Mini Lab Automatic Capsule Filler Capsule Filling Machine

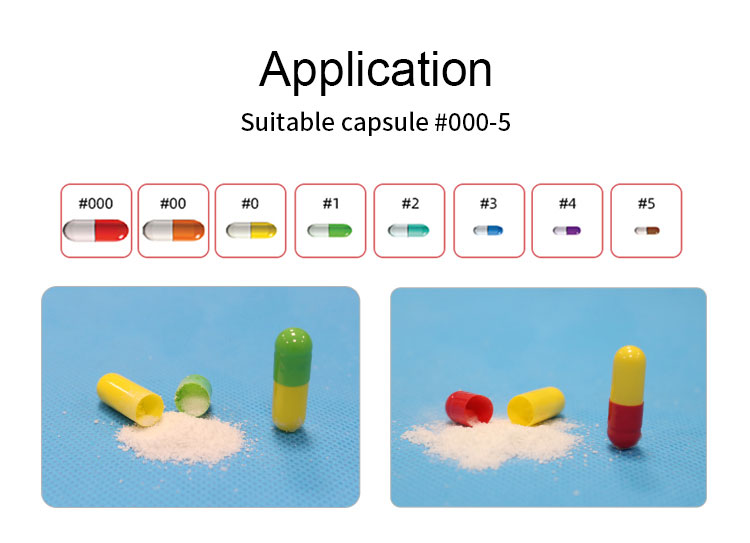

This mini capsule filler machine NJP-400C is the mini machine suitableto mini scales laboratories that fills granules powder into capsules. Thecapacity efficiency of NJP400C is 24000 capsules filling in the one hour. NJP400C is good for capsules size 000,00,0,1,2,3,4,5#. Ourrich packing model NJP400C is mostly used in university school laboratories and small mini pharmacies. *** Applications

*** NJP400C is small in size and fully functional, NJP400C has a small footprint but has all the functions of large capsule filling.

*** NJP400C complete turntable sealing grade, NJP400C uses high-grade seal ring settings where the turntable is linked to the rotating shaft.

*** NJP400C strong rejection function, NJP400C automatically rejects unqualified finished capsules during operation.

*** Why choose ours NJP-400 C model? This extremely cost-effective mini capsule filling machine NJP400 is very suitable for pharmaceutical laboratories and colleges and universities' pharmaceutical professional courses. The volume of NJP400C is the same as that of NJP200C, the function is also the same, and the applicability is also the same. However, we reset the workbench of each capsule filling machine, which doubled the production speed of NJP400C.

Under the premise of ensuring the speed of production, with the help of our company's professional engineers, the stability of NJP400C in long-term operation has also been greatly improved. Because we have adopted a patent application scheme on the turntable of the capsule filling machine, which utilizes the principle that each contact point under the worktable is uniformly stressed.

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

*** Technical parameter

| Name | NJP-400C small capsule filling machine,capsules filling machine small scale |

|

Production capacity |

24000 pcs /h |

|

Net weight of machine |

300 Kg |

|

Overall size of machine |

700×580×1650(mm) |

|

Power |

380/220 V 50 Hz |

|

Total power |

3.2 KW |

NJP Automatic Capsule Filler Machine: 6 Unbeatable Advantages of Small Models for Lab and Small-Batch Production

If you're a lab manager at a pharmaceutical R&D center, a startup nutraceutical brand, or a contract manufacturer handling small-batch orders, you've probably struggled with mismatched equipment: manual capsule fillers are too slow for even tiny production runs, while large automatic machines waste space and money on 10,000-capule batches. The solution? NJP-400C Small NJP Automatic Capsule Filling Machine models - specifically engineered for experimental and small-scale production by Rich Packing (https://www.richpacking020.com/), a 33-year leader in pharmaceutical machinery. These aren't "watered-down" versions of big machines; they're built from the ground up to solve the unique pain points of small-batch work-like frequent formula changes, tight lab spaces, and strict cleaning requirements. Below is a practical, buyer-focused guide to why they're the smart choice, plus how to pick the right one for your needs.

1. Introduction of Small NJP Automatic Capsule Filler Machine?

Before diving into advantages, let's clarify what makes these machines "small"-and why they're different from generic small capsule filling machine options. A small automatic capsule filling machine (like Rich Packing's NJP-200C or NJP-400C) is designed for:

- Capacity: 8000–20,000 capsules per hour (perfect for lab trials, pilot runs, or small-batch production of 55,000–100,000 capsules/day).

- Size: Compact footprint (as small as 990×720×1,890mm)-fits in small workshop corners, unlike large automatic models that need dedicated floor space.

Core Use Cases:

- Experimental production: Testing new drug formulas, optimizing powder flow, or validating capsule size for clinical trials.

