Sachet Sorting Machine

| Product Name | Sachet Sorting Counting Machine |

| Capacity | 400 bags/min |

| Voltage | AC380v 3 phases 50Hz, can be Customized on demand |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Sachet Sorting Machine: A Comprehensive Guide for Pharmaceutical Packaging

As the demand for automated packaging solutions surges, the Sachet Sorting Machine has emerged as a cornerstone equipment in modern pharmaceutical production lines. This advanced device is designed to transform chaotic piles of sachets into neatly arranged, orderly stacks, laying a solid foundation for subsequent processes such as cartoning, labeling, and counting. For pharmaceutical manufacturers striving to meet strict regulatory standards and enhance production efficiency, understanding the working mechanism, technical advantages, and application value of the Sachet Sorting Machine is essential. This article will delve into the core knowledge of Sachet Sorter from a scientific and professional perspective, helping you grasp the key information needed for optimizing pharmaceutical packaging processes.

What is a Bag Sorting Counting Machine? Definition and Core Value

A Sachet Sorting Machine, also known as a Pillow Bag Sorting Machine in broader packaging contexts, is a specialized automated equipment designed to sort, arrange, and align irregularly stacked sachets or small bags into a consistent, orderly manner. Unlike manual sorting, which is prone to errors, low efficiency, and contamination risks, it achieves high-precision sorting through mechanical structure and intelligent control systems, ensuring that each sachet enters the next production process (such as cartoning, metal detection, or counting) in a standardized posture.

In the pharmaceutical industry, the core value of the Sachet Collating Machine is particularly prominent. Pharmaceutical sachets (such as powder sachets, oral liquid sachets, and cream sachets) have strict requirements for packaging hygiene and consistency. The Sachet Counting Sorter not only avoids cross-contamination caused by manual contact but also ensures that each sachet is accurately positioned, which is crucial for subsequent processes such as automatic cartoning with instructions and batch coding. For manufacturers, the application of Pouch Sorting Machine can reduce labor costs by 30%-50% while improving production efficiency by 2-3 times, making it an indispensable key equipment in the intelligent transformation of pharmaceutical packaging.

The Working Principle of Sachet Sorting Machine Automatic

The working principle of the Sorting Machine is based on the combination of mechanical transmission and intelligent detection, which can be divided into five core stages: feeding, conveying, sorting, detection, and output. Each stage is closely linked to ensure the sorting smoothness and accuracy.

First, in the feeding stage, irregularly stacked pharmaceutical sachets are poured into the large-capacity hopper of the Sachet Sorting Machine. The hopper is usually designed with a multi-level composite feeding structure, which can realize pressure-free feeding of sachets and avoid sachet damage caused by excessive stacking pressure. Some advanced models are also equipped with an automatic cleaning function, which can empty the remaining sachets in the hopper to facilitate material replacement and equipment maintenance.

Next is the conveying stage. The conveyor belt in the hopper transports the sachets to the low-speed roller group. The conveying system of the Sorting Sachet Machine is usually composed of multi-level rollers (low-speed, medium-speed, and high-speed) and conveyor belts. By utilizing the speed difference between different rollers, the sachets are gradually separated from the stacked state and transported forward one by one. To prevent belt deviation, many high-end Sorting Bag Machines adopt center positioning conveyor belts, which can automatically adjust the position of the conveyor belt during operation to ensure stable conveying.

