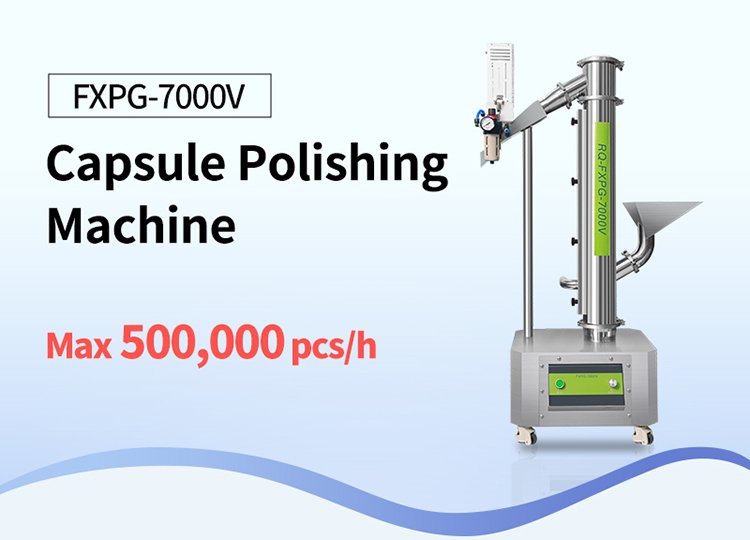

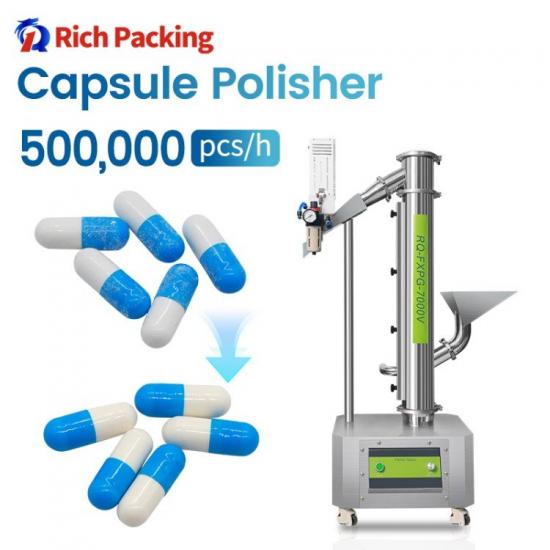

Capsule Polishing Machine Pharmaceutical

*** Technical parameter

| Name | high speed capsule polishing machine |

|

Production capacity |

500,000 pcs/h |

|

Power |

380/220V 50Hz |

|

Applicable capsule |

000, 00, 0, 1, 2, 3, 4, 5# |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

The capsule polisher is a kind of equipment specially used in the pharmaceutical, health care and other industries. FXPG-7000V medicine capsule polisher is mainly used for surface polishing of capsules and tablets. Its core functions include removing dust and debris from the surface of capsules, improving the smoothness of capsules, and removing unqualified products such as empty shells or broken capsules. This equipment is a supporting equipment for capsule filling machines and is widely used in the pharmaceutical, health care and food industries to improve the appearance quality and production standardization of products.

Applicable industries and scenarios of capsule polishing machine

Pharmaceutical companies

In pharmaceutical companies, capsule polishers are indispensable equipment in the medicine production process. It can effectively remove dust and impurities on the surface of capsules, so that when the capsules are packaged and bottled in the next step, the high-precision operation of the capsule blister packaging machine and the capsule counting machine is not affected, so that it meets the pill production specifications. The FXPG-7000V capsule polisher has a production capacity of up to 500,000 capsules/hour, which can efficiently process a large number of capsules to meet the needs of large-scale production.

Health care and food industry

In the health care and food industries, automatic capsule polishers also play an important role. For example, for health products such as vitamin capsules and pill capsules, the polisher's efficient cleaning and intelligent waste rejection function meet consumers' demand for high-quality capsule health products and foods.

