Automatic Empty Pill Capsule Filling Machine NJP-1500D

Our njp1500d fully active sub high speed capsule filling machine is an excellent D-type capsule making machine. The volume of njp1500d is smaller than that of similar products, but the production speed is also very fast, reaching 1500 capsules per minute. Njp1500d is different from the old product in that it performs the disposal and upgrading of type C beside the turntable, filling and waste disposal tasks.

*** Applications

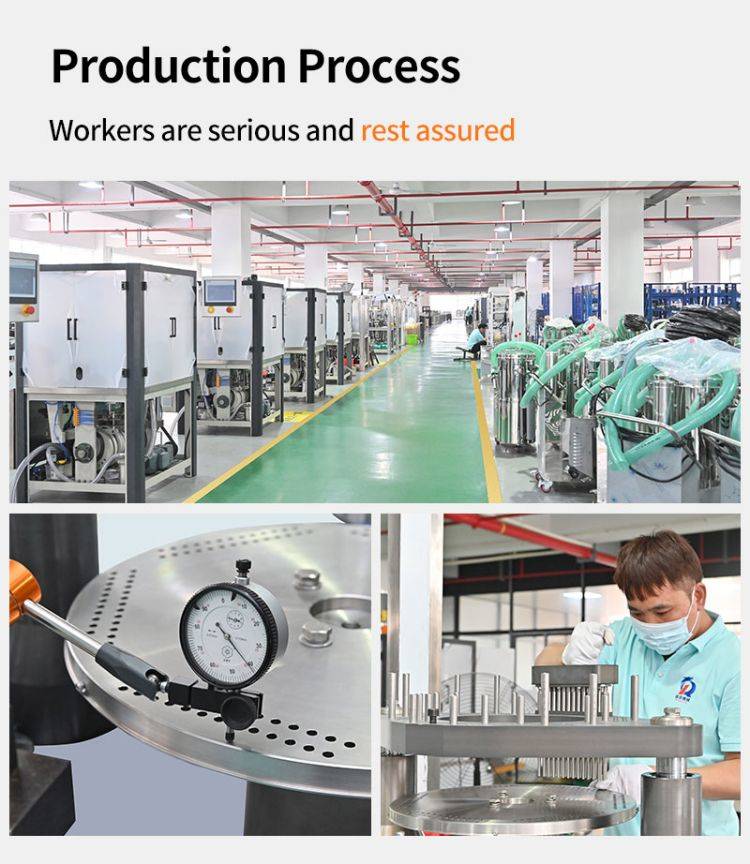

Excellent machine material of NJP1500D, The whole fuselage is made of 304 high quality stainless steel, while the core part is made of seven series aviation aluminum in 1500D.

The Double sealing rubber ring is used on 1500d. It's better for the long life of the 1500D machine.

Perfect detection system of 1500D. Ensure the customer's long-term operation and production of 1500D.

