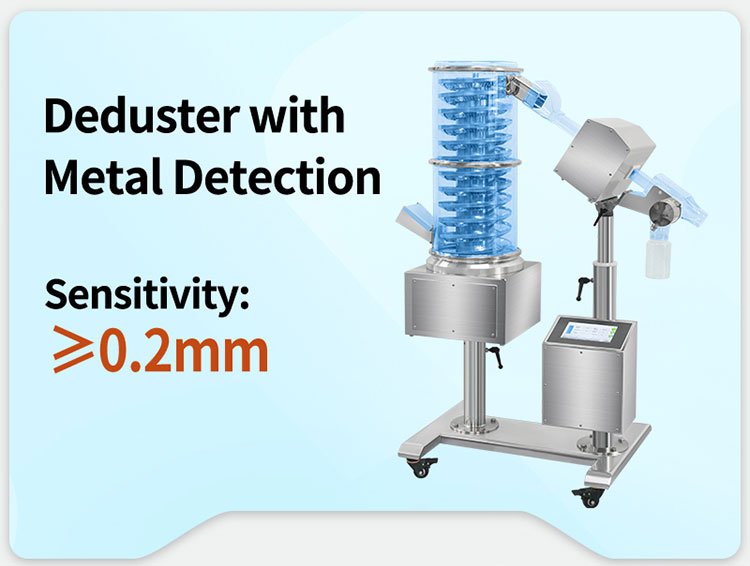

Deduster with Metal Detection

| Product Name | Automatic Deduster with Metal Detector |

| Precision | Fe <0.2mm, Non-Fe <0.3mm, SUS <0.4mm |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Capsule tablet deduster with metal detection: Intelligently ensuring drug production safety and quality

How integrated design improves efficiency and compliance for pharmaceutical companies

In modern pharmaceutical production, every pill is directly related to patient health. As a key piece of equipment on the pharmaceutical production line, the capsule tablet deduster with metal detector integrates two functions: capsule tablet deduster with metal detection cleaning and metal detection. This not only significantly improves production efficiency but also provides a double guarantee for drug safety.

What is a tablet deduster with metal detection?

The automatic tablet deduster with metal detection is a highly integrated pharmaceutical inspection device that combines traditional (dust removal, polishing, and deburring ) and metal detection (metal inspection) processes into a single device. This design overcomes the pain points of two separate devices, which previously required large space, multiple material transfer steps, and low pharmaceutical packaging production efficiency. It achieves a seamless transition from tablet and capsule cleaning to metal foreign body detection and removal.

Working principle and core functions of capsule tablet deduster with metal detection

Intelligent workflow

The tablet deduster machine with metal detecting has a clear and efficient workflow: tablets first enter the deduster with metal detection mechanism through the feed inlet. Driven by the spiral vibrating screen and exciter, the tablets continuously vibrate and rise. This process effectively removes loose powder, burrs, and flash from their surfaces, resulting in a polished finish. The resulting dust is collected by suction and discharge lines and transported to a powder recovery device for reuse.

The cleaned tablets then pass through a feeding tube and into a tablet capsule polisher with metal detection. Three detection coils (first, second, and third) within the detector chamber work based on the principle of electromagnetic induction, accurately identifying any metal impurities, including ferrous, non-ferrous metals, and stainless steel, that may be present in the tablets.

Once metal contaminants are detected, the control system immediately activates the rejection mechanism. The rotating electromagnet drives the rejection flap to rotate rapidly, accurately separating unqualified products containing metal impurities, ensuring that only qualified products enter the next process.

Powder recovery and environmental value

It is worth mentioning that the pharmaceutical powder generated during the screening process is effectively collected and can be recycled and reused, which not only reduces material waste but also meets the environmental protection requirements of the modern pharmaceutical industry and the strict requirements of the United States, Europe and other places, meeting ccGMP, CE, RoHS and other standards, while tablet deduster automatic also reducing production costs.

Outstanding advantages of capsule tablet deduster with metal detection

Highly integrated functions

integration of multiple functions such as screening, metal detection, rejection and even loading significantly reduces the equipment footprint and material transfer links, and improves overall production efficiency.