Main features of pharmaceutical capsule polishing machine

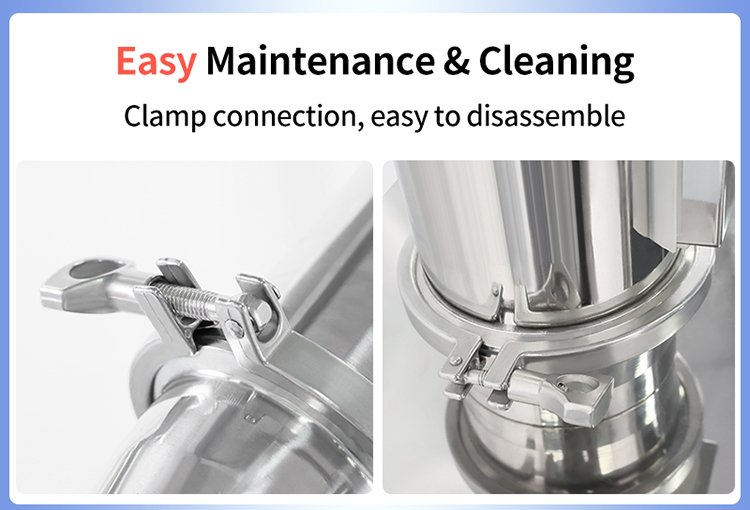

Meet cGMP standards

The capsule polisher strictly follows the cGMP (dynamic pharmaceutical production quality management specification) standard to ensure the hygiene and safety of the production process. All parts that come into contact with pills are made of stainless steel or corrosion-resistant materials, which not only have good corrosion resistance but also prevent contamination of drugs. For example, key components such as polishing cylinders and brushes are made of high-quality SUS316L stainless steel materials, which meet cGMP specifications. This high standard of material selection and manufacturing process enables the capsule polisher to effectively avoid cross-contamination during the pill production process, ensure the quality and safety of drugs, and meet the strict production specifications of the pharmaceutical industry.

Energy-saving and environmental protection characteristics

The capsule polisher machine performs well in energy saving and environmental protection. It adopts an air-blowing waste removal device to collect and recycle dust and debris on the surface of the capsule by negative pressure adsorption, avoiding the direct discharge of dust into the air, thereby reducing pollution to the environment. In addition, compared with traditional equipment, the energy consumption of the capsule polisher is significantly reduced, and the energy saving effect reaches 50%. For example, in actual operation, its low-energy motor and optimized airflow design not only reduce energy consumption, but also reduce the operating cost of the equipment, bringing significant economic benefits to the enterprise, and also meet the requirements of modern industry for energy conservation and environmental protection.

Flexible adjustment function

The capsule polishing machine automatic has a flexible adjustment function and can adapt to the polishing needs of different capsules or tablets. Its speed can be adjusted according to the size, shape and material of the capsule to ensure the consistency and optimization of the polishing effect. For example, for smaller capsules, the speed can be appropriately reduced to avoid excessive friction and damage to the capsule; while for larger capsules, the speed can be increased to improve the polishing efficiency. This flexible adjustment function enables the capsule polisher to be widely used in different types of capsules and tablets, meet diverse production needs, and enhance the versatility and applicability of the equipment.

