NJP-400C Small Automatic Capsule Filling Machine

*** Technical parameter

| Name | Fully automatic 400 capsule filling machine |

|

Production capacity |

24,000 pcs /h |

|

Net weight of machine |

600 Kg |

|

Overall size of machine |

1000×710×1900(mm) |

|

Power |

380/220 V 50 Hz |

|

Total power |

3.5 KW |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

First, let's briefly understand what a capsule filling machine small is. It is a machine whose main function is to accurately fill solid particles, granules, tablets, powders and other drugs into capsule shells and then seal them to provide precise, consistent and convenient packaging for drugs. So what are the characteristics of the NJP-400C small fully automatic capsule filling machine? With a throughput of 400 capsules per minute, it is ideal for laboratory and small-scale production environments.

Why do fully automatic capsule filler has advantages over semi-automatic ones? The fully automatic capsule filling machine provides accurate, fast and efficient operation. Compared with semi-automatic capsule machines, fully automatic capsule machines reduce human errors and improve drug quality. In terms of filling speed, fully automatic equipment far exceeds semi-automatic equipment, which greatly improves production efficiency. In addition, the fully automatic capsule filling machine is simpler and more convenient to use and maintain.

We are an important partner of Fortune 500 companies. They choose us because we rely on more than 30 years of experience in pharmaceutical equipment production and always insist on providing customers with high-quality equipment and thoughtful services. Our equipment and services have been widely recognized and highly praised by customers.

Overall, the NJP-400C small capsule filling machine automatic truly meets the needs of laboratories and small-scale production environments with its high speed, high accuracy and ease of use. NJP-400C is an ideal choice for pharmaceutical companies seeking to improve production efficiency and drug quality.

Small Capsule Filling Machine: 7 Pro Tips for Startups to Choose the Right Automatic Encapsulator

For pharmaceutical, nutraceutical, or supplement startups, selecting the right fully automatic capsule filling machine is a critical decision that directly impacts production efficiency, regulatory compliance, and long-term scalability. Unlike established enterprises with mature workflows and large budgets, startups face unique pain points: limited capital, small-batch production needs, lean teams (no dedicated maintenance engineers), and strict market entry compliance requirements.

This guide, backed by Guangdong Rich Packing Machinery’s 32 years of pharmaceutical machinery expertise, breaks down 7 science-backed selection criteria to help startups avoid costly mistakes—with a focus on why a small capsule filling machine (like the NJP-400C) is often the optimal choice, and how to evaluate it against your business needs.

1. Start with Capsule Filling Capacity: Match to Your Startup’s Current & Future Demand

Startups often overinvest in high-capacity machines (wasting energy and budget) or choose underpowered models (causing production bottlenecks). The scientific way to avoid this is to calculate “current maximum demand + 2-year growth buffer” using this formula:

Daily Production Demand (capsules) = Target Market Size × Expected Market Share × Daily Dosage × 1.2 (growth buffer)

For example: If your startup targets 10,000 daily users (1 capsule/day) with a 5% market share, daily demand = 500 capsules; adding a 20% buffer brings it to 600 capsules/day. A small capsule filling machine like Rich Packing’s NJP-400C (a leading NJP 400 capsule filling machine) is ideal here—it delivers 24,000 capsules/hour, meaning it only needs to run 1.5 hours/day to meet demand, leaving room for growth without idle capacity.

Why Small Capsule Filling Machine Fits Startups

• Space Efficiency: The NJP-400C has a compact footprint (1000×710×1900mm), perfect for startups with limited workshop space.

• Batch Flexibility: It handles batches of 8,000–50,000 capsules—exactly the range most startups need, unlike large machines that require minimum batches of 100,000+.

• Energy Savings: With a total power of 3.5kW, it uses 60% less energy than high-capacity models, cutting monthly utility costs by ![]() 300.

300.

2. Prioritize Compliance: Certifications That Unlock Markets

Regulatory rejection is a death sentence for startups—your small capsule filling machine must hold key certifications to enter global markets. Skip this step, and you’ll face costly rework or delayed launches. Focus on these non-negotiable credentials:

• CE Certification: Mandatory for EU entry, ensuring compliance with Machinery Directive 2006/42/EC (safety and performance). The NJP-400C is CE-certified, eliminating barriers to European markets.

