NJP 3800D Capsule Encapsulation Filling Machine

The NJP-3800D capsule filling machine medical is specifically engineered for efficiency and convenience. Its modular design allows for quick replacement of all molds in just 15 minutes, facilitating easy maintenance and cleaning. This feature ensures minimal downtime and optimal operational efficiency, saving time and resources for pharmaceutical manufacturers.

One of the key features of the NJP-3800D is its versatility. It can handle a wide range of capsule sizes and formulations, making it suitable for various pharmaceutical production needs. The machine's precision and accuracy ensure uniform filling and dosage consistency, meeting the highest quality standards required in the pharmaceutical industry.

Maintenance and cleaning of the NJP-3800D capsule encapsulation filling machine are streamlined for convenience. The machine is designed for easy access to critical components, facilitating routine maintenance tasks and ensuring optimal performance over time. With simplified maintenance procedures, operators can focus on maximizing production efficiency and minimizing disruptions.

Moreover, the NJP-3800D is designed with user-friendliness in mind. It features an intuitive interface that allows operators to easily monitor and control the filling process. This user-friendly design reduces the learning curve for operators, ensuring smooth and efficient operation.

In conclusion, the NJP-3800D automatic control capsule filling machine sets a new standard for high-volume capsule filling. Its innovative features, such as the BEKER vacuum pump, vacuum powder feeding machine, and modular design, make it an ideal choice for pharmaceutical manufacturers looking to optimize their production processes. With its high efficiency, precision, and user-friendly design, the NJP-3800D is poised to revolutionize capsule filling operations in the pharmaceutical industry.

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

*** Technical parameter

| Name | high speed capsule filling machine |

|

Production capacity |

228,000 pcs/h |

|

Net weight of machine |

2200Kg |

|

Overall size of machine |

1395×1180×2200 |

|

Power |

380/220V 50Hz |

|

Total power |

10.5KW |

|

Applicable capsule |

00,0,1,2,3,4,5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Powder、granule、pellet、tablet |

NJP-3800D High Speed Capsule Filling Machine: The Most Suitable Capsule Machine for Pharmaceutical and Nutraceutical Capsule Production

If you're a procurement manager or production director at a US pharmaceutical or nutraceutical company, you know how critical choosing the right capsule filling machine is. A subpar machine can lead to costly production delays, compliance issues with the FDA, and inconsistent capsule quality—all of which hurt your brand's reputation and bottom line. That's why we've created this in-depth buying guide focused on the NJP-3800D High Speed Capsule Filling Machine: a solution designed to solve the unique challenges US buyers face when sourcing a capsule filling machine for pharma and nutraceutical production.

1. Start with Your Production Needs: Why NJP-3800D's High Speed Fits US Market Demands

Before investing in any pharmaceutical capsule filling machine, you must first align the machine's capacity with your production goals. US pharma and nutraceutical brands often operate medium to large-scale production lines—whether you're making prescription capsules, vitamin supplements, or herbal remedies—so speed and efficiency are non-negotiable.

The NJP-3800D stands out as a high speed filling capsule machine with a production capacity of up to 3,800 capsules per minute (cpm). Unlike slower manual or semi-automatic models (which typically max out at 500 cpm), this machine eliminates bottlenecks in high-volume production. For example, a US-based nutraceutical brand we worked with recently increased their daily output by 300% after switching from a low-speed filler to the NJP-3800D—cutting their time-to-market for a new multivitamin line by two weeks.

But speed isn't everything: you also need flexibility. The NJP-3800D suitable for capsule sizes from 000 to 5, making it suitable for everything from large-dose pharma capsules to small nutraceutical pellets. This versatility means you won't need to invest in multiple machines if your product lineup expands—a key cost-saving factor for US buyers looking to scale.

2. Compliance Is Non-Negotiable: NJP-3800D Meets US FDA & cGMP Standards

For US buyers, compliance with regulatory standards is make-or-break when choosing a capsule filling machine. The FDA and current Good Manufacturing Practices (cGMP) set strict guidelines for equipment used in pharmaceutical and nutraceutical production—including material safety, hygiene, and traceability.

The NJP-3800D high speed automatic capsule filler is built to exceed these standards:

- Materials: All product-contacting parts are made of 316L stainless steel, a material approved by the FDA for its resistance to corrosion and easy cleaning. This prevents cross-contamination, a top concern for pharma brands.

