NJP Serise Capsule Machine Pharmaceutical

*** Technical parameter

| Name | high speed capsule machine |

|

Production capacity |

330,000 pcs/h |

|

Power |

380/220V 50Hz |

|

Total power |

11.0KW |

|

Applicable capsule |

000, 00, 0, 1, 2, 3, 4, 5# |

|

Filling error |

Western medicine:±3% Chinese medicine:±4% |

|

Applicable product |

Powder、granule、pellet、tablet |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

Technological Innovations and Patent Achievements of the NJP 5500D Capsule Filling Machine

The NJP 5500D high-speed powder and granule capsule filling machine has achieved multiple innovations in design and functionality, setting it apart from similar equipment and making it an ideal choice for filling Chinese and Western medicines, as well as health supplements.

Pneumatic Feeding Technology

The high speed capsule machine adopts a novel pneumatic feeding method, particularly suitable for filling materials with poor flowability. Compared to traditional feeding methods, this technology significantly improves filling accuracy, reduces material waste, and ensures the stability and consistency of the filling process. In practical applications, for materials with high viscosity or uneven particle sizes, the pneumatic feeding technology can markedly enhance filling efficiency and minimize production interruptions caused by material flow issues.

Structured and Modular Design

The capsule encapsulation machine features a structured and modular design, offering simple operation and an extremely low failure rate. This design facilitates easier maintenance and upgrades, with the entire mold set replaceable in just 15 minutes, greatly reducing downtime and improving production efficiency for pharmaceutical companies. This ensures adaptability to diverse production needs and guarantees continuous production.

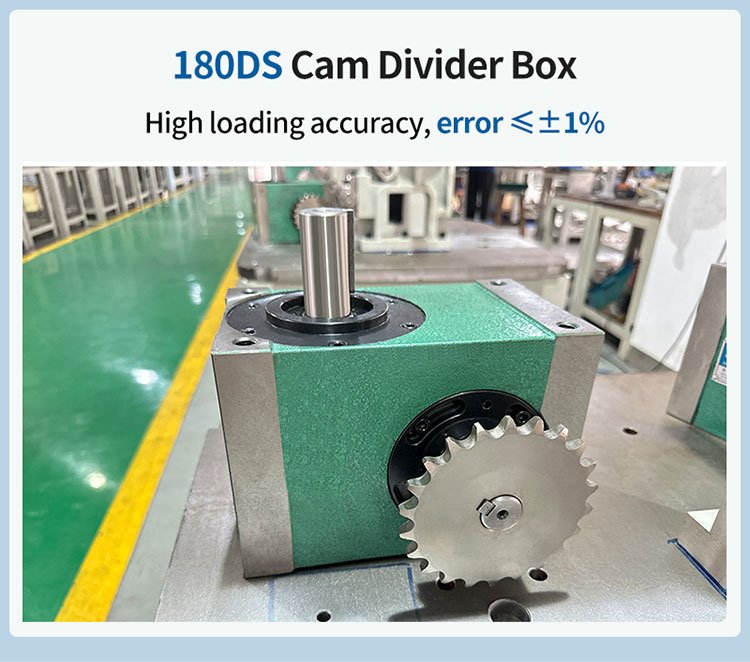

Innovations in Lubrication and Sealing Systems

The automatic capsule filling machine incorporates a one-time cam-injected lubrication system that ensures smooth transmission of the drive mechanism without oil dripping, complying with cGMP requirements. Additionally, the patented turret design, equipped with SIL-imported silicone rubber seals, provides excellent sealing performance with no risk of dust infiltration. This innovative design not only enhances the stability and reliability of the NJP 5500D but also maintains a clean production environment and safeguards drug quality in large-scale pharmaceutical factories.

Positive Air Pressure Sealing Technology

The powder and granule capsule encapsulator machine utilizes a nationally patented turret design, where the interior is filled with positive air pressure to create an air pressure differential between the inside and outside, completely preventing external dust ingress. This technology effectively eliminates dust contamination, ensuring the purity and quality of capsule medications and meeting stringent pharmaceutical production standards.

Surface Treatment of Capsule Filling Molds

The mold holders, filling dose control rods, upper and lower mold holes, and dosing discs undergo electropolishing treatment. This not only resolves issues such as material stickiness, adhesion, and moisture absorption but also improves the coordinated flowability of each station in the high speed capsule filling machine automatic.

Upgraded Electrical Configuration

The control system employs world-renowned brands, including Siemens, Omron, Schneider, and Beck, ensuring easy maintenance. Customers can readily purchase spare parts and access local service support for inspections and upkeep. The intuitive HMI interface features automatic alarms and shutdowns for powder shortage, capsule shortage, or mechanical failures, along with fault diagnosis prompts. These upgrades not only enhance the durability and reliability of the NJP capsule filling machine but also enable future intelligent upgrades and modifications.