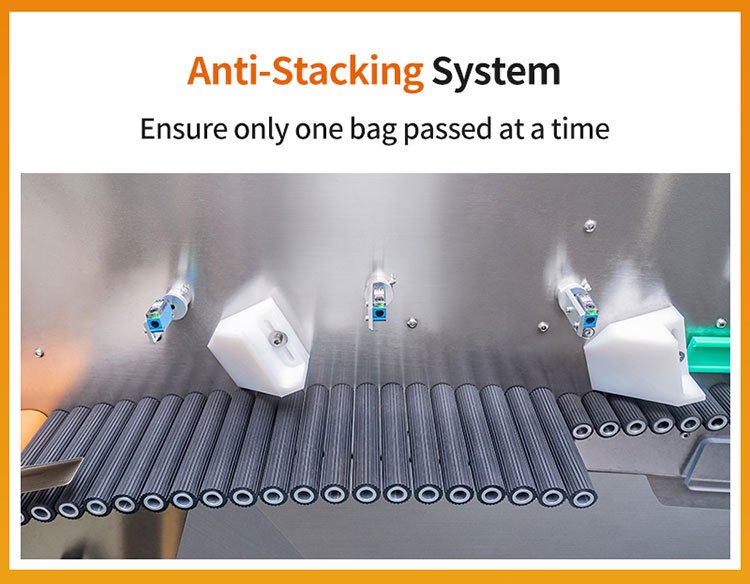

The sorting stage is the core part of the Sachet Automatic Sorting Machine. Under the drive of the servo motor, the sorting rollers adjust the posture of the sachets through precise speed control. For example, for horizontal sachets that are prone to jamming, the system can realize horizontal pouch rejection through preset programs. Specifically, when the photoelectric sensor detects a jammed horizontal sachet, the control system will immediately issue a command to activate the rejection mechanism, and the jammed horizontal pouches are rejected in real-time, ensuring that only sachets with correct postures enter the next process. This real-time rejection function effectively avoids production line shutdowns caused by material jamming and improves the continuity of production.

In the detection stage, the Sachet Auto Sorting Machine is equipped with high-precision photoelectric sensors and image recognition systems to monitor the conveying state of the sachets in real-time. The sensors can detect parameters such as the position, posture, and spacing of the sachets, and feed the data back to the motion control system. If abnormal sachets (such as damaged sachets, empty sachets, or misaligned sachets) are detected, the system will not only trigger the rejection mechanism but also record the abnormal data for subsequent quality analysis.

Finally, in the output stage, the sorted sachets are conveyed to the next equipment (such as Bag Sorting Counting Machine or Bag Collating Counting Machine) at a stable speed and uniform spacing. The output end of the Machine is usually designed with a flexible connection structure, which can be seamlessly docked with various subsequent equipment to realize the automation of the entire packaging line.

Core Components of Sachet Sorting Machine: Guaranteeing Stability and Precision

The stable and precise operation of the Sachet Sorting Machine relies on the coordinated work of multiple core components. Each component is designed with high standards to adapt to the strict requirements of the pharmaceutical industry. The main core components include the hopper, conveying system, drive system, detection and control system, and rejection mechanism.

1. Hopper: Pressure-Free Feeding, No Residue

The hopper of the Sachet Sorting Machine is usually made of 304 stainless steel, which meets the GMP (Good Manufacturing Practices) standards in the pharmaceutical industry and is easy to clean and disinfect. The large-capacity design (usually 50-100L) can reduce the frequency of feeding and improve production continuity. The multi-level composite feeding structure inside the hopper can buffer the sachets, avoid direct impact between sachets, and realize pressure-free feeding. In addition, some high-end models are equipped with an automatic cleaning device, which can automatically clean the hopper after production, ensuring no residual sachets and avoiding cross-contamination between different batches of products.

2. Conveying System: Stable Conveying, No Deviation

The conveying system is composed of conveyor belts, rollers, and guide plates. The conveyor belt is made of food-grade and pharmaceutical-grade materials, which are wear-resistant, high-temperature resistant, and non-toxic. The center positioning design of the conveyor belt can effectively prevent belt deviation, ensuring that the sachets are always conveyed along the correct path. The rollers are made of high-precision aluminum alloy or stainless steel, and the surface is treated with anti-slip technology to increase the friction between the rollers and the sachets, ensuring that the sachets are not slipping during conveying. The speed of the conveyor belt and rollers can be steplessly adjusted according to the production needs, adapting to different specifications and materials of sachets.