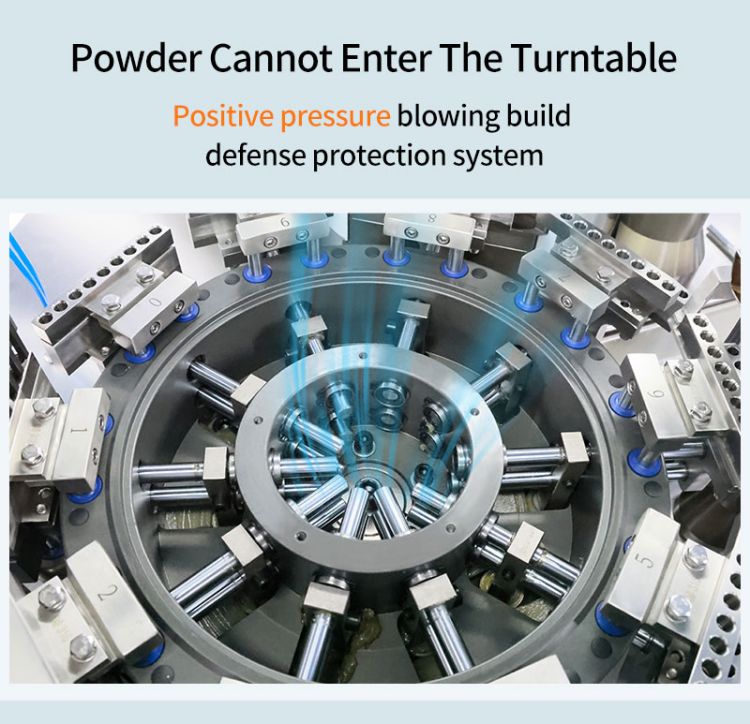

After our long-term market investigation and field research in capsule making machine. In the process of when filling capsules, there will be some errors such as the incorrect separation of capsules or the capsule rupture or lack of materials or material overflow and so on. In order to improve the working accuracy of the 1500D capsule filling machine, we installed a vacuum suction device after the filling material working position 1500D which is the function of weeding waste. If the 1500D working position is wrong, the 1500D system will automatically detect the waste port. Through the 1500D high-pressure air, the capsule shell is separated from the material and the material is finally put into the 1500D recycling bucket, so as to achieve the purpose of no waste in 1500D.

Technical parameter

| Name | Automatic hard gelatin capsule filling machine |

|

Production capacity |

90000 pcs/h |

|

Net weight of machine |

1200Kg |

|

Overall size of machine |

900×870×1950mm |

|

Power |

380/220V 50Hz |

|

Total power |

5.5KW |

Want to know about this product?

Feel free to contact me, and I will be more than happy to answer all of your questions.

NJP-1500D Automatic Capsule Filling Machine: Addressing Pain Points in Capsule Filling

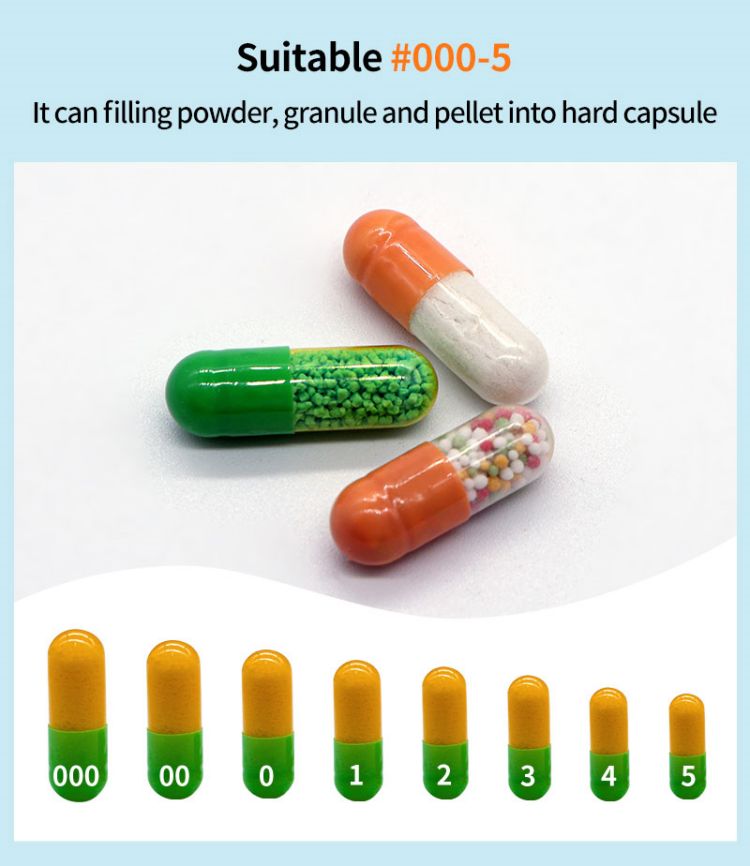

In the pharmaceutical industry, the efficiency, precision, and compliance of the capsule filling process directly impact pharmaceutical production schedules and quality safety. As a manufacturer specializing in the R&D and production of pharmaceutical and packaging machinery, Rich Packing is well aware of the industry's pain points: traditional semi-automatic capsule machines suffer from low output, high reliance on manual labor, inefficient capsule loading, and inaccurate dosing, failing to meet the large-scale and standardized production needs of modern pharmaceutical enterprises. To address this, we have launched the NJP-1500D Automatic Pharmaceutical Capsule Filling Machine. With its flexible material adaptability (compatible with powders, granules, and pellets), precise filling technology, and efficient automated processes, it has become an ideal choice for medium to large-sized pharmaceutical enterprises and nutraceutical manufacturers, injecting strong impetus into the production of solid dosage form capsule products.

