scientific, data-driven approach to break down the key factors for selection, ensuring you invest in a machine that aligns with your dosage (tablets, capsules), capacity, and regulatory requirements.

Unlike generic guides that list parameters without context, this article integrates material science, compliance standards, and real-world production scenarios. We'll also highlight how Rich Packing's automatic blister packing machine lineup (Alu-PVC, Alu-Alu, Paper-PVC, Blister Card) addresses the unique pain points of pharmaceutical and nutraceutical production.

1. Start with Compliance: Match the Blister Packing Machine to Global Regulatory Standards

Compliance is non-negotiable for pharmaceutical/nutraceutical production—and your Blister Packing Machine is the first line of defense against audit risks. Different markets have strict requirements for blister packaging, and your machine must be engineered to meet them:

Key Regulatory Requirements to Verify

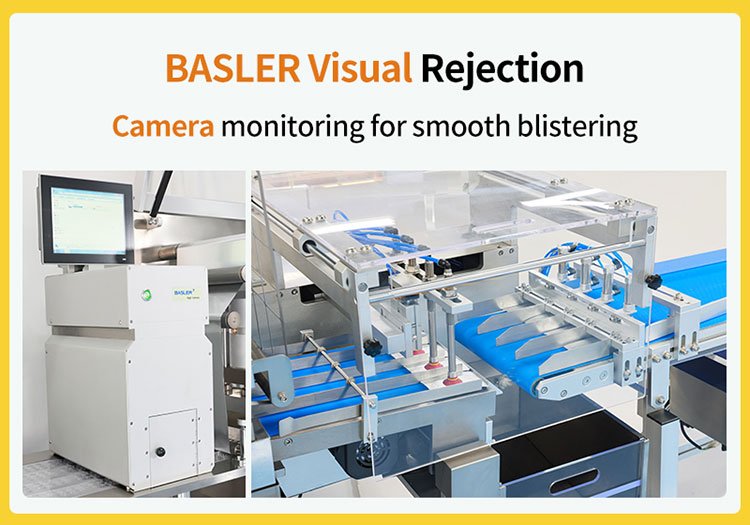

• FDA 21 CFR Part 11: The machine must support data traceability (batch numbers, production time, temperature settings) and electronic record-keeping. Rich Packing's pharmaceutical blister packing machine models come with built-in PLC systems that auto-log all production data, exportable to PDF/Excel for audits.

• EU GMP Annex 1: Requires machine surfaces to be non-reactive, non-toxic, and easy to clean. All product-contacting parts of our blister machines are made of 316L stainless steel (Ra ≤0.8μm surface roughness), preventing cross-contamination.

• Material Compatibility: For Alu-Alu blister packs (used for oxygen-sensitive drugs like vitamins), the machine must achieve a heat-seal strength of ≥1.5 N/15mm (ASTM F88 standard) to meet EU EN 868-5 and US USP <1207> requirements.

2. Choose by Dosage Form: Tablet vs. Capsule Blister Packing Machine Requirements

Tablets and capsules have distinct physical properties (hardness, shape, fragility) that demand different blister machine designs. A one-size-fits-all machine will lead to product damage or inefficient packaging:

Tablet Blister Packing Machine Essentials

• Tablet Hardness Adaptation: For brittle tablets (hardness <4 kgf), the machine needs a gentle feeding system (vibratory conveyor with adjustable frequency) to avoid chipping. Rich Packing's tablet blister packing machine uses special tablet feeder that reduce breakage rates to <0.5%.