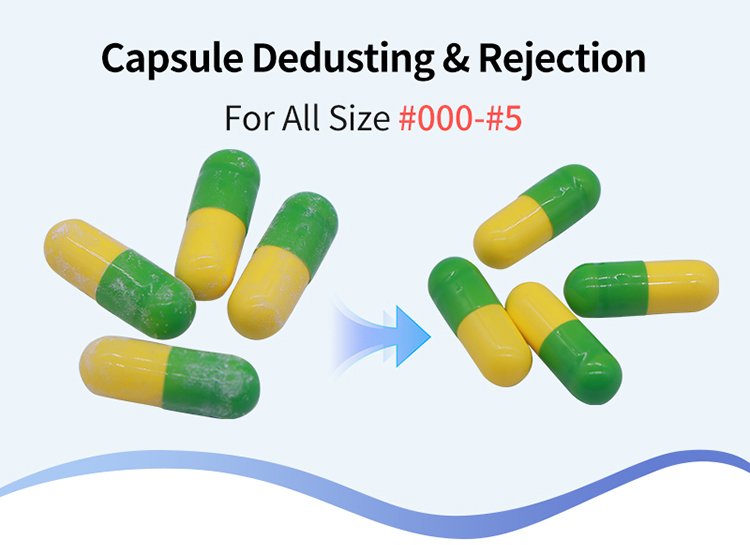

Intelligent rejection mechanism

The capsule deduster is equipped with an advanced intelligent rejection mechanism that can efficiently reject unqualified products. Through the action of positive pressure gas, unqualified products such as insufficient weight and empty capsules are blown into the rejection hopper, while qualified capsules fall smoothly to the discharge port. This intelligent rejection function not only improves the qualified rate of products, but also reduces the workload of manual screening and improves production efficiency. For example, in actual production, the intelligent rejection mechanism can quickly identify and reject unqualified capsules to ensure the quality and consistency of the final product, thereby improving the production efficiency and product quality of the enterprise.

Structure and working principle of capsule sorter

Core component composition

The core components of the high speed capsule polishing machine include hopper, polishing cylinder, brush, vacuum cleaner and discharge hopper. These components work together to ensure the polishing efficiency and reliability of the capsule polishing process.

The hopper is the entrance part of the capsule polishing machine. In addition to storing the capsules to be polished, it can also be used as a device for the high-speed capsule filling machine. The hopper size and shape of the FXPG-7000V capsule polishing machine are scientifically designed, which is very convenient to connect with the high-speed NJP capsule machine to ensure the efficient operation of the equipment production line.

The polishing cylinder is the core area of capsule polishing, and is equipped with polishing elements such as brushes. The design of the polishing cylinder is usually cylindrical with a smooth inner wall to reduce the wear of the capsule during the polishing process. The length and diameter of the polishing cylinder are optimized according to the production capacity of the equipment and the size of the capsule to ensure the best balance between polishing effect and production efficiency.

The brush is also a key component of capsule polishing. Its function is to remove dust and debris from the capsule surface by friction with the capsule surface through high-speed rotation. The brush is usually made of soft and durable materials like as nylon or polyester to avoid scratching the capsule surface. The speed of the brush can be adjusted according to the type of capsule and polishing requirements. For example, for smaller capsules, the speed of the brush can be set to about 1000 revolutions per minute, while for larger capsules, the speed can be appropriately increased to about 1500 revolutions per minute to ensure the polishing effect.

The vacuum cleaner is used to collect dust and debris generated during the polishing process to keep the inside of the equipment and the production environment clean. Its working principle is to suck dust and debris into the collection bag or filter of the vacuum cleaner through negative pressure adsorption. The power and air volume of the vacuum cleaner are designed according to the polishing efficiency and dust generation of the equipment. For example, the vacuum cleaner equipped with the FXPG-7000V capsule polisher has a power of up to 1.5 kilowatts and an air volume of 1,000 cubic meters per hour, which can effectively collect dust generated during the polishing process to prevent it from polluting the environment.

The waste removal mechanism of the capsule polisher

It is an important manifestation of its intelligence, and its principle is based on positive pressure airflow separation technology.

Positive pressure airflow separation: During the polishing capsules process, when the capsule passes through the polishing cylinder, the positive pressure airflow will act on the capsule. Qualified capsules will fall smoothly to the discharge port due to their heavy weight; and unqualified capsules, such as empty shells or broken capsules, will be blown into the waste bucket by the positive pressure airflow due to their light weight. This separation mechanism takes advantage of the weight difference of the capsules and achieves efficient removal of unqualified capsules by precisely controlling the pressure and direction of the airflow. In actual production, the intelligent waste removal mechanism can increase the rejection rate of empty shell capsules to more than 98%, significantly improving the qualified rate of products. In addition, the design of the waste bin in capsule polishing machine usually has automatic collection and cleaning functions, which can easily recycle unqualified capsules and reduce the workload of manual operations.

IPv6 network supported

IPv6 network supported