Versatility of the NJP Capsule Machine: Covering Diverse Materials and Mainstream Capsule Sizes

One of the core advantages of the NJP-1500D Powder Granule Capsule Filling Machine lies in its broad applicability. It accurately matches the diverse production needs of pharmaceutical enterprises in terms of both material forms and capsule specifications, eliminating the need for frequent replacement of core components and significantly reducing production changeover costs.

Material Compatibility: From Powders to Pellets, Balancing Properties and Precision

The NJP-1500D achieves full material coverage for common material types in the pharmaceutical industry:

- For powder materials with good fluidity and temperature sensitivity (e.g., vitamin powders, traditional Chinese medicine (TCM) mixed powders), the machine adopts a vibratory pneumatic feeding system, which adjusts the material feeding volume by controlling the flip of the feed butterfly valve.

- For powder materials with poor fluidity, high hygroscopicity, and high viscosity, this automatic capsule filling machine uses a screw-type feeding structure to control the feeding speed and filling volume, ensuring a continuous and stable feeding rate for capsule production.

- For granular materials (e.g., sustained-release granules, TCM granules), a specialized granule and pellet feeding system is employed. By adjusting the thickness of the dosage disc to match the feeding volume of granules with different particle sizes, it ensures uniform granular content in each capsule.

In addition, the high speed capsule filling machine reserves two stations, supporting composite filling modes such as "powder + granules" or "powder + pellets" to meet the production needs of compound preparations. For instance, a large U.S. pharmaceutical enterprise produces compound capsules that require simultaneous filling of TCM powder and sustained-release granules. With its dual-station filling design, the NJP-1500D can complete the precise filling of both materials in one operation, eliminating the need for secondary processing and increasing production efficiency by over 40%.