• cGMP Compliance: Global pharmaceutical manufacturing must comply with cGMP standards. The machine's material-contact parts are made of 316L stainless steel (surface roughness Ra ≤0.8μm) and feature a tool-free, modular design, effectively preventing cross-contamination and meeting stringent cGMP hygiene standards.

• ISO 9001: Validates the manufacturer’s quality management system—Rich Packing’s ISO 9001 certification ensures consistent production of the NJP-400C capsule filler.

3. Evaluate Operational Complexity: Choose User-Friendly Models for Lean Teams

Startups rarely have dedicated maintenance engineers—your small capsule filling machine must be easy to operate, clean, and troubleshoot. Look for these user-centric features:

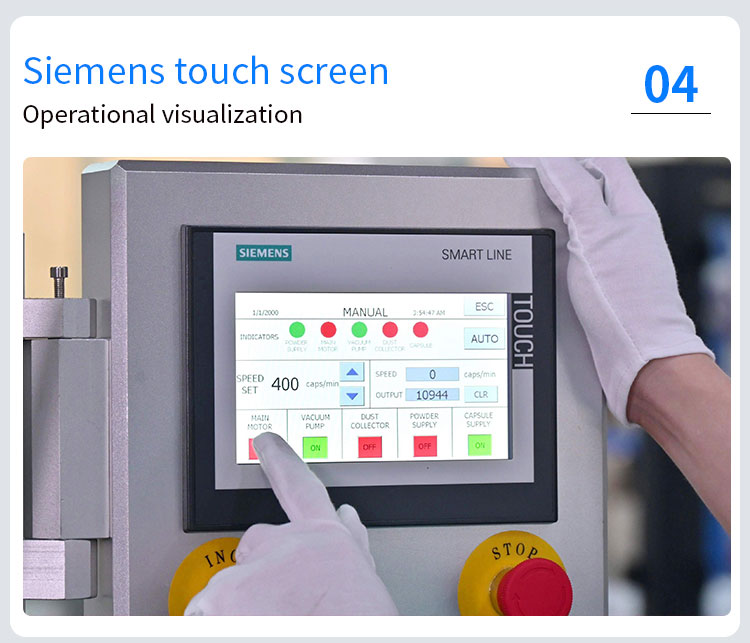

• Intuitive Controls: The NJP-400C’s Siemens touchscreen (multilingual support) displays real-time data (speed, output, errors) and step-by-step guides. New operators master it in 1 day, no specialized training needed.

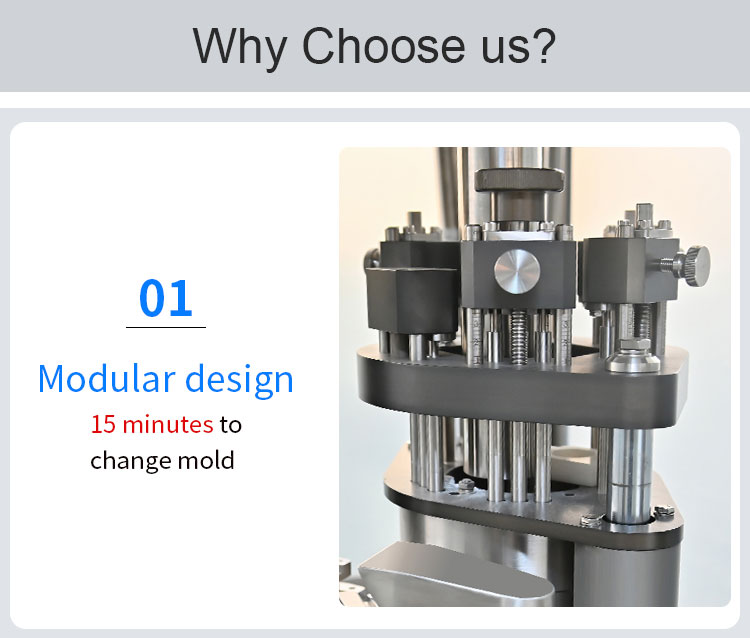

• Tool-Free Maintenance: Modular components (hopper, filling station) can be removed in 15 minutes for cleaning—critical for GMP compliance and reducing downtime.

• Self-Diagnosis: The machine alerts users to common problems (capsule shortage, material shortage) and provides actionable solutions (fault number indication). Users can then find the corresponding solutions in the detailed user manual that comes with the Rich Packing machine, thus minimizing reliance on external support.