- Small-batch production: Making niche products (e.g., personalized vitamins, rare disease medications) or fulfilling low-volume orders without wasting resources.

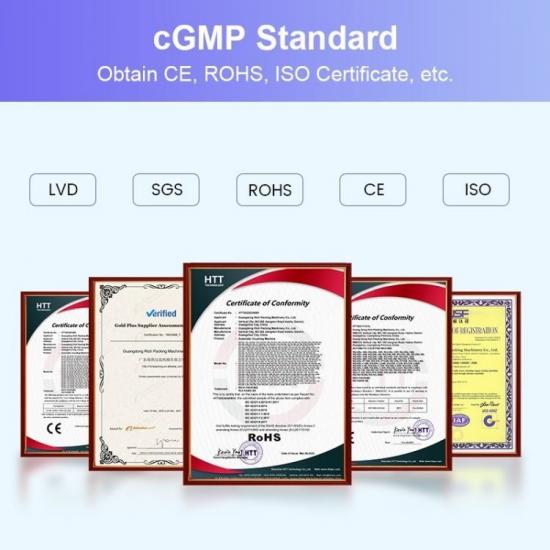

Crucially, these are still automatic capsule filling machine models-no manual feeding or dosing-so they avoid the human error that plagues manual or semi-auto alternatives. And as part of the NJP series, they carry the same CE, FDA, and cGMP compliance as Rich Packing's larger machines-critical for meeting global regulatory standards.

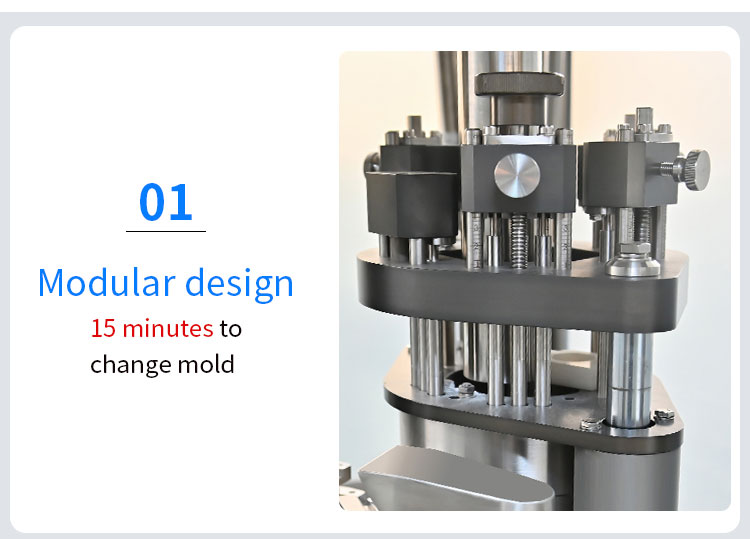

2. Advantage 1: Modular Design in NJP 400C Automatic Capsule Filler

The biggest headache in lab or small-batch work is switching between products (e.g., testing a painkiller powder in the morning, a probiotic blend in the afternoon). Generic small scale capsule filling machine options force you to disassemble the entire unit for changes, taking 1–2 hours of downtime. Small NJP Automatic Capsule Filler Machine models fix this with modular components:

- Key Modules: The machine splits into 2 core parts-filling module (controls dose), feeding module (supplies empty capsules), and cleaning module (collects dust). Each module clicks in/out without screws or special tools.

- Fast Changeovers: Swap a filling module for a different capsule size (from 000 to 5) in 15 minutes flat. For lab teams running 3+ trials a day, this cuts downtime by 75% compared to non-modular machines.

One US nutraceutical startup told us: "We used to spend 2 hours switching formulas with our old machine. Now with the mini NJP capsule machine model, we do it in 10 minutes-we've doubled the number of product tests we run weekly."

3. Advantage 2: Easy Cleaning of NJP Capsule Machine-Meet cGMP Standards Without the Hassle

Lab and small-batch production face strict cleaning requirements: cross-contamination between formulas (e.g., a steroid powder leaving residue in a vitamin batch) can invalidate trials or trigger FDA fines. NJP Capsule Filler Machine models are built for low-effort, compliant cleaning:

- Hygienic Materials: All product-contacting parts are made of 316L stainless steel-smooth, non-porous, and resistant to harsh cleaning agents (e.g., ethanol, hydrogen peroxide). No hidden crevices where powder can hide.

- Simplified Disassembly: Modular design means you can remove the filling module and soak it in a cleaning bath-no need to wipe down the entire machine.