Detailed Explanation of Three Invention Patents

The three invention patents of the NJP 5500D capsule filling machine further solidify its technological leadership in the industry. These patents cover critical technical aspects of the equipment, providing robust support for its high performance and reliability.

Turret Design Patent

This patent involves the structure and sealing technology of the turret in the empty hard gelatine capsule filling machine. By maintaining positive air pressure inside the turret to create an air pressure differential, combined with ultra-sealing technology and PTFE oil-free bearings, the probability of dust ingress is reduced to one-tenth of that of competitors. This patented technology elevates the NJP 5500D to industry-leading levels in sealing performance and reliability.

Filling Mechanism Patent

The filling mechanism of the fully automatic capsule filling machine employs three-dimensional adjustment technology, ensuring even force distribution on the dosing disc and perpetual leveling for quick and precise dosage adjustment. This design not only improves filling accuracy but also allows for the integration of an internal powder recovery system, achieving zero material waste. By recycling powder generated during the capsule filling process, it enhances economic efficiency.

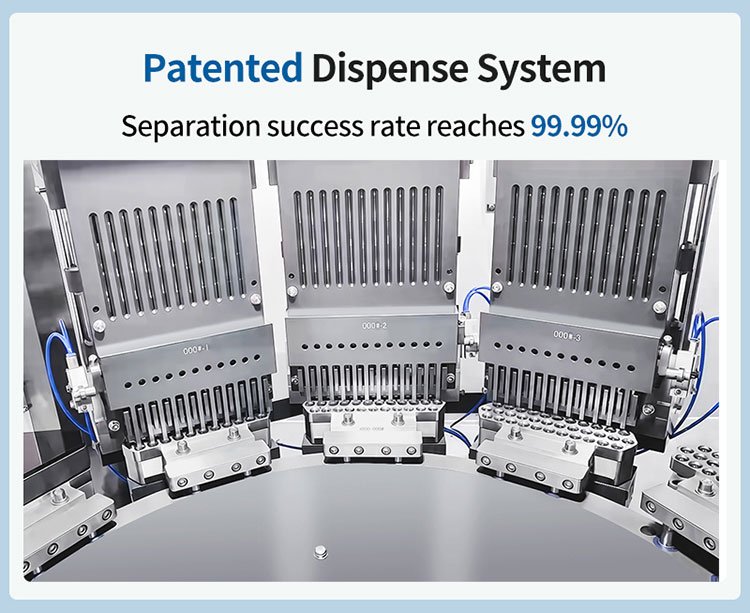

Capsule Ejection Mechanism Patent

The capsule ejection mechanism of the capsule filling machine fully automatic has been granted a national utility model patent. It utilizes a multi-outlet cam-pushing design, where the ejector pins perfectly match the curvature of the capsules, preventing scratches or damage during ejection. This innovative design not only boosts ejection efficiency but also ensures the surface integrity of plant-based or animal-based gelatin capsules, maintaining the drug quality of capsules at an industry-leading level.

Core Functions and Performance Advantages of the Equipment

Automated Production Process

The NJP 5500D high speed pharmaceutical capsule making machine achieves fully automated production, encompassing capsule feeding, separation, filling, locking, defect removal, and finished product output. This automated workflow not only significantly enhances production efficiency but also reduces errors and contamination risks associated with manual operations. Key aspects of its automation include:

Automatic Capsule Feeding and Separation

The gelatin capsule filling machine automatically performs capsule feeding and separation, with a success rate of up to 99.99%. This high success rate ensures minimal production interruptions and material waste due to separation failures, guaranteeing continuous and stable production.

Automatic Filling and Locking

During the filling stage, the auto capsule filling machine employs advanced pneumatic feeding technology and a three-dimensional adjustable filling mechanism. It can also be equipped with a granule filling device to precisely fill powder or granules into capsules, by rapid locking.

Automatic Defect Removal and Finished Product Output

The hard gel capsule making machine features an automatic defect removal function, capable of identifying and rejecting substandard capsules, achieving a finished product qualification rate of 99.8%. This high qualification rate significantly reduces defect rates and production costs. Meanwhile, finished products are automatically output for subsequent packaging and storage.

Intelligent Control and Monitoring

The NJP series capsule filling machine is equipped with a Siemens HMI interface, featuring automatic alarms and shutdowns for powder shortage, capsule shortage, or mechanical failures, along with fault diagnosis prompts. This intelligent control system monitors real-time production parameters, promptly identifying and addressing potential issues to ensure stable operation. Additionally, the machine can record and display shift production, cumulative output, and shift operation time. It can also be configured with a printer to generate production dates, batch numbers, and codes on demand, further improving traceability and management efficiency.

IPv6 network supported

IPv6 network supported