Capsule Sizes: Covering Mainstream Specifications

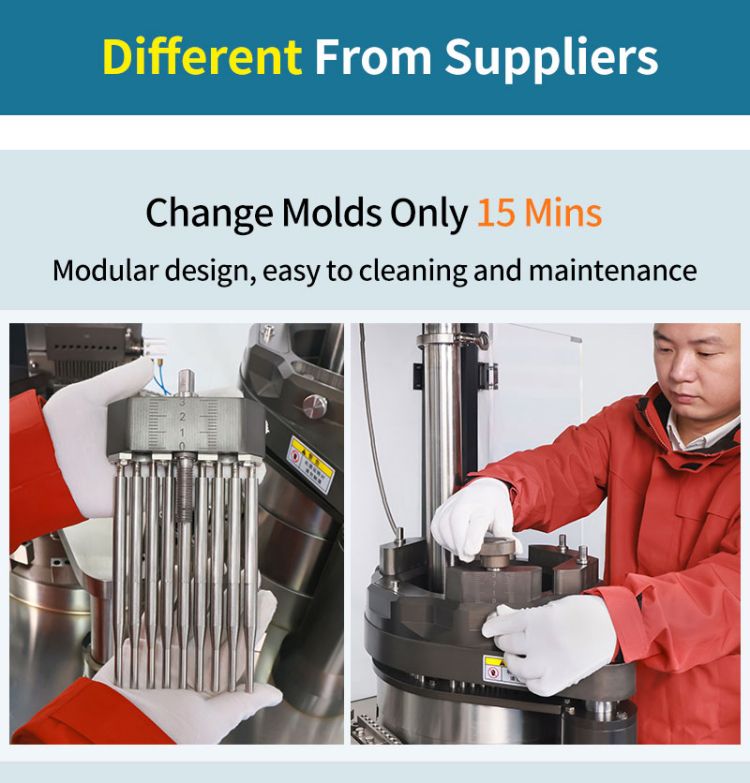

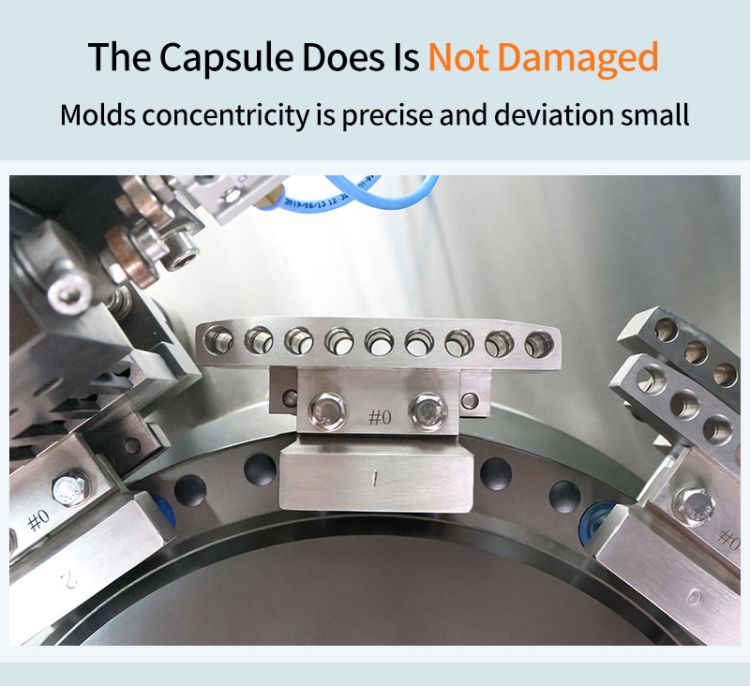

In terms of capsule size compatibility, the NJP-1500D filling capsule machine supports all mainstream empty capsule specifications on the market, including 000, 00, 0, 1, 2, 3, 4, and 5. It enables stable separation, filling, and locking for gelatin capsules, hydroxypropyl methylcellulose (HPMC) capsules, and vegetable capsules alike. The machine is equipped with quick-change capsule molds; changing molds for different sizes takes only 15 minutes, no professional technicians are required, and ordinary workers can complete the process after simple training.

For enterprises with special needs (e.g., customized large-size capsules such as "short and fat" capsules or non-standard size capsules), we offer custom mold services. Based on the capsule parameters provided by the customer, we design exclusive molds and fine-tune the machine's filling system to ensure compatibility and stability. Previously, a health supplement enterprise needed to produce large-dose protein powder capsules. Through custom mold design and equipment debugging, the NJP-1500D automatic capsule filler successfully achieved precise filling of 3g of powder per capsule, with a production capacity of 60,000 capsules per hour, fully meeting the customer's large-scale production needs.

Intelligent Working Principle: Automated Processes Ensuring Precision and Efficiency from the Source

The NJP-1500D Automatic Capsule Filler Machine adopts a "high-precision 100DS indexing box + PLC control system," realizing full-process automation from capsule feeding, separation, filling, and locking to finished product inspection and waste recycling. No manual intervention is required, which not only improves production efficiency but also avoids errors and contamination caused by manual operations.

Step 1: Capsule Feeding and Separation – Stable and Loss-Free

The NJP capsule machine is equipped with a large-capacity capsule hopper (capacity: 5,000 capsules), which uniformly conveys empty capsules to the hopper via a vacuum feeding mechanism. The separation system uses the negative pressure suction principle, and through precise alignment of the upper and lower molds, it efficiently separates capsule caps from bodies, achieving a separation success rate of 99.9% without causing compression damage to the capsules. If individual capsules cannot be separated, the machine automatically identifies them and discharges them through the waste channel to avoid disrupting subsequent processes.

Step 2: Multi-Station Synchronous Filling – Precise and Controllable

After separation, the capsule bodies enter the filling station. The machine activates the corresponding filling module based on the material type:

- Powder materials are filled quantitatively via a screw feeder, with the feeding speed adjustable in real-time via the PLC system (range: 10-50 rpm).

- Granular and pellet materials are filled via dedicated feeders, ensuring a filling volume error of no more than ±0.5% per capsule.

Step 3: Capsule Locking – Compliance-Assured

The filled capsule bodies and caps enter the locking station, where tight locking is achieved through mechanical pressure application. The locking force can be adjusted according to capsule specifications (range: 5-20N) to prevent capsule loosening or deformation. No manual participation is required throughout the process, complying with the "error prevention and contamination prevention" requirements of cGMP for pharmaceutical production.

Step 4: Waste Recycling and Data Recording – Cost Reduction and Traceability

The machine is also designed with a waste recycling system. For capsule shells that fail separation and unqualified finished products, they are collected through dedicated vacuum suction channels. After manual screening, intact capsule shells can be reused, reducing material waste. Meanwhile, the PLC control system automatically records production data, including production time, capacity, pass rate, and filling parameters. The data can be stored for over 1 year, supporting on-machine printing, USB export, or network upload to the enterprise's MES system. This facilitates production traceability and quality control for enterprises, meeting the audit requirements of international regulatory authorities such as the FDA and EMA.