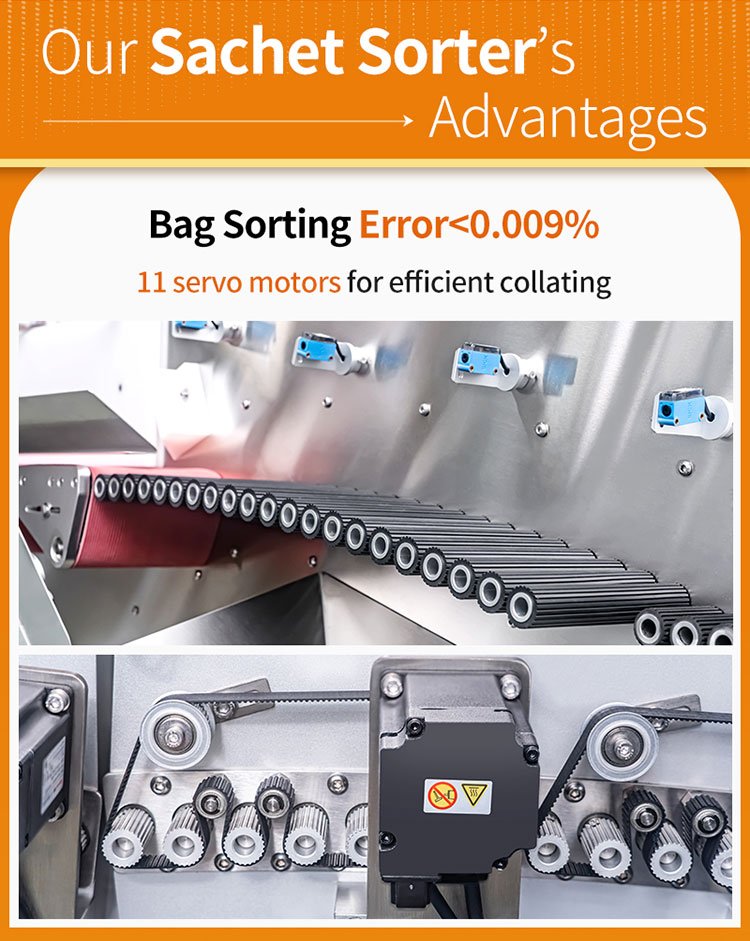

3. Drive System: Precise Control, Stable Operation

The drive system of the Sachet Sorting Machine is mainly composed of servo motors and reducers.Multiple groups of servo motors drive the feeding rollers, conveying rollers, and sorting rollers respectively, and the motion control system realizes coordinated control of each motor. This multi-axis servo intelligent control mode can ensure that the speed difference between different rollers is accurately controlled, realizing various sorting modes such as dispersion, sequence, and stable spacing. The reducer is used to adjust the output speed and torque of the motor, ensuring that the rollers operate at a stable speed, which is the key to improving the sorting precision.

4. Detection and Control System: Real-Time Monitoring, Intelligent Adjustment

The detection and control system is the "brain" of the Sachet Sorter Machine, consisting of photoelectric sensors, image recognition cameras, and a PLC (Programmable Logic Controller) control system. The photoelectric sensors are installed at key positions such as the feeding end, sorting end, and output end, which can detect the presence, position, and posture of the sachets in real-time. The image recognition camera can capture the details of the sachets (such as printing quality and sachet shape) and compare them with preset standards to identify abnormal sachets. The PLC control system processes the data collected by the sensors and cameras, and issues control commands to the drive system and rejection mechanism in real-time. For example, when the sensor detects a jammed horizontal sachet, the PLC system will immediately adjust the speed of the relevant rollers and activate the rejection mechanism to realize real-time rejection of the jammed sachet. Operators can set parameters such as sorting speed and sachet spacing through the interface, and view production data and fault prompts in real-time.

5. Rejection Mechanism: Fast Response, No Damage

The rejection mechanism is an important component to ensure the quality of sorting, which is usually composed of cylinders, push plates, and guide grooves. When the detection system identifies abnormal sachets (such as jammed horizontal sachets, damaged sachets, or empty sachets), the cylinder drives the push plate to quickly push the abnormal sachets into the guide groove, and the abnormal sachets are collected in a dedicated container. The rejection mechanism has the characteristics of fast response (response time ≤ 0.1s) and gentle action, which can avoid damage to normal sachets while ensuring the rejection effect. Some advanced models also adopt a non-contact rejection method (such as air blowing), which further reduces the risk of sachet contamination.

IPv6 network supported

IPv6 network supported