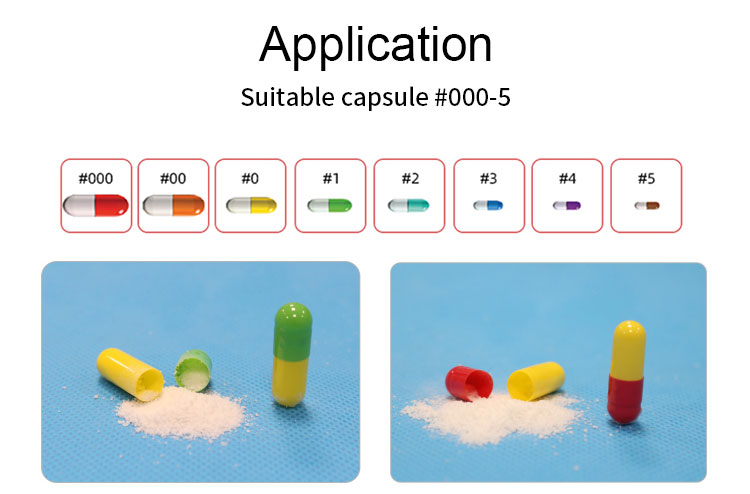

For lab small capsule filling machine needs (e.g., R&D or clinical trials), the NJP-400C’s adjustable filling volume (supports #000–#5 capsules) and precise dosing (±0.5% accuracy) make it a versatile choice for early-stage product development.

4. Calculate Total Cost of Ownership (TCO), Not Just Upfront Price

Startups often fixate on upfront costs, but hidden expenses (maintenance, spare parts, downtime) can double your investment.

How the NJP-400C Reduces TCO

• Upfront Savings: As a small capsule filling machine, it costs 40% less than high-capacity models, aligning with startup budgets.

• Hidden Cost Cuts: Rich Packing offers a 3-year component warranty (triple the industry average) and free 1-year wearing parts (gaskets, seals), saving $2,500+/year.

• Minimal Downtime: Global on-site service (engineers arrive within 72 hours) reduces downtime to <2 hours/year—valued at $600+/hour for startups.

5. Ensure Material Compatibility: Adapt to Your Product Type

Capsule filling machines perform differently with powders, granules, or pellets—choosing the wrong small capsule filling machine leads to product waste or inconsistent quality. The NJP-400C solves this with:

• Pneumatic Feeding: Handles low-fluidity powders (e.g., herbal extracts) without clumping, a common issue with cheap capsule filler machine models.

• Adjustable Filling Volume: It supports tool-free operation, and the height of the six filling rods at the filling station can be adjusted by manually turning the knob to achieve precise dosage adjustment.

6. Prioritize Scalability: Grow Without Replacing Equipment

A small capsule filling machine should grow with your startup—avoid models that become obsolete as you scale. The NJP-400C’s scalability features include:

• Output Upgrades: The NJP400C capsule machine supports full-power operation, from 10,000 capsules/hour for startups to 24,000 capsules/hour.

• Production Line Integration: Seamlessly connects to Rich Packing’s Automatic Counting Machine or Blister Packing Machine and Cartoning Machine, supporting batch expansions from 80,000 to 1800,000 capsules/day.

7. Verify After-Sales Support: A Lifeline for Startups

Poor after-sales support can halt production for weeks—choose a small capsule filling machine manufacturer with global service capabilities. Rich Packing stands out with:

• On-Site Training: Engineers visit your facility to train teams on operation, cleaning, and maintenance (included in purchase).

• Digital Resources: Comprehensive manuals (English/French/Spanish) and video tutorials (e.g., “How to Replace NJP-400C Sealing Rings”) are available 24/7.

• DDP Shipping: Rich Packing handles customs clearance and logistics, ensuring your machine arrives pre-calibrated and ready to run—no hidden import fees.

Conclusion: Choose a Small Capsule Filling Machine That Aligns with Your Startup’s Goals

For startups, the right small capsule filling machine balances capacity, compliance, usability, and cost. The NJP-400C checks all boxes: it’s compact, compliant, user-friendly, and scalable—designed to grow with your business.

IPv6 network supported

IPv6 network supported