Outperforming Semi-Automatic Models: Five Core Advantages Redefining Capsule Production Efficiency

Compared with traditional semi-automatic capsule filling machines, the NJP-1500D Automatic Capsule Filling Machine achieves comprehensive breakthroughs in efficiency, precision, cost, and compliance, making it the first choice for pharmaceutical enterprises upgrading their production equipment.

Advantage 1: Over 3x Higher Capacity to Meet Large-Scale Needs

Semi automatic capsule machines require manual feeding and capsule separation, with an actual hourly output of no more than 15,000 capsules. In contrast, the NJP-1500D operates fully automatically, with a maximum hourly output of up to 90,000 capsules – more than 5 times that of semi-automatic models.

Take a medium-sized pharmaceutical enterprise as an example: previously, it used 2 semi-automatic capsule machines, requiring 2-3 workers to operate them in coordination. The workers also needed professional training to master filling skills, and could only produce 240,000 capsules per day with 2 hours of operation. After switching to 1 NJP-1500D, only 1 worker is needed to handle feeding, finished product collection, and equipment inspection. The operation interface is a Chinese touchscreen with simple and intuitive parameter settings, allowing workers to be ready for operation after just 1 day of training. With 8 hours of daily operation, it can produce 720,000 capsules – a 3x increase in capacity – while reducing the number of operators by 5, significantly improving production efficiency and cutting production costs.

Advantage 2: Higher Filling Precision to Reduce Quality Risks

Semi automatic capsule filling machine relies on manual control of filling volume, with error rates generally exceeding ±8%, which easily leads to under-filling or over-filling and inaccurate drug dosages. The NJP-1500D controls the error rate within ±0.5% through its precision dosage system. In addition, the machine's automated processes avoid manual contact with materials and capsules, reducing the risk of cross-contamination and complying with the "asepsis and no cross-contamination" requirements of cGMP for pharmaceutical production, helping enterprises pass compliance audits smoothly.

Advantage 3: Stronger Stability to Reduce Downtime

Due to their simple mechanical structure, semi auto filling capsule machines are prone to malfunctions such as jamming and powder leakage, with an average monthly downtime for maintenance of 8 hours. The NJP-1500D uses high-quality components (e.g., Germany's Becker vacuum pumps, Japan's Omron sensors, and Germany's Siemens PLC and touchscreen) and is equipped with an automatic fault diagnosis system that monitors equipment operation status in real-time. If an abnormality occurs, it immediately triggers an alarm and displays the cause of the fault, allowing maintenance personnel to quickly troubleshoot. The machine has a mean time between failures (MTBF) of over 500 hours, with monthly maintenance time of only 1-2 hours, effectively ensuring production continuity.

Advantage 4: Greater Flexibility for Multi-Product Production

The NJP-1500D supports multi-material and multi-size compatibility. When changing materials or capsule sizes, only the corresponding modules and molds need to be replaced, with commissioning time as short as 15-30 minutes. This makes it particularly suitable for nutraceutical enterprises or multi-product pharmaceutical enterprises that need to switch products frequently. For example, a CDMO enterprise undertakes 5-8 capsule contract manufacturing orders per month. After using the NJP-1500D, its product changeover efficiency increased by 80%, and its order delivery cycle was reduced by 20%.

In Summary

As a manufacturer deeply rooted in the pharmaceutical packaging machinery field, we always prioritize "customer interests at the core." The NJP-1500D Automatic Capsule Filling Machine is not only an efficient production equipment but also a strategic partner for enterprises to reduce costs, improve efficiency, and enhance compliance capabilities. Currently, this high-speed capsule filling equipment serves over 200 pharmaceutical enterprises worldwide, including subsidiaries of several Fortune 500 companies, and has won consistent recognition from customers for its stable performance and high-quality services.

If you want to learn more about the detailed parameters and actual production cases of the NJP-1500D, or need a customized capsule filling solution, please visit Rich Packing's official website. We will provide you with one-on-one professional services to help your enterprise achieve capsule production upgrading!

IPv6 network supported

IPv6 network supported