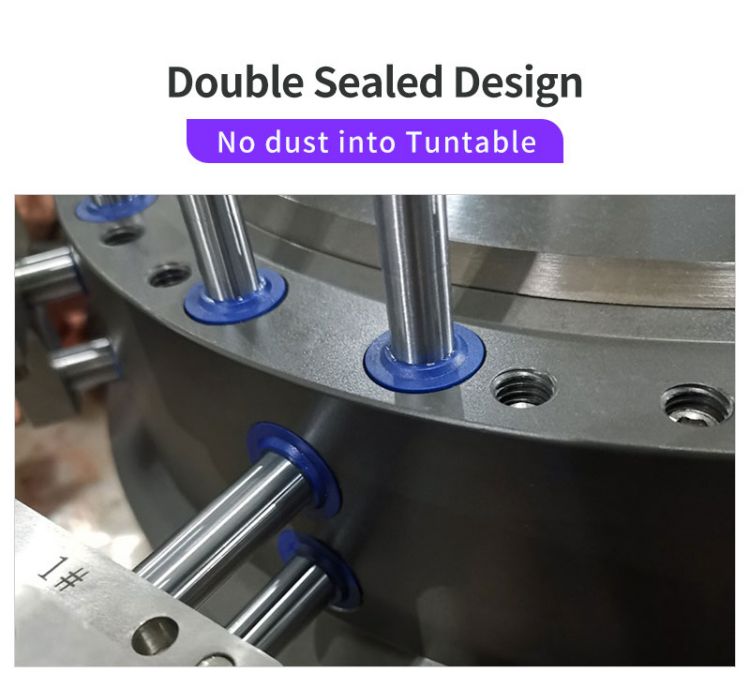

- Hygiene Design: The machine features a fully enclosed filling chamber, dust extraction system, and smooth surfaces with no dead corners—making it easy to sanitize between batches (critical for complying with FDA 21 CFR Part 11).

- Documentation: As a reputable China capsule filling machine manufacturer, Rich Packing provides full compliance documentation for the NJP-3800D, including calibration records, material certificates, and cGMP validation reports. This saves you hours of paperwork when undergoing FDA inspections.

We've had US clients tell us that the NJP-3800D's compliance features helped them pass FDA audits with zero findings—something that's rare with cheaper, non-compliant machines from unvetted manufacturers.

3. Prioritize Automation: Why an Automatic Capsule Filler Saves US Brands Time & Money

Labor costs in the US are among the highest in the world, so investing in an automatic capsule filler like the NJP-3800D is a smart financial decision. Manual or semi-automatic machines require constant operator oversight—leading to higher labor expenses and a greater risk of human error (e.g., incorrect fill weights, capsule damage).

The NJP-3800D's fully automated system includes:

- Auto Capsule Feeding & Orientation: The machine automatically sorts and orients empty capsules, reducing the need for manual handling.

- Precision Fill Control: An advanced servo motor system ensures fill weight accuracy of ±0.5%, eliminating waste from overfilled or underfilled capsules.

- Auto Fault Detection: If the machine detects a jam, low capsule supply, or inconsistent fill weight, it triggers an alarm and pauses production—preventing costly defects.

4. Choose a Trusted Capsule Filling Machine Manufacturer: Why Rich Packing Stands Out for US Buyers

When sourcing a China capsule filling machine, US buyers often worry about manufacturer reliability—Will the company deliver on time? Will they provide after-sales support? Will the machine meet the promised specs?

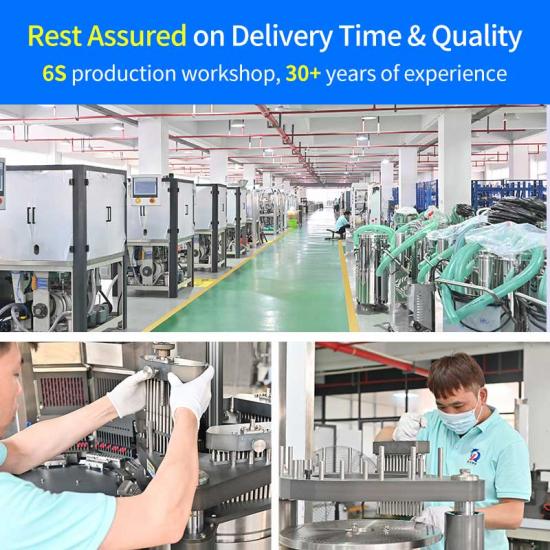

Rich Packing, the manufacturer of the NJP-3800D, addresses these concerns with a track record of serving US clients for over 15 years:

- Proven Expertise: Rich Packing specializes in pharmaceutical and nutraceutical equipment, with a R&D team that updates the NJP-3800D annually to keep up with US regulatory changes (e.g., recent updates to cGMP for nutraceutical).