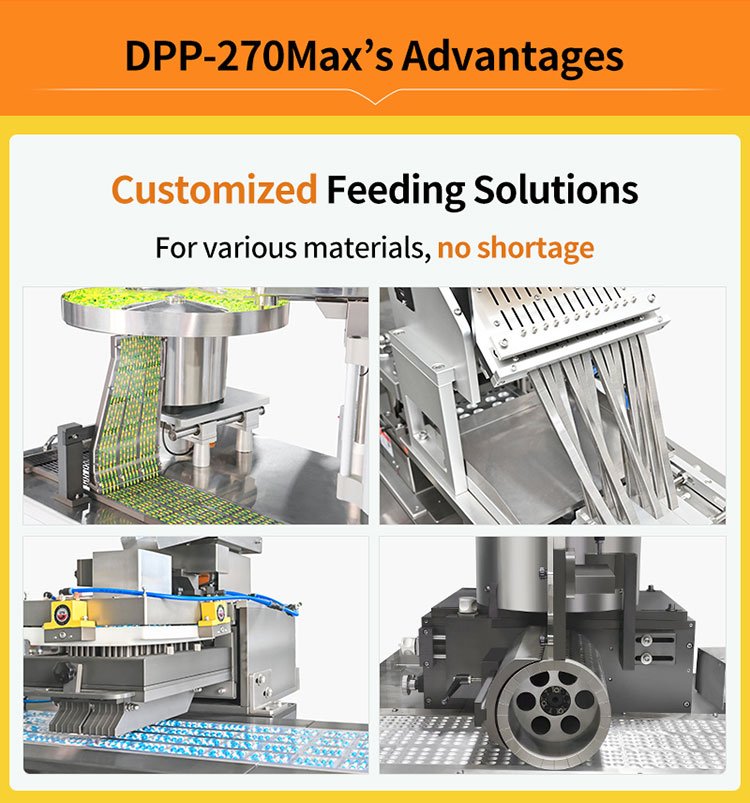

• Shape Compatibility: Oval, triangular, or scored tablets require a customized, fully automated feeding system. Our machines can provide a stable and rapid tablet supply without any shortages.

Capsule Blister Packing Machine Essentials

• Capsule Integrity Protection: Gelatin or plant-based capsules (e.g., HPMC) are prone to deformation under heat. The machine's forming temperature must be precisely controlled (100-120°C for PVC, 130-150°C for PP) to avoid capsule softening.

• Orientation Alignment: Our capsule feeding system ensures consistent capsule cap orientation without damaging the capsules; it is fast and efficient, ensuring a blister pack machine capacity of 10,000 pieces per hour.

Pro Tip

If you produce both tablets and capsules, prioritize a Blister Packing Machine with modular feeding systems—like Rich Packing's DPP series, which allows switching between tablet and capsule feeding modules in 10 minutes.

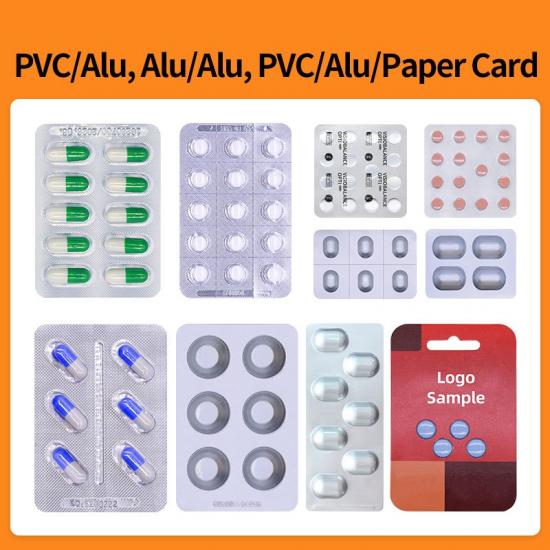

4. Blister Material Compatibility: Alu-PVC, Alu-Alu, or Paper-PVC?

The Blister Packing Machine must be engineered to work with your chosen packaging material—each has unique thermal and mechanical properties that impact machine performance:

Material Science Breakdown

• Alu-PVC: Most common for tablets/capsules (oxygen ≤5 cm³/m²·day·atm). Requires a machine with precise temperature control (100-110°C) and pressure (0.3-0.5 MPa) to avoid PVC degradation.

• Alu-Alu: Used for light/oxygen-sensitive products (e.g., melatonin, probiotics). Oxygen ≤0.1 cm³/m²·day·atm. Demands a dual-seal system (first seal: 130°C, second seal: 140°C) to ensure hermeticity—Rich Packing's DPP blister packing machine uses servo-driven heat-seal heads for uniform temperature distribution.

• Paper-PVC: Sustainable alternative for eco-conscious brands. Requires a machine with low forming temperature (90-100°C) to prevent paper charring. Our machines include a moisture control module to handle paper's hygroscopic nature.