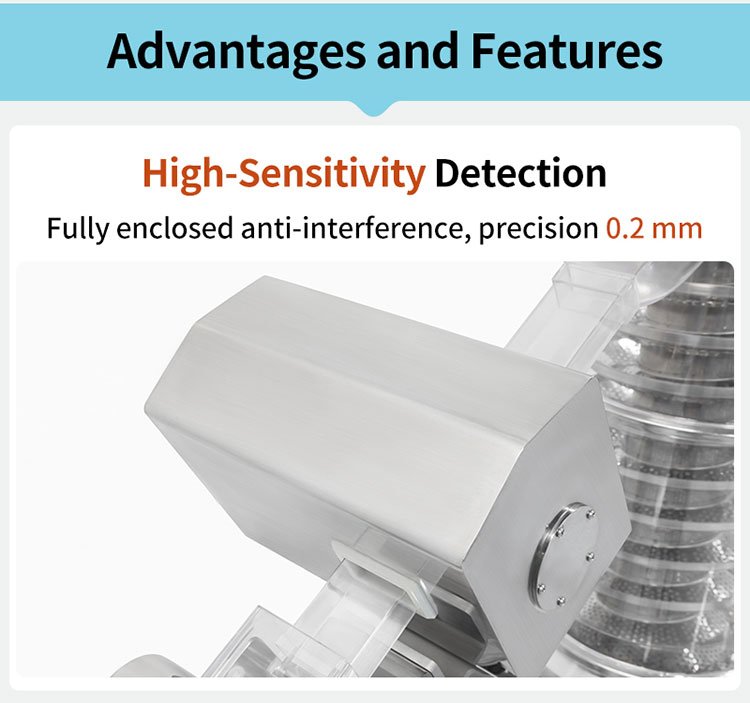

Ensure detection accuracy

Excellent design (such as the separation of the screen mechanism and the metal detection mechanism) can effectively reduce the interference of vibration generated by the screen on precision metal detection, ensure the accuracy and reliability of metal detection, and achieve a high precision of 0.2mm sensitivity, which is difficult to achieve with separate equipment.

Comply with strict regulations

High speed tablet deduster with metal detection metal inspection equipment is usually made of stainless steel 304, and the parts that come into contact with the material are made of stainless steel 316L. It is mirror-finished and easy to clean and disinfect, meeting the strict hygiene standards and requirements of the pharmaceutical industry such as ccGMP.

Easy to operate and flexible

The automatic tablet deduster with metal inspection is equipped with universal wheels and a push rod, making it easy to move between different production lines. The screen body supports height, length, and universal rotation , making it easy to connect to tablet press machines or fully or semi-automatic capsule filling machines in different directions, demonstrating excellent adaptability to production lines.

Choosing the right machine for capsule and tablet production

Although the capsule tablet deduster with metal detection is suitable for both capsules and tablets, there are differences in their production characteristics. Therefore, the following points need to be considered when selecting:

Product feature considerations

Capsules are generally more fragile than tablets. Therefore, when selecting a capsule polishing machine with metal detection for tablet screening, prioritize features that minimize breakage. For example, gentle vibration or specialized internal structures can minimize the risk of breakage during the cleaning process. Some high-quality equipment can achieve a breakage rate of 1.2% or less for brittle capsules.

Tablet production is more concerned with surface cleanliness and smoothness. A detailed understanding of the automatic capsule polishing machine and metal detector's screen mechanism design (such as a spiral vibrating screen) is required to examine its ability to remove dust and burrs.

Production capacity matching

Depending on your actual capsule and tablet production needs, you'll need to select a screening capsule tablet deduster with metal detection that matches your production volume . For example, the RQ-DMM model can handle up to 500,000 pieces per hour, making it ideal for large-scale pharmaceutical and nutraceutical production lines.

Compliance requirements

For the pharmaceutical industry, it is crucial that the materials, design, and validation documentation used in pharmaceutical tablet detectors comply with relevant regulations, such as cGMP and CE . Ensure that all metal parts of the tablet capsule polishing machine that come into contact with tablets are made of 316L stainless steel with a mirror finish, meeting cGMP requirements.

Equipment stability and accuracy

Understand the high precision capsule tablet metal detector's detection accuracy (not just its empty machine sensitivity) and anti-interference capabilities under actual material operation conditions. The design that separates the working area from the mechanical area helps improve detection stability.

Intelligence and after-sales service

As the pharmaceutical industry's demand for intelligence and digitalization increases, screening capsule tablet deduster with metal detection are also evolving. In the future, we may see more intelligent devices integrating AI visual inspection, enabling predictive maintenance, and deeper integration into the Industrial Internet of Things (IIoT). At the same time, reliable technical support and responsive maintenance services are crucial to ensuring continuous and stable production line operations.

Conclusion

Through its highly integrated design and intelligent control, the pharmaceutical capsule tablet deduster with metal detection significantly improves efficiency, quality control, and resource utilization in tablet and capsule production . It is an indispensable piece of equipment in modern pharmaceutical production. Choosing the right equipment not only meets production needs but also represents a solemn commitment to drug quality and patient safety.

We hope this article provides a comprehensive understanding of capsule tablet deduster with metal detection and the key points to consider when selecting one. If you have further questions or need details on a specific model, please feel free to contact us.

IPv6 network supported

IPv6 network supported