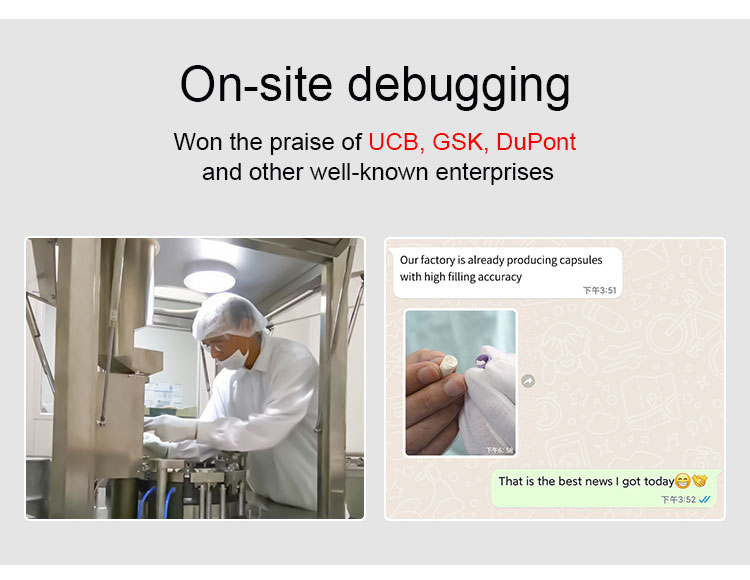

- Validation-Friendly: Rich Packing provides a step-by-step cleaning SOP (with photos and timelines) that's pre-approved for cGMP audits. A UK lab used this SOP to pass an MHRA inspection with zero cleaning-related findings.

Compare this to other mini capsule filling machine options: many have glued-on parts or hard-to-reach areas that require 45+ minutes of scrubbing-and still risk cross-contamination.

4. Advantage 3: Easy Maintenance Capsule Filler-Minimize Downtime

Small labs and startups rarely have dedicated maintenance teams-so a broken machine can shut down production for weeks. NJP Mini Capsule Filling Machine models are designed for self-service maintenance:

- Simple Troubleshooting: The 7-inch touchscreen displays clear error codes (e.g., "Feeding Module Jam-Check Capsule Hopper") with fix-it steps in plain English (or 8 other languages). No need to call a technician for minor issues.

- Free one-year supply of consumable parts: Rich Packing includes consumable parts with the complete machine shipment, providing a full year's worth of normally usable spare parts, saving you significant costs. You can also order through Rich Packing's US/EU warehouses and receive your order within 2-3 days. Replacing refill modules costs 50% less than parts for non-NJP machines.

- 3-Year Warranty: Rich Packing includes a 3-year warranty (double the industry average for small capsule fillers) that covers labor and parts. A French clinical research lab recently had a feeding module replaced for free-no paperwork delays.

One American startup founder summarized: “We didn’t have engineers. With our NJP 400 machine, we solved the blockage ourselves using the complete technical white paper provided by Rich Packing—and production was back on track within 30 minutes.”

5. Why NJP 400C Excel in Experimental Production or Small-Batch Production (3 Key Benefits)

For lab teams running pilot production, NJP 400C Capsule Filling Machine models offer advantages no generic lab capsule filling machine can match:

Benefit 1: Cost-Effective for Low Volumes

Large automatic machines cost $50k+ and use more energy (2-3kW/h) than needed for small batches. The automatic small capsule filling machine model costs 60% less upfront and uses just 0.5kW/h-perfect for startups with tight budgets. A US herbal supplement brand saved $30k upfront and $1,200/year on electricity compared to a large machine.

Benefit 2: Space-Saving for Small Facilities

Many small-batch producers work in 500-1,000 sq. ft. workshops. The automatic pill capsule filling machine model fits on a standard lab bench-no need to rearrange your space or rent extra square footage. A Spanish contract manufacturer added two small NJP machines to their existing workshop without expanding.

Benefit 3: Data Logging for Audits

Capsule filling production need detailed records (e.g., "Batch 123: 2,000 capsules filled at 8:30 AM, average weight 250mg"). The small NJP machine logs every run automatically-export data to Excel or PDF with one click. No more manual record-keeping errors.

Why NJP Automatic Capsule Filling Machine Is Your Better Choice

For lab teams and small-batch producers, generic capsule filling machine small options force you to choose between precision, speed, and compliance. Small NJP Automatic Capsule Filler Machine models from Rich Packing check all three boxes-modular for fast changes, easy to clean/maintain, and built for the unique needs of experimental and small-scale work. Plus, with 33 years of pharmaceutical machinery expertise, Rich Packing delivers the reliability small teams can't afford to live without.

To get a custom quote, visit Rich Packing's official site (https://www.richpacking020.com/) or contact global support team via WhatsApp (+8618023458944).

IPv6 network supported

IPv6 network supported