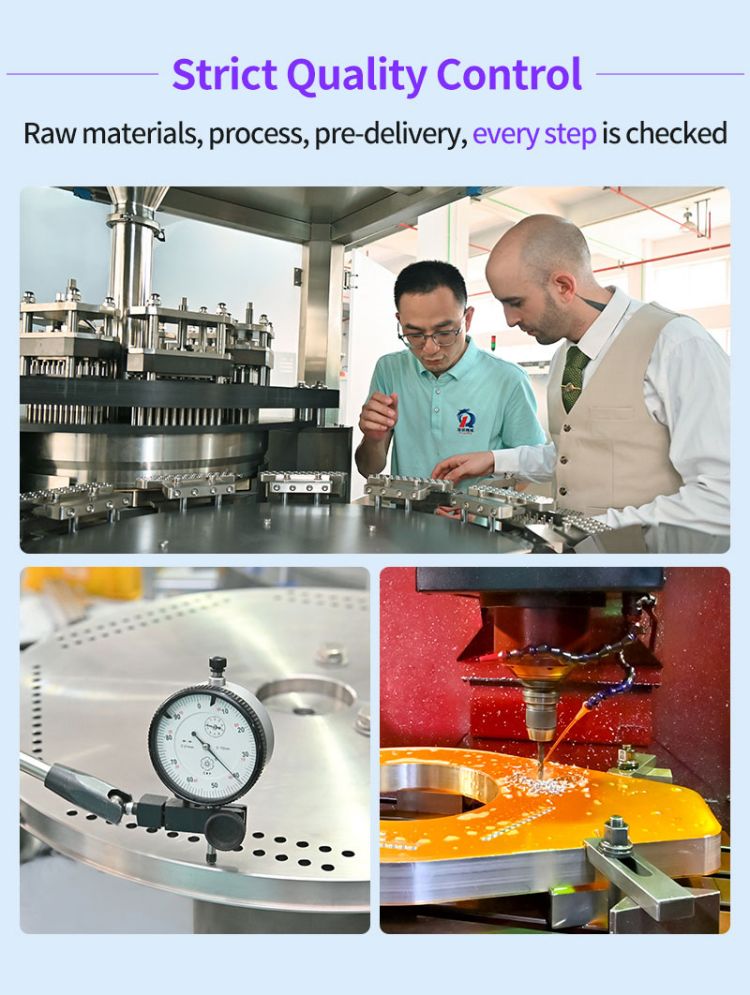

- Quality Control: Every NJP-3800D undergoes a 72-hour factory test before shipment, including running 1 million test capsules to ensure performance. Rich Packing also provides a 2-year warranty—longer than the industry average of 1 year.

- US-Focused Support: The company has a dedicated support team for US clients, available 24/7 via phone or email. They also stock spare parts in a US warehouse, so replacements arrive within 2–3 business days (no waiting for international shipping).

One US nutraceutical brand shared that when their NJP-3800D encapsulation machine needed a replacement part during a busy production run, Rich Packing shipped the part from their US warehouse and had a technician on-site within 48 hours—minimizing downtime to just 6 hours.

5. Test Before You Buy: Request a Sample Run for the NJP-3800D

Even with strong specs and compliance, you should always test a capsule filling machine with your actual product before purchasing. Every pharma and nutraceutical product has unique properties (e.g., powder density, particle size) that can affect machine performance—so a “one-size-fits-all” claim isn't enough.

Rich Packing makes this easy for US buyers:

- Sample Runs: You can send your product (powder, granules, or pellets) to Rich Packing's factory in China, and their team will run a sample production with the NJP-3800D. They'll share video footage of the run, along with a report on fill accuracy, speed, and capsule quality.

- On-Site Demos: For larger orders, Rich Packing can arrange an on-site demo at your US facility. Their technicians will set up the machine, train your team, and run a full production shift—so you can see how it integrates with your existing line.

A US-based herbal supplement company took advantage of the sample run service and discovered that their powder (which is more hygroscopic than average) required a small adjustment to the NJP-3800D's filling chamber. Rich Packing made the modification for free before shipping—ensuring the machine worked perfectly on day one.

6. Plan for Long-Term Use: Evaluate After-Sales Service & Spare Parts

A automatic capsule filling machine is a long-term investment—so US buyers must consider what happens after the machine is installed. Poor after-sales service or slow spare parts delivery can shut down your production line for weeks, costing you thousands in lost revenue.

Rich Packing's after-sales support for the NJP-3800D is tailored to US buyers:

- Training: The company provides free on-site training for your operators and maintenance team, covering everything from setup and operation to troubleshooting and cleaning. They also offer online training modules that your team can access anytime.

- Preventive Maintenance: Rich Packing sends quarterly maintenance reminders and can schedule annual on-site inspections to keep the NJP-3800D running at peak performance. This proactive approach reduces the risk of unexpected breakdowns.

- Spare Parts Guarantee: As mentioned earlier, Rich Packing stocks critical spare parts (e.g., filling pins, capsule separators) in the US. They also offer a 5-year spare parts supply agreement—ensuring you'll have access to parts even as the machine ages.

A US pharmaceutical client told us that the preventive maintenance service helped them reduce the NJP-3800D's downtime to less than 2% per year—well below the industry average of 5%.

7. Compare Costs: Why NJP-3800D Offers the Best Value for US Buyers

Finally, US buyers need to balance quality with cost. While cheaper capsule filling machines may seem appealing, they often lack compliance features, have shorter lifespans, and require more frequent repairs—costing you more in the long run.

The NJP-3800D offers exceptional value by combining:

- Low Total Cost of Ownership (TCO): The machine's high efficiency (3,800 cpm), low maintenance needs, and 2-year warranty mean you'll spend less on labor, repairs, and replacements over its 10+ year lifespan.

- Competitive Pricing: As a direct capsule filling machine manufacturer (no middlemen), Rich Packing offers the NJP-3800D at 15–20% lower prices than US-based manufacturers—without compromising on quality.

IPv6 network supported

IPv6 network supported