5. Key Technical Parameters That Impact Long-Term Performance

Don't get distracted by marketing jargon—focus on these 3 science-backed parameters to evaluate Blister Packing Machine quality:

Forming Accuracy (±0.1mm Tolerance)

Blisters with uneven walls (thickness variation >0.2mm) are prone to tearing during transportation. Rich Packing's machines use CNC-machined forming molds and laser positioning to ensure blister depth/width consistency—critical for compliance with EU EN 868-4.

Heat-Seal Uniformity

A 5°C temperature variation across the seal area causes 10-15% of blisters to fail leak tests. Our Blister Packing Machine features PID temperature control (precision ±1°C) and silicone seal pads with uniform hardness (Shore A 70-75) to eliminate hot spots.

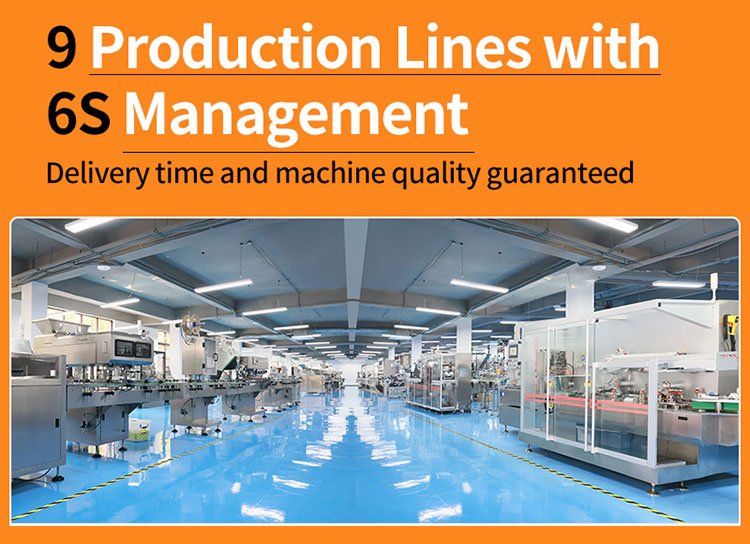

6. Supplier Reliability: Prioritize Service & Support (Not Just Price)

A Blister Packing Machine is a 10-year investment—your supplier's post-purchase support directly impacts uptime. Rich Packing's service package stands out for 4 key reasons:

• Global On-Site Service: Engineers available in EU (Munich), US (New York), and SEA (Jakarta) to provide installation, commissioning, and training within 36 hours.

• 3-Year Component Warranty: Double the industry average (1.5 years) for critical parts like servo motors and PLC systems.

• Free Wearing Parts (1 Year): Includes seal pads, forming molds, and feeding belts.

• DDP/DDU Shipping: We handle customs clearance and logistics, ensuring the machine arrives pre-calibrated and ready to run.

7. Avoid These 3 Common Selection Mistakes

Even experienced manufacturers make these errors—here's how to steer clear:

Mistake 1: Overlooking Line Integration

A Blister Packing Machine that can't connect to your existing counting machine or cartoning machine creates bottlenecks. Rich Packing's machines support MES system integration and come with standard interfaces (EtherNet/IP) to link with other equipment in your production line.

Mistake 2: Ignoring Future Scalability

Your business will grow—choose a machine that supports module upgrades. Our DPP series can add features like online leak testing, batch coding, or blister card packaging without replacing the entire unit.

Mistake 3: Compromising on Cleanability

GMP requires machines to be cleaned in ≤30 minutes. Rich Packing's pharmaceutical blister packing machine has a modular design with tool-free disassembly—all product-contacting parts can be removed and sanitized without specialized tools.

Conclusion: Invest in a Blister Packing Machine That Grows with Your Business

The right Blister Packing Machine isn't just a piece of equipment—it's a partner in compliance and efficiency. By focusing on regulatory alignment,剂型 compatibility, technical precision, and supplier support, you'll avoid costly mistakes and unlock long-term value.

Rich Packing's blister packing lineup includes Alu-PVC, Alu-Alu, Paper-PVC, and Blister Card models—all backed by global service and a 3-year warranty. Whether you're a small nutraceutical startup or a large pharmaceutical CMO, we'll tailor a solution to your needs.

To request a custom quote or free sample run with your product, visit our official site or contact our technical team.

IPv6 network supported

